Resilience prevention bridge girder prestress tension device

A tensioning device and prestressing technology, applied in bridges, bridge materials, bridge construction, etc., to achieve the effects of ensuring project quality, preventing springback, and structural improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

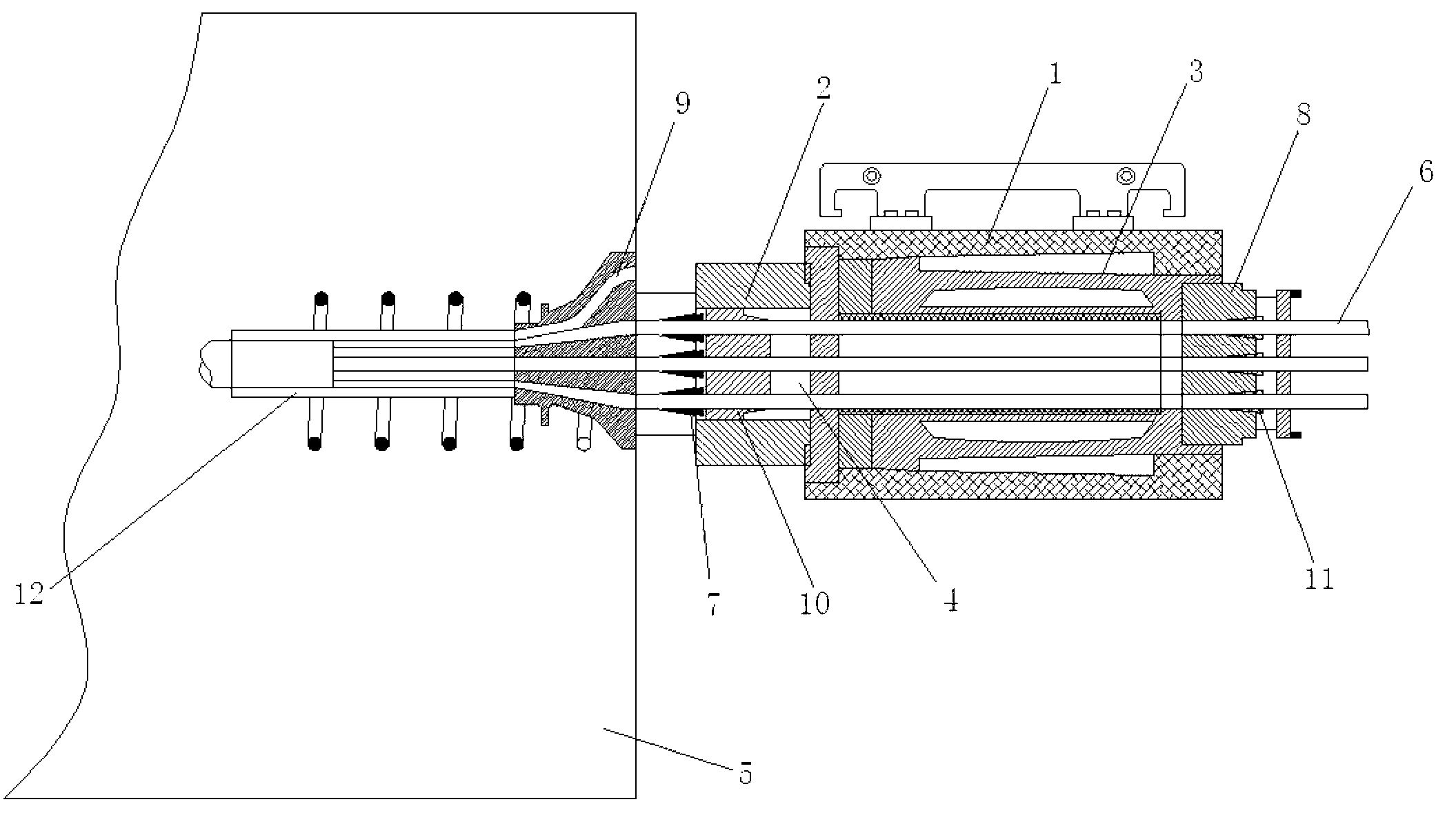

[0012] see figure 1 , a prestressed tensioning device for an anti-rebound bridge, including a bridge 5, a stress hole 12 is arranged on the bridge 5, a steel strand 6 passes through the stress hole on the bridge, and a primary oil cylinder 1 and a secondary oil cylinder are also included 2. The first-stage piston 3 in the first-stage oil cylinder and the second-stage piston 4 in the second-stage oil cylinder move in opposite directions, and the second-stage piston 4 moves toward the direction of the bridge, and the end of the first-stage piston 3 and the second A primary anchor 8 and a secondary anchor 10 are installed and connected to the ends of the primary piston 4 respectively, and the steel strand 6 passes through the secondary anchor 10 and the primary anchor 8 and is fixedly connected thereto. The front end and rear end of the steel strand 6 described above are provided with a front tapered clip 7 and a rear tapered clip 11 respectively, and the front tapered clip 7 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com