Cross-flow submerged membrane filter core

A submerged membrane and cross-flow technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as easy clogging and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below in conjunction with accompanying drawing.

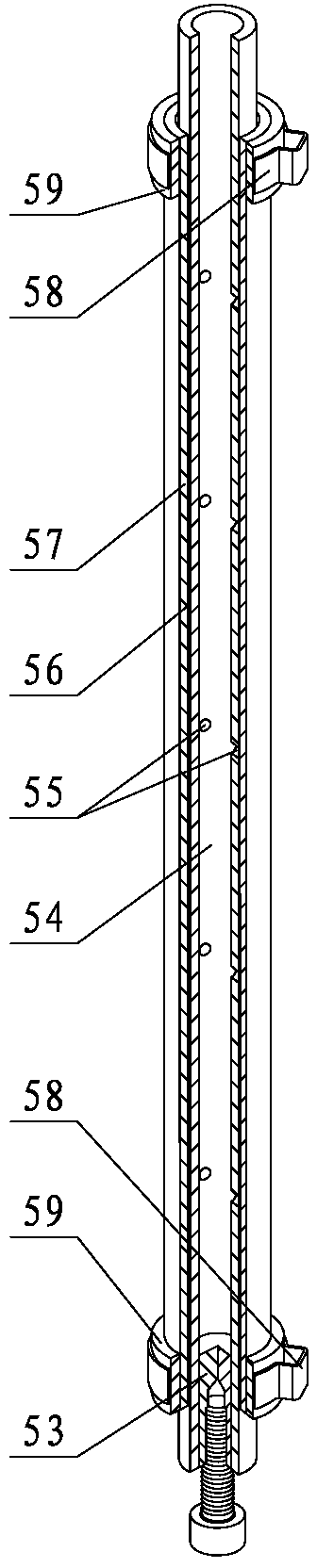

[0037] refer to figure 1 and figure 2 , The cross-flow submerged hollow fiber membrane filter element is composed of a connection sleeve 6, a fiber membrane installation handle 5, a fiber membrane component and a fiber membrane fixed end plate 1. The connecting sleeve 6 is installed on the outer surface of the upper end of the fiber membrane installation handle 5, the fiber membrane component is installed on the lower end of the fiber membrane installation handle 5, and the fiber membrane fixed end plate 1 is installed on the lower end of the fiber membrane component. The upper end of the fiber membrane installation handle 5 has a cross-flow interface 8, and the side surface of the connection sleeve 6 has a clear filtrate interface 7. The cross-flow submerged hollow fiber membrane filter element is fixed at a corresponding position through the installation hole 16 of the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com