Strengthening method for stress on single plate by using steel reinforced concrete

A technology of single-slab stress and concrete, applied in bridge reinforcement, erection/assembly of bridges, bridge materials, etc., can solve problems such as enhancing the bearing capacity of single beams, difficult to deal with hinge gaps, and affecting reinforcement effects, etc., to increase integrity , improve the carrying capacity, and improve the effect of lateral distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

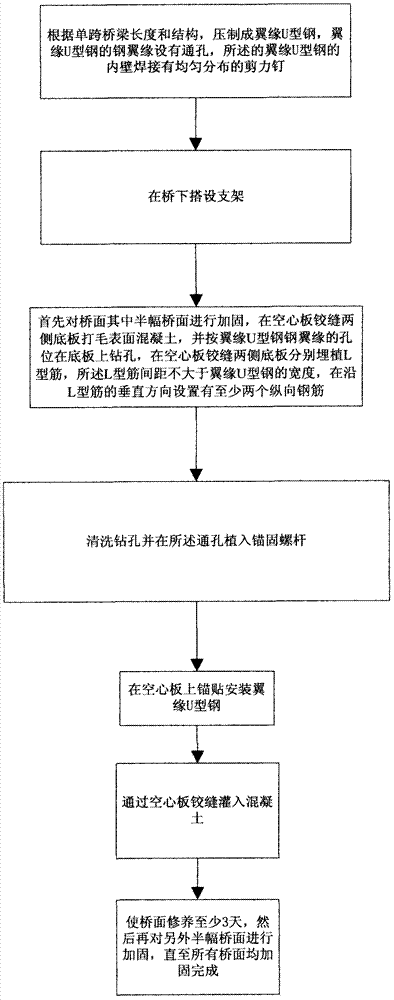

[0021] A reinforcement method for steel-reinforced concrete to deal with the stress of a veneer, comprising the following steps:

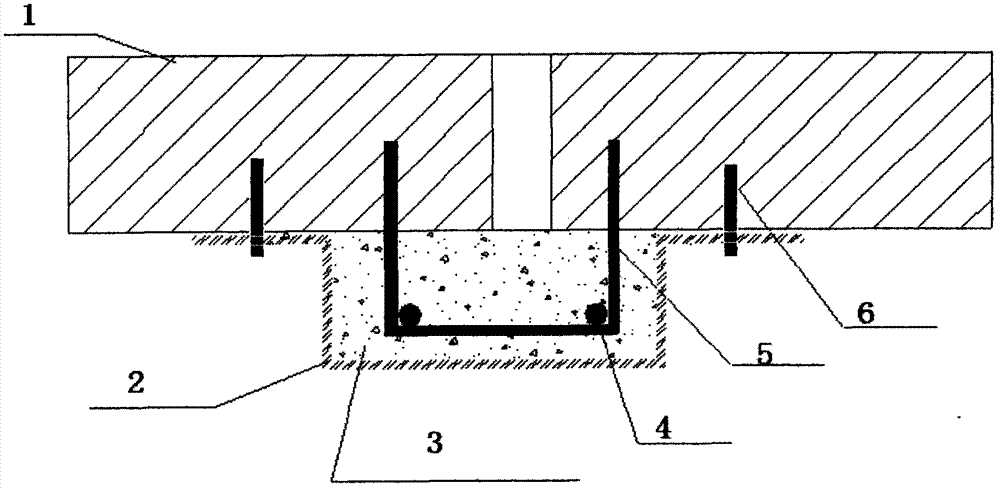

[0022] a. According to the length and structure of the single-span bridge, the flange U-shaped steel 2 is pressed, and the steel flange of the flange U-shaped steel 2 is provided with through holes;

[0023] b. Roughen the concrete 3 on the bottom plate on both sides of the hinge joint of the hollow plate 1, and drill holes on the bottom plate according to the hole position of the flange U-shaped steel 2 steel flange;

[0024] c. cleaning the borehole and implanting the anchor screw 6 in the through hole;

[0025] d. Anchor and install the flange U-shaped steel 2 on the hollow plate 1;

[0026] e. Pour high-strength self-leveling pebble concrete 3 through the hinged joints of the hollow slab 1.

Embodiment 2

[0028] A reinforcement method for steel-reinforced concrete to deal with the stress of a veneer, comprising the following steps:

[0029] a. According to the length and structure of the single-span bridge, the flange U-shaped steel 2 is pressed, and the steel flange of the flange U-shaped steel 2 is provided with through holes;

[0030] b. First, half of the bridge deck is reinforced, and the surface concrete 3 is roughened on the base plate on both sides of the hinge joint of the hollow plate 1, and holes are drilled on the base plate according to the hole positions of the flange U-shaped steel 2 steel flange;

[0031] c. cleaning the borehole and implanting the anchor screw 6 in the through hole;

[0032] d. Anchor and install the flange U-shaped steel 2 on the hollow plate 1;

[0033] e. Pour high-strength self-leveling pebble concrete 3 through the hinge joint of the hollow slab 1;

[0034] f. Let the bridge deck repair for at least 3 days, and then reinforce the other h...

Embodiment 3

[0036] A reinforcement method for steel-reinforced concrete to deal with the stress of a veneer, comprising the following steps:

[0037] a. According to the length and structure of the single-span bridge, the flange U-shaped steel 2 is pressed, and the steel flange of the flange U-shaped steel 2 is provided with through holes, and the inner wall of the flange U-shaped steel 2 is welded with evenly distributed shear studs ;

[0038] b. First, half of the bridge deck is reinforced, and the surface concrete 3 is roughened on the base plate on both sides of the hinge joint of the hollow plate 1, and holes are drilled on the base plate according to the hole positions of the flange U-shaped steel 2 steel flange;

[0039] c. cleaning the borehole and implanting the anchor screw 6 in the through hole;

[0040] d. Anchor and install the flange U-shaped steel 2 on the hollow plate 1;

[0041] e. Pour high-strength self-leveling pebble concrete 3 through the hinge joint of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com