An engine intake pipe clamp

An air intake pipe and engine technology, applied in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of inability to effectively fix irregular items, manual manual clamping, etc., and achieve convenient adjustment of the horizontal position of the workpiece and convenient processing. Processing, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

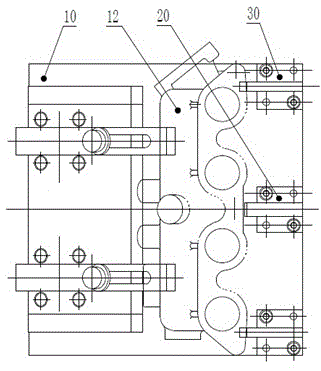

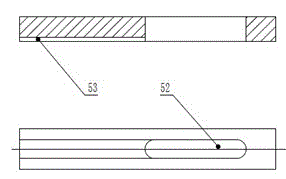

[0011] like figure 1 figure 2 As shown, the invention is composed of a clamp body 10, a positioning seat 20, a positioning block 30, a pressure cylinder 40, and a pressure plate 50. The bottom of the positioning block 30 is fixed on the clamp body 10 through a taper pin hole of a bolt, and the positioning seat 20 is fixed by threaded connection. At the midpoint of the two positioning blocks 30, the taper pin hole at the joint is used for assembly. Pressing plate 50 constitutes clamping device together with support rod 51, spring 54, pressure cylinder 40, and pressing plate 50 is connected on the panel 11 of clamping body 10 by supporting rod 51, spring 54, and panel 11 is with clamping body 10 bottom plate when processing as required. The included angle can be any angle from 0 to 90 degrees. A pair of pressure cylinders 30 are symmetrically distributed front and back under the panel 11 of the clamp body 10, and the push rod 41 passes through the hinged hole on the panel 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com