Pulp abrasive disc

A technology for grinding sheets and pulp, applied in the field of grinding sheets for grinding machines, can solve problems such as being unsuitable for fibrous or pulp grinding, and achieve the effects of improving material conveying capacity, increasing rubbing area, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

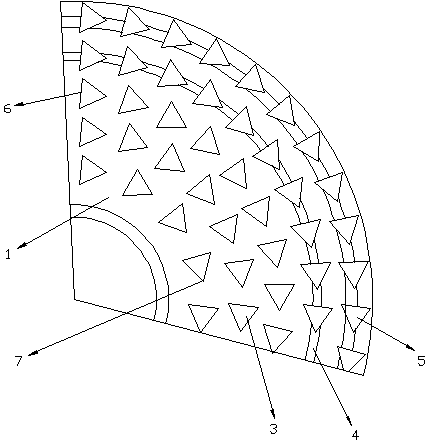

[0023] as attached figure 1 The pulp grinding disc made of high-chromium white iron shown in the figure can be used as a dynamic grinding disc of the grinding machine; the disc surface is an overall disc shape, and there are a plurality of single teeth evenly distributed on the inner side of the disc surface , there are two concentric annular teeth with different radii on the periphery of the disk.

[0024] The ring tooth is composed of a ring tooth root and a plurality of ring teeth, the ring tooth root is in the shape of a complete circle, the ring tooth root is connected to the disk surface, and a plurality of ring teeth are dispersedly connected to the ring tooth root.

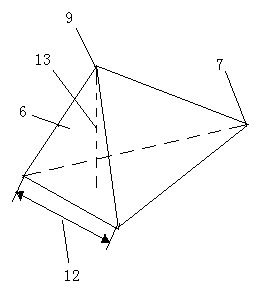

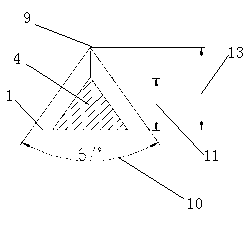

[0025] as attached figure 2 , attached image 3 As shown, the shapes near the tooth heads of the single tooth and the ring tooth are both isosceles triangular pyramids, and the direction of the tooth shape is the tangent direction of the arc at its position, and they are all clockwise. The addendum ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com