Method for manufacturing contact terminal, contact terminal manufacturing apparatus, and contact terminal

一种接触端子、接触部分的技术,应用在制造工具、接触部件、接触件制造等方向,能够解决增加制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

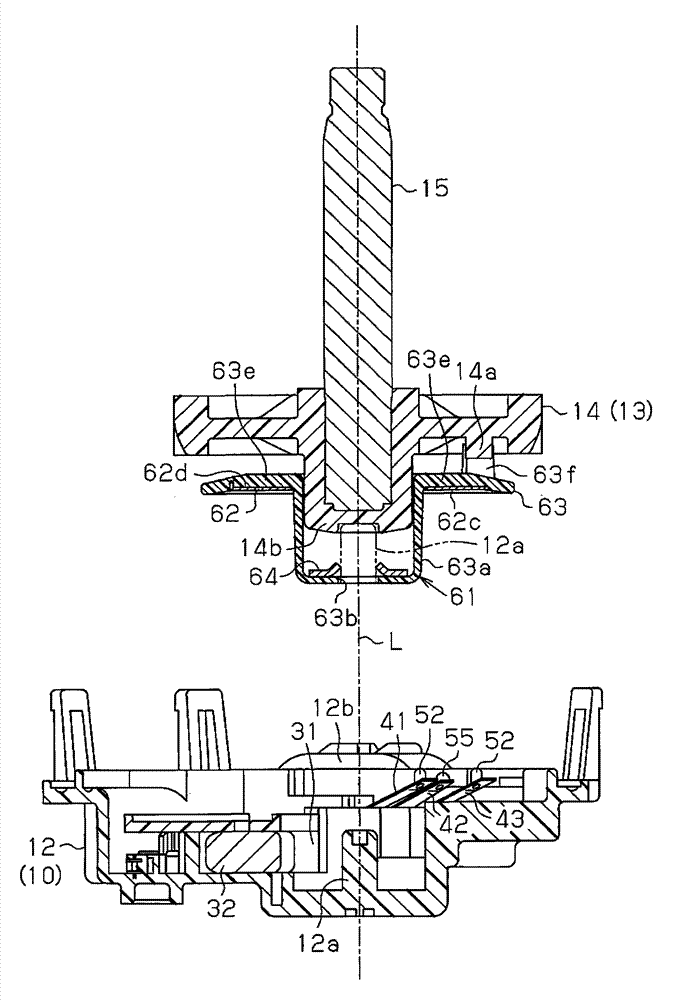

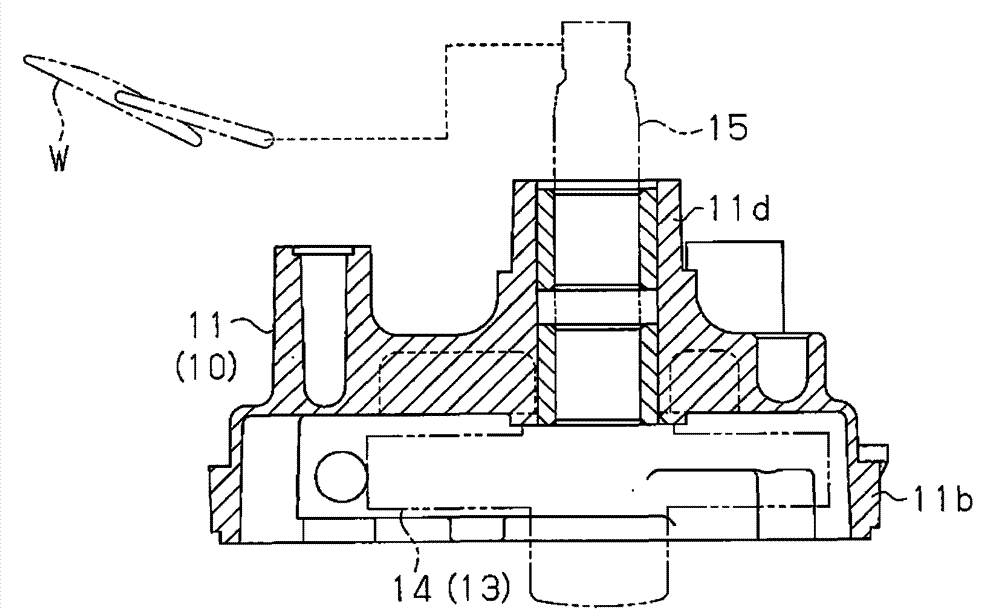

[0028] Referring to the accompanying drawings, an embodiment according to the present invention will be described below.

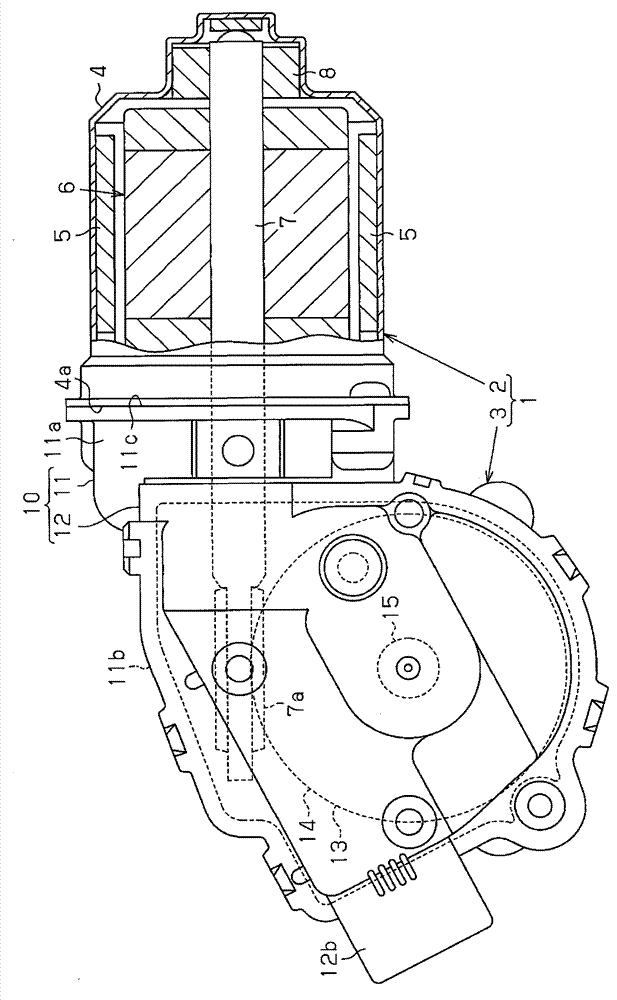

[0029] figure 1 It is a diagram of a motor 1 of this embodiment, which is used as a driving source of a car wiper device, and the car wiper device can wipe water such as raindrops from the windshield of a car. The motor 1 includes a motor unit 2 that generates rotation, and a reduction gear unit 3 that reduces the speed of rotation generated by the motor unit 2 and outputs the rotation.

[0030] The motor unit 2 includes a cylindrical yoke case 4 having a closed end and two pairs (four in total) of magnets 5 fixed to the inner peripheral surface of the yoke case 4 . Each pair of magnets 5 is opposite in the radial direction of the yoke housing 4 . A rotatable armature 6 is disposed inside the two pairs of magnets 5 . The armature 6 comprises a rod-shaped rotating shaft 7 having a base supported by a bearing 8 provided in the yoke housing 4 in the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com