Car shifter

A car gear shifting and assembly technology, which is applied to vehicle components, control devices, transportation and packaging, etc., can solve problems such as gaps, noise, and affecting shifting comfort, and achieve comfortable shifting and noise elimination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

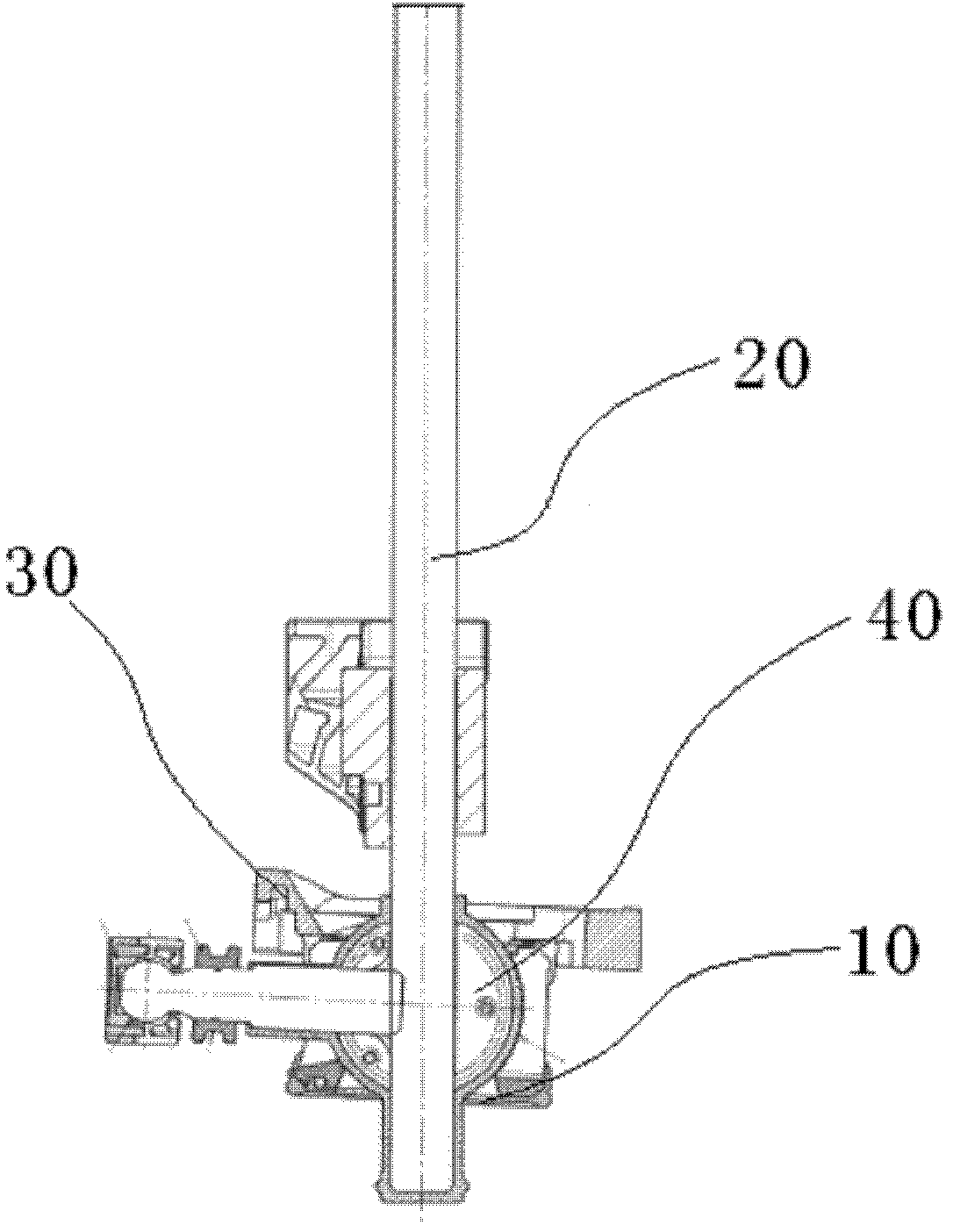

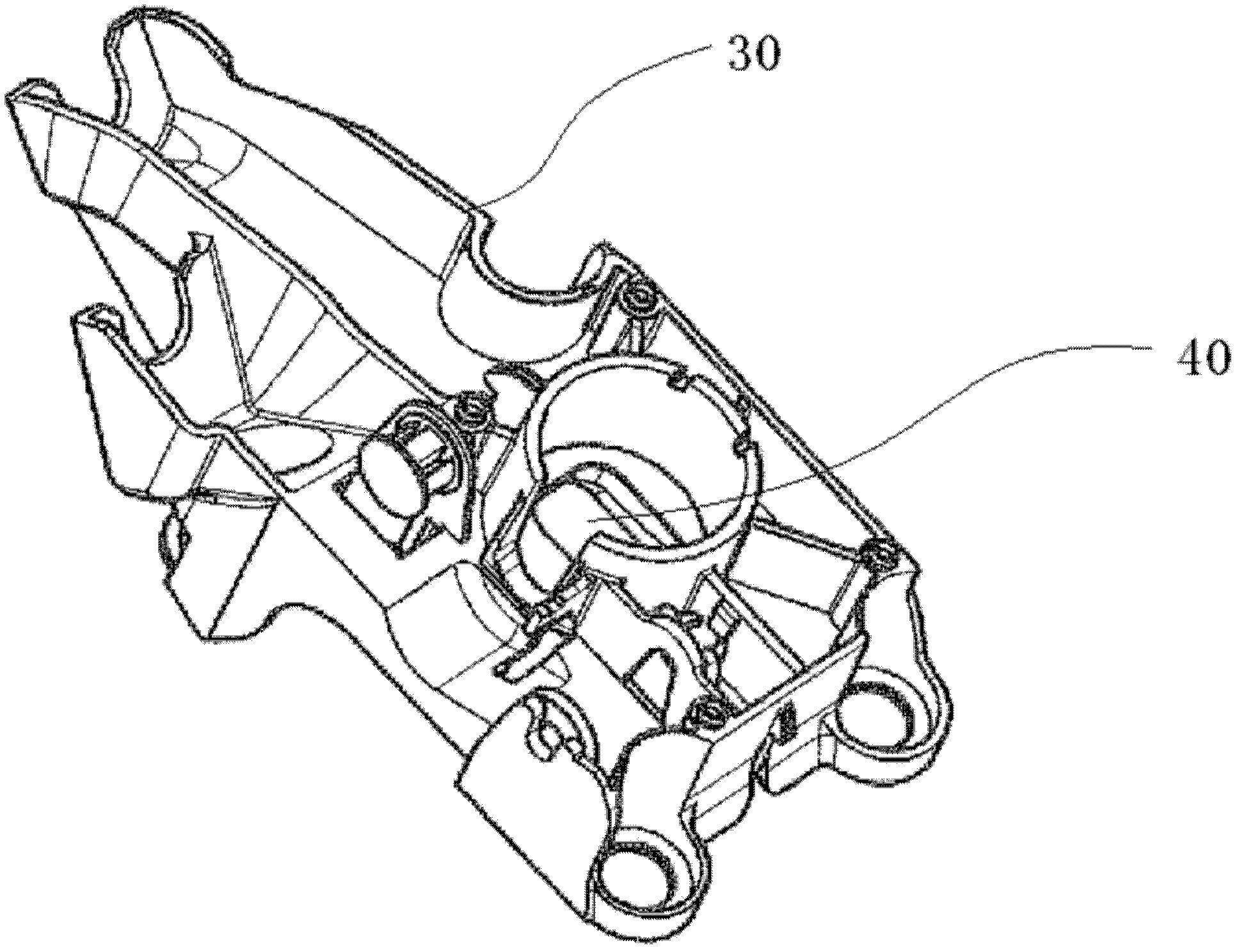

[0017] see figure 1 and figure 2 As shown, an automobile shifter of the present invention includes a joystick assembly 20, a base 30 and a base hole 40, the base hole 40 is arranged on the base 30, and one end of the joystick assembly 20 is placed in the base hole 40 , the end of the joystick assembly 20 placed in the base hole 40 is provided with a bushing pad 10 .

[0018] The liner protector 10 of the present invention is wrapped on one end of the joystick assembly 20, which can eliminate the gap between the joystick assembly 20 and the base hole 40, thereby making shifting more convenient.

[0019] In order to reduce the noise generated during gear shifting, the liner protector 10 of the present invention is made of soft material, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com