Nanometer dual-fuel lubricating oil and preparation method thereof

A dual-fuel, lubricating oil technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as unfavorable engine lubrication protection, lubricating oil quality degradation, nitration of ordinary lubricating oil, etc., to improve cold start performance and eliminate mechanical thermal expansion , control the effect of sludge carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of above-mentioned nano dual-fuel lubricating oil comprises the following steps:

[0020] (1) Add the base oil into the reaction kettle and heat the liquid to 60°C;

[0021] (2) Add other components sequentially into the reaction kettle of step (1), keep the temperature at 60°C, and stir at this temperature for 60 minutes;

[0022] (3) filtering the mixed liquid of step (2);

[0023] (4) Transfer the mixed liquid in step (3) to the precipitation kettle, and settle for 24 hours to obtain the finished product.

Embodiment 1

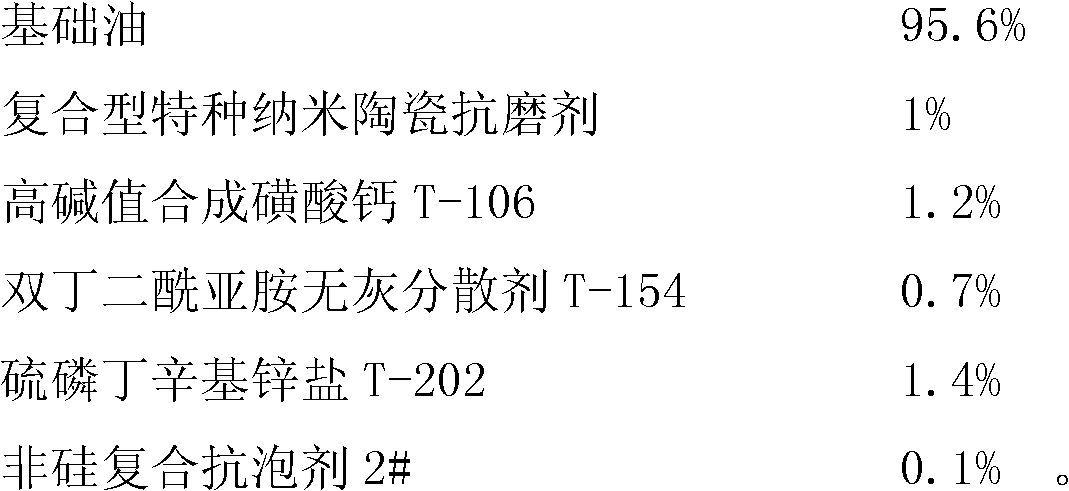

[0025] Select the following components:

[0026]

[0027] Add the above base oil into the reaction kettle, heat the liquid to 60°C, then add other components one by one, keep the temperature at 60°C, stir for 60 minutes, then filter the mixed liquid, and transfer it to the precipitation kettle for precipitation for 24 hours. Made finished product.

Embodiment 2

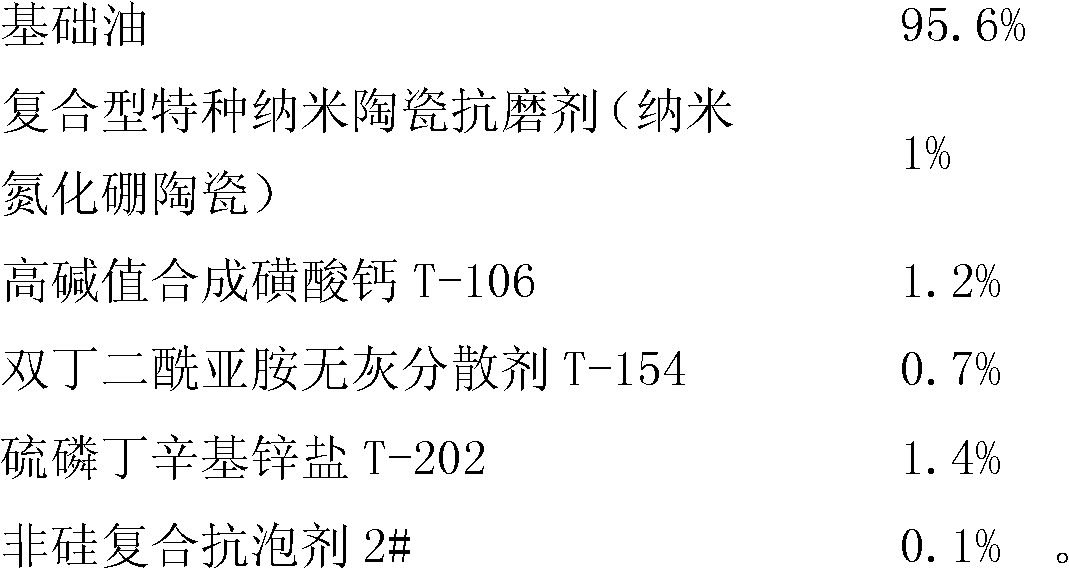

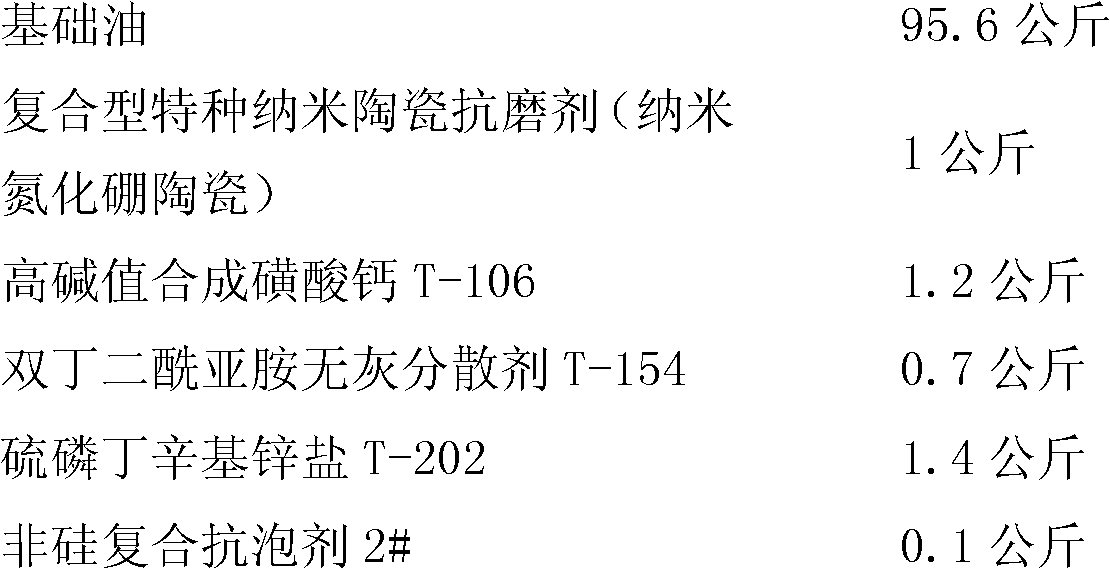

[0029] Select the following components:

[0030]

[0031] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com