Blow-boiling-type slag gathering device

A technology of slag gathering and driving device, which is applied in the field of molten iron pretreatment, can solve the problems that the position and angle of the air blowing pipe cannot be adjusted, the space occupied by the air blowing pipe is large, and the efficiency of slag removal is reduced, and the slag removal time is shortened, the structure is simple, The effect of improving the efficiency of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

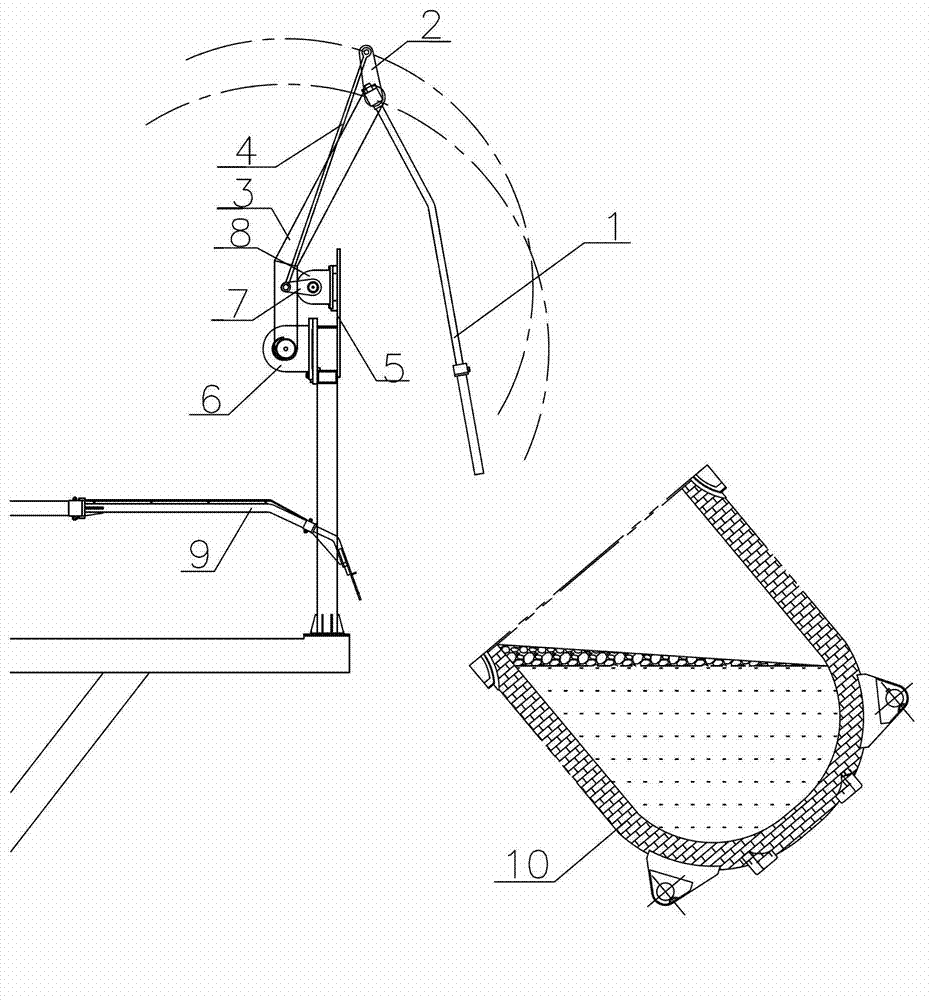

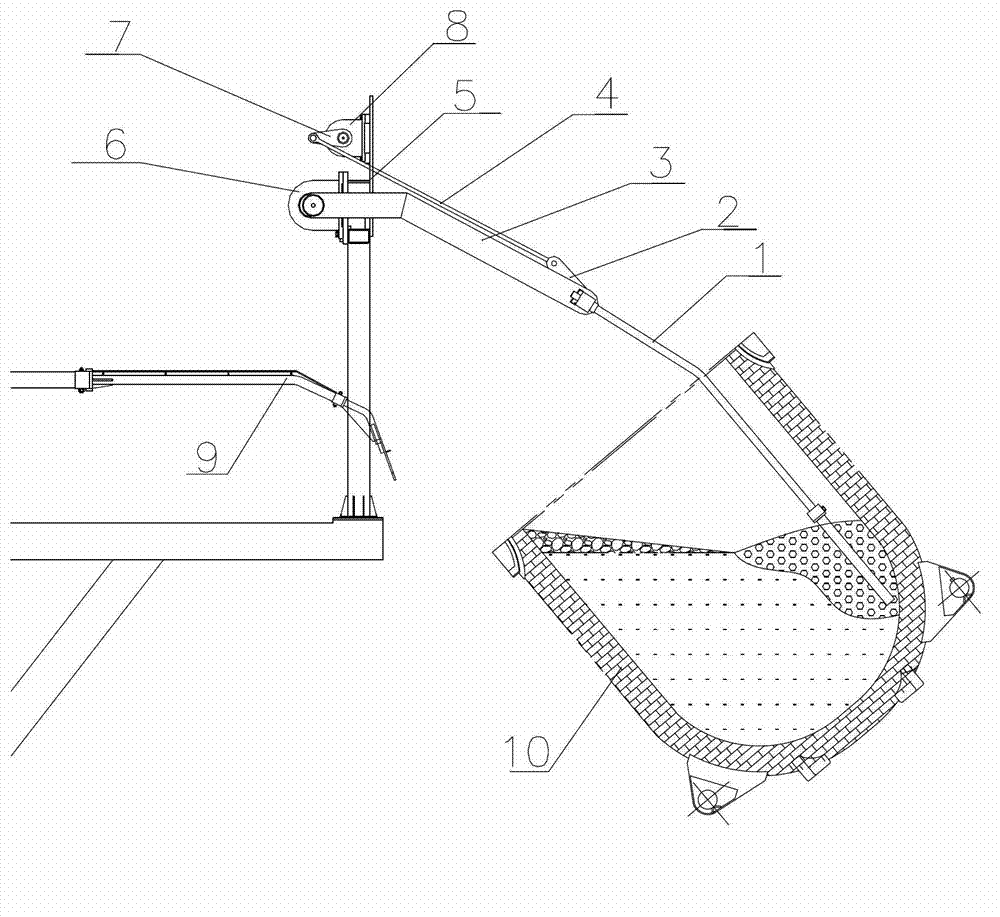

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0017] Such as figure 1 , figure 2 As shown, the blowing type slag gathering device of the present invention includes a frame 5, a first driving device 6, a swing arm 3, a connecting rod 4, a control arm 2 and an air spray gun 1.

[0018] The first driving device 6 is fixed on the frame 5, and the swing arm 3 is driven to rotate by the first driving device 6. The first driving device 6 may be an electric motor, a hydraulic motor or the like. The connecting rod 4 is hinged on the frame 5, and the two ends of the control arm 2 are respectively hinged with the connecting rod 4 and the swing arm 3. The frame 5, the swing arm 3, the connecting rod 4 and the control arm 2 form a four-bar mechanism, which is a double-rocker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com