The preparation method of zirconium potassium perchlorate insensitive ignition powder

A technology of potassium perchlorate and ignition powder, which is applied in the direction of explosives, etc., can solve the problems of not being able to store for a long time, not adapting, not involving the specifications and states of raw materials, and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and preferred example the present invention will be described in further detail:

[0027] In the first step, zirconium (Zr) powder is mechanically ground, and its specific process parameters and procedures are:

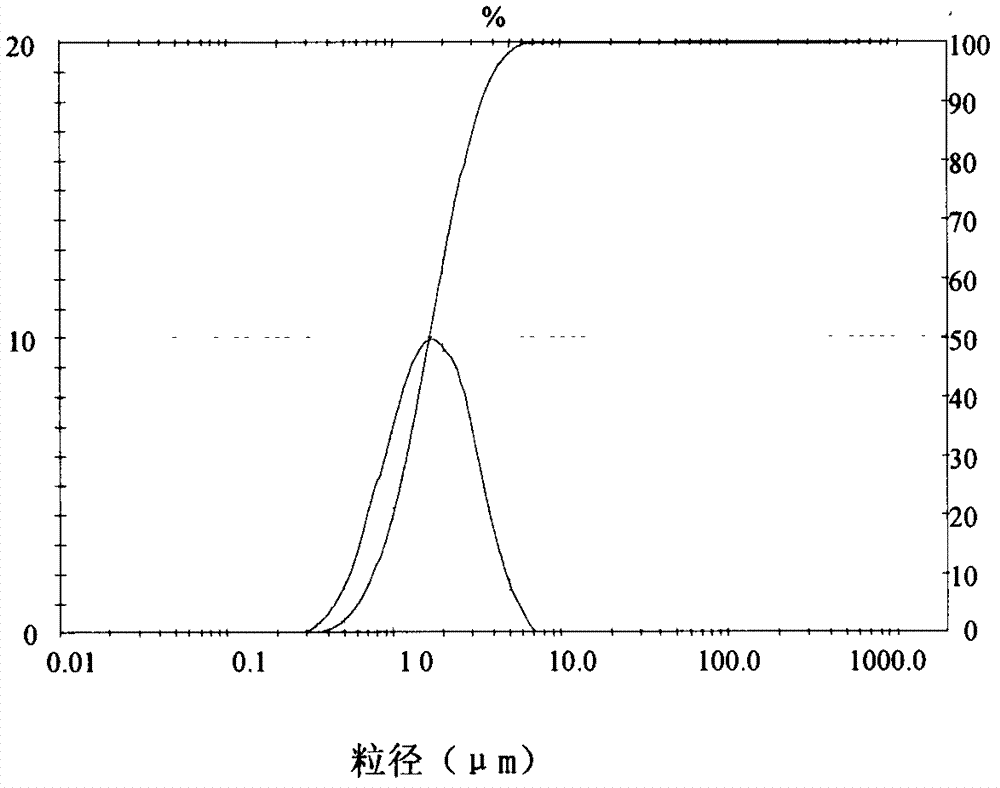

[0028] 1.1 The Japanese planetary ball mill PL-1200 is adopted, which mainly consists of a mechanical part and a control part. The mechanical part is mainly composed of a turntable with a diameter of 60cm, on which there are three symmetrical self-rotating ball mill jars (φ130×80mm) and fasteners. The ball milling tank is a flying saucer-shaped tank with a capacity of 500ml, which is divided into a cavity part and a sealing cover. The ball milling bead is a zirconia ball with a diameter of φ2mm. Pour 500g of ball milling beads, 30g of zirconium powder and 70ml of deionized water into the ball milling jars of the ball mill. Wrench to tighten the screw. Put the three ball mill jars into the fixed position of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com