Coordinated process extraction method of biological active substances in crayfish by-products

A technology of biologically active substances and extraction methods, which is applied in the field of one-stop extraction of biologically active substances in by-products of crayfish, can solve the problems of incomplete implementation of clean production, environmental pollution by waste liquid, long production cycle, etc., and shorten the production cycle. , uniform color, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

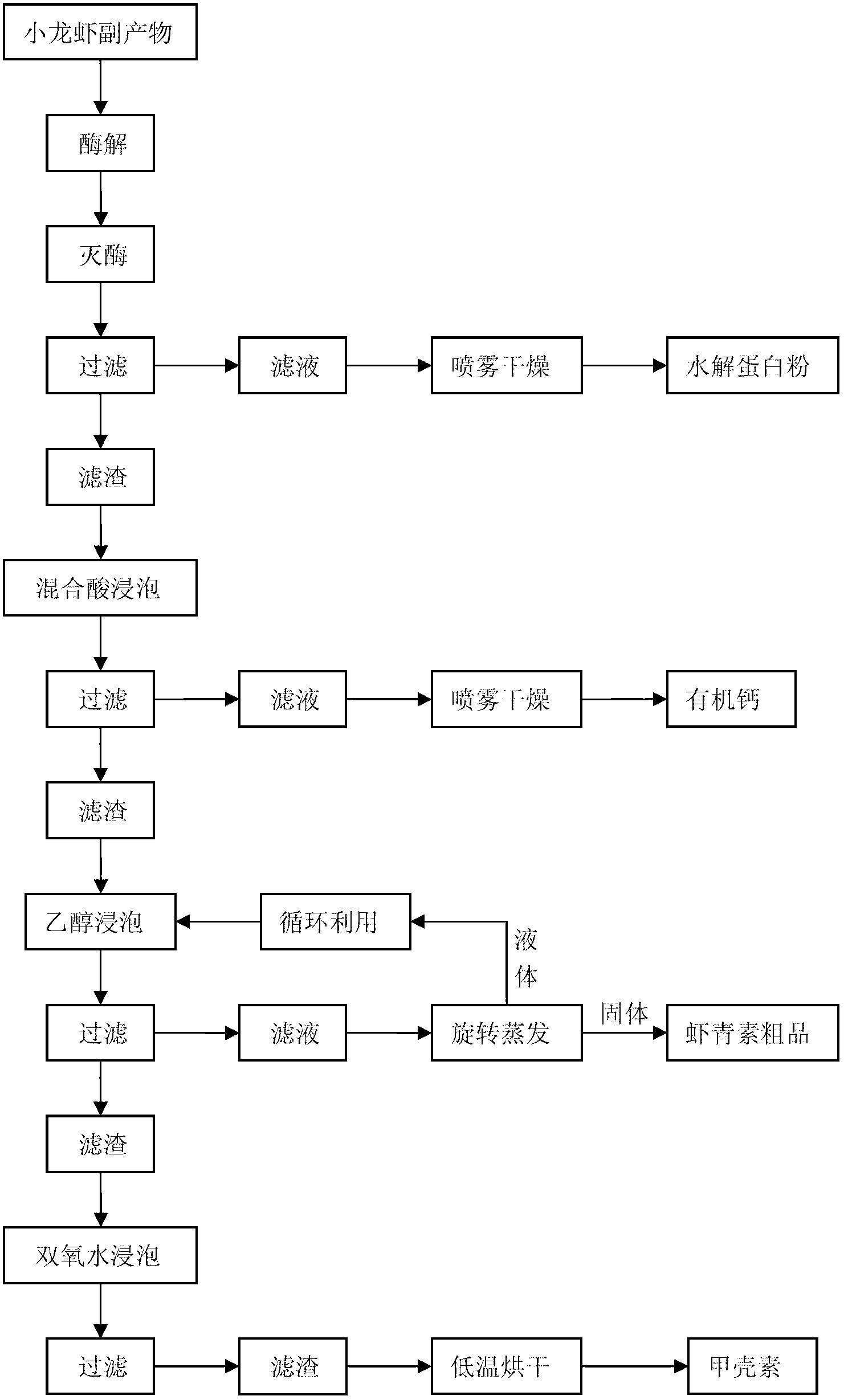

Image

Examples

Embodiment 1

[0031] Crush 100g of crayfish processing by-products to a particle size of 5-10mm with a tissue grinder, add 600mL of water, heat to 50°C, add alkaline protease according to the enzyme-to-substrate ratio of 2300u / g, shake and hydrolyze in a constant temperature water bath for 2.5h To obtain the enzymatic solution, cool in an ice-water bath for 0.5h to inactivate the enzyme, filter the filtrate and spray dry it to obtain a protein hydrolyzate, filter the solid and wash it with water until neutral, then add 400mL of water, heat to 30°C, and then add mixed acid (citric acid : The molar ratio of malic acid: lactic acid is 2:3:6), the total mass is 25g, shake at constant temperature for 2h, then filter, the filtrate is spray-dried to obtain organic calcium, the solid is washed with water until neutral, add 300mL ethanol, and ultrasonically extract for 10min , then vibrated at 30°C for 2.5 hours, filtered, and the filtrate was rotary evaporated to obtain crude astaxanthin. The ethano...

Embodiment 2

[0033] Crush 500g of crayfish processing by-products to a particle size of 5-10mm with a tissue grinder, add 3.8L of water, heat to 45°C, add alkaline protease according to the enzyme-to-substrate ratio of 2000u / g, shake and hydrolyze in a constant temperature water bath for 5 hours To obtain the enzymatic solution, cool in an ice-water bath for 0.5 h to inactivate the enzyme, filter the filtrate and spray dry it to obtain a protein hydrolyzate, filter the solid and wash it with water until neutral, then add 1.8L of water, heat to 40°C, and then add mixed acid (lemon Acid: malic acid: lactic acid molar ratio is 2:3:6), the total mass is 100g, shake at constant temperature for 6h, then filter, the filtrate is spray-dried to obtain organic calcium, the solid is washed to neutral, add 2.5 L ethanol, ultrasonic Extract for 15 minutes, shake at a constant temperature of 25°C for 4 hours, filter, and the filtrate is rotary evaporated to obtain crude astaxanthin. The ethanol after rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com