Efficient water reducing agent for recycled aggregate concrete as well as preparation method and application thereof

A high-efficiency water-reducing agent and water-reducing agent technology, used in the field of building materials, can solve the problems of high water absorption, poor work performance, increased water consumption, etc., and achieve the effects of low strength, high water reduction, and reduced water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

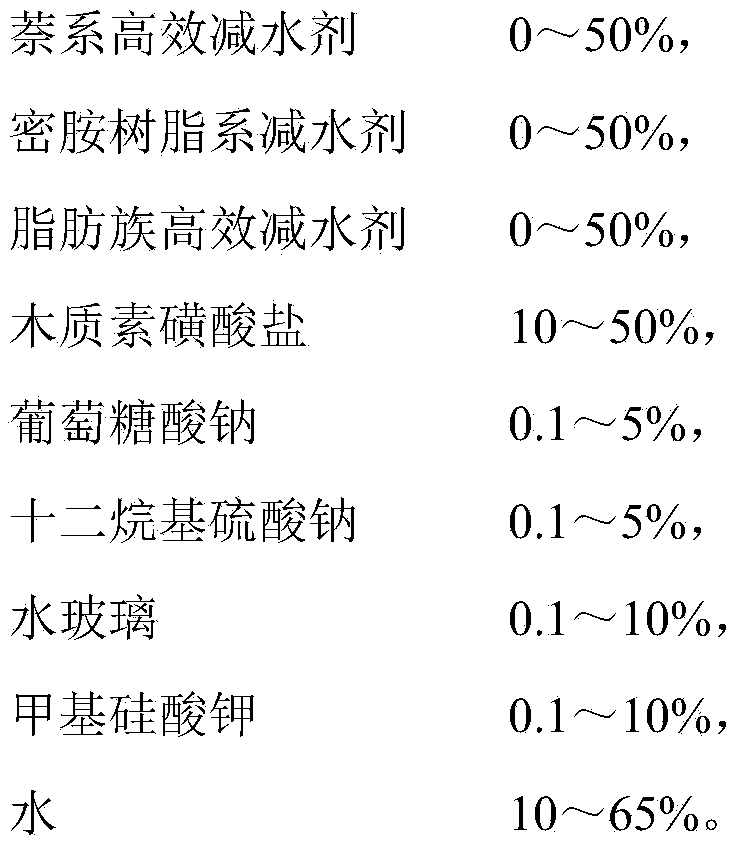

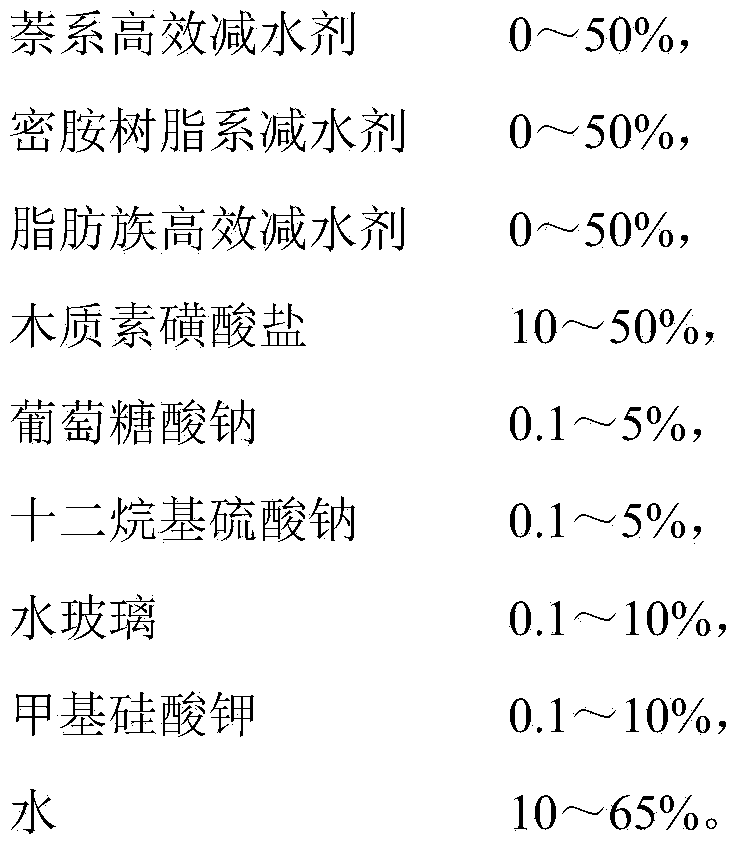

[0038] (1) Weigh the raw materials of each component according to the following proportions: 5% of β-naphthalene sulfonate formaldehyde condensate, 5% of sulfonated melamine formaldehyde resin, 10% of water-soluble sulfonated acetone-formaldehyde polycondensate, lignosulfonic acid Calcium 10%, sodium gluconate: 2%, sodium lauryl sulfate: 0.3%, water glass: 10%, potassium methyl silicate: 0.1%, water 57.6%;

[0039] (2) Mix the raw materials of the above components evenly: the stirring temperature is 40° C., the stirring speed is 120 rpm, and the stirring time is 10 minutes.

Embodiment 2

[0041] (1) Weigh the raw materials of each component according to the following proportions: 30% of β-naphthalenesulfonate formaldehyde condensate, 5% of sulfonated melamine formaldehyde resin, 10% of water-soluble sulfonated acetone-formaldehyde polycondensate, lignosulfonic acid Calcium 10%, sodium gluconate: 0.5%, sodium lauryl sulfate: 0.5%, water glass: 0.1%, potassium methyl silicate: 10%, water 33.9%;

[0042] (2) Mix the raw materials of the above components evenly: the stirring temperature is 20° C., the stirring speed is 1300 rpm, and the stirring time is 5 minutes.

Embodiment 3

[0044] (1) Weigh the raw materials of each component according to the following proportions: 50% of β-naphthalenesulfonate formaldehyde condensate, 20% of sulfonated melamine formaldehyde resin, 0% of water-soluble sulfonated acetone-formaldehyde condensation polymer, lignosulfonic acid Calcium 10%, sodium gluconate: 5%, sodium lauryl sulfate: 1%, water glass: 0.5%, potassium methyl silicate: 0.5%, water 13%;

[0045] (2) Mix the raw materials of the above components evenly: the stirring temperature is 70° C., the stirring speed is 500 rpm, and the stirring time is 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com