Bio-concentration and product development of functional malt extract

A bio-enrichment and functional technology, applied in the extraction field of deep processing, can solve the problems of insignificant health care effect, incomplete amino acid, low peptide content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

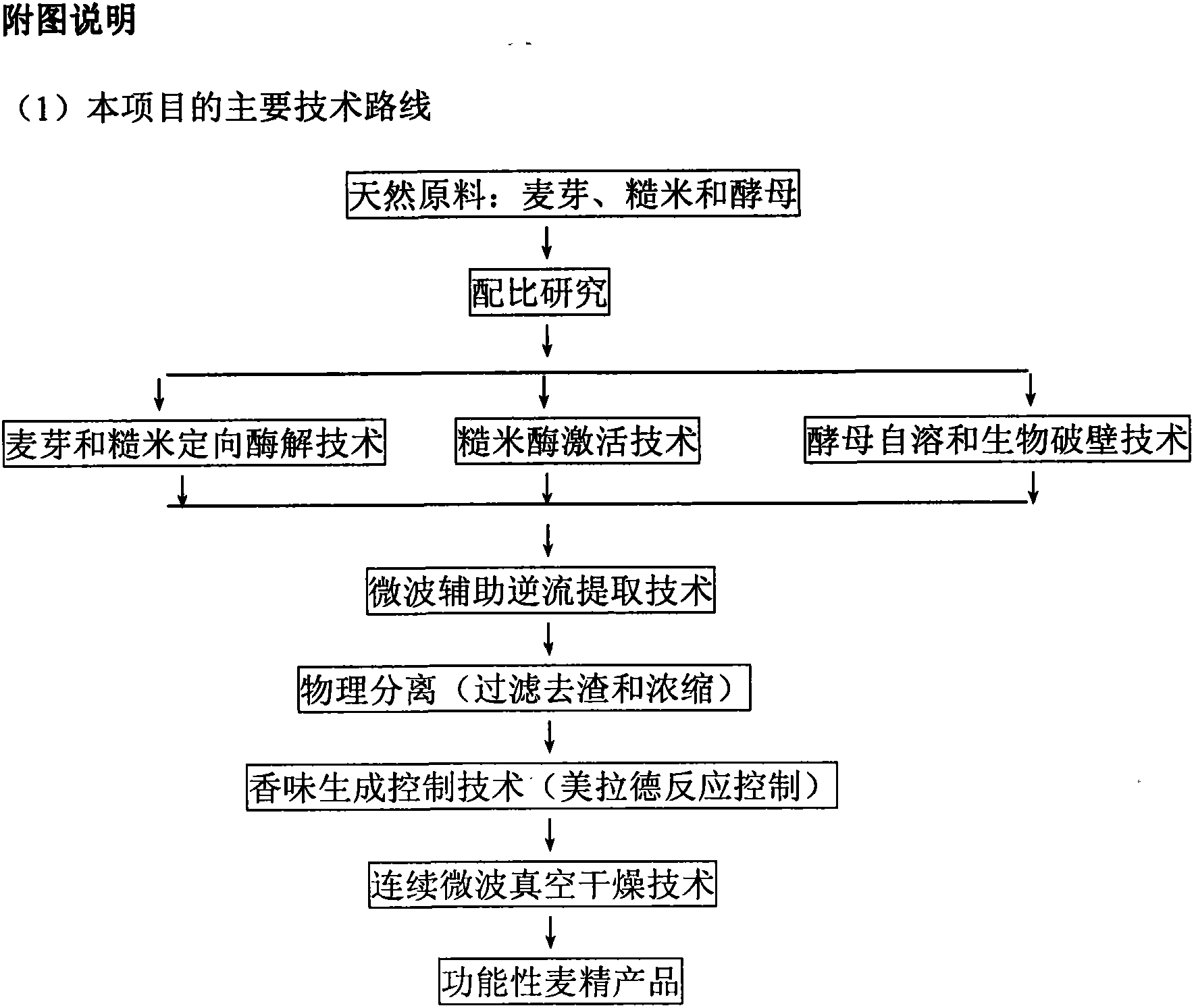

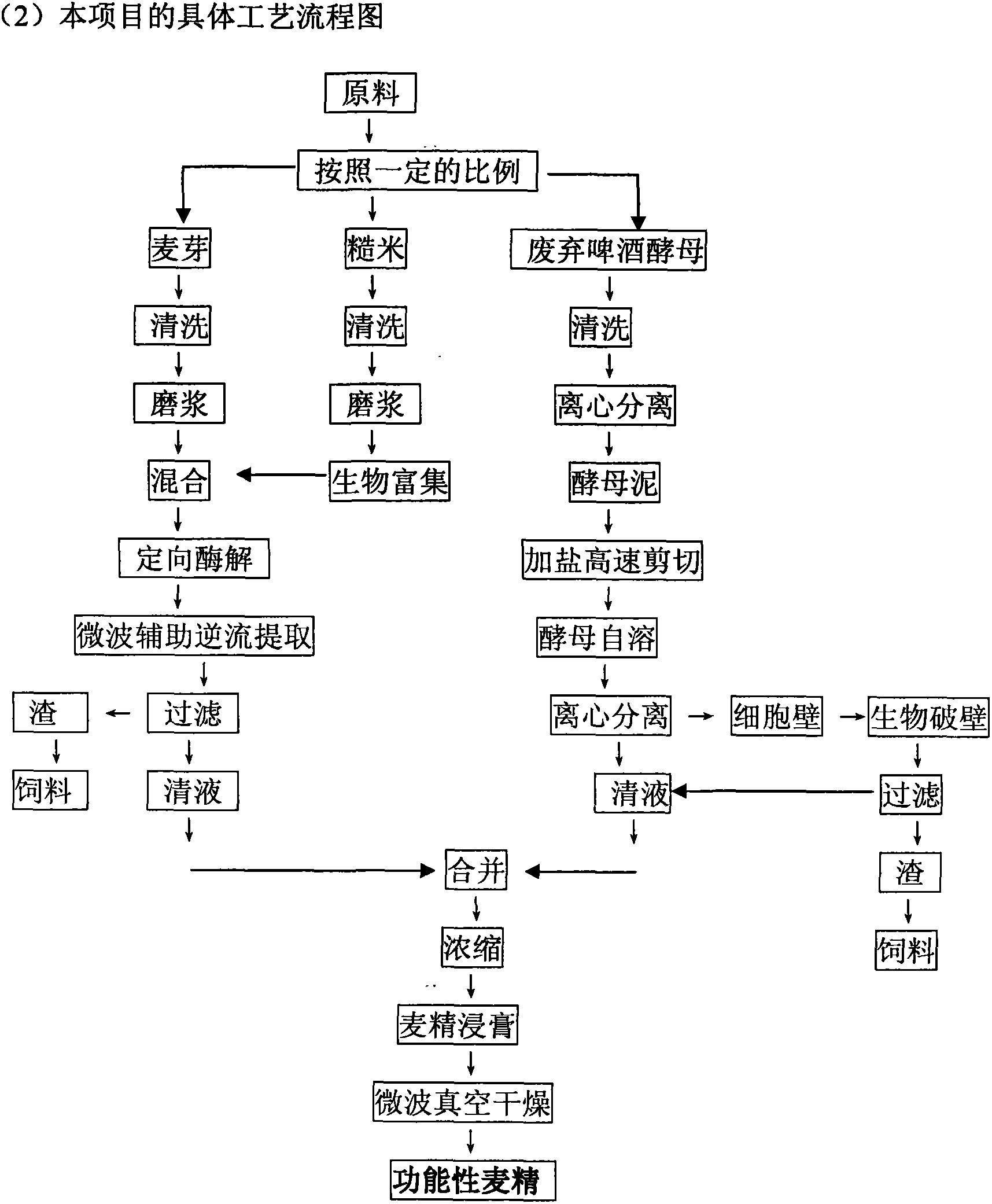

Method used

Image

Examples

Embodiment 1

[0031] A bioaccumulation and product development method of functional malt extract is characterized in that it consists of the following steps:

[0032] (1) Crushing of raw materials: barley malt and broken rice are pulverized with a universal pulverizer.

[0033] (2) Ingredients: Feed according to the ratio of malt, broken rice and yeast at a ratio of 1:1:1, and then add pure water to adjust the slurry.

[0034] (3) Enzymatic: Adding pyridoxal phosphate and Ca ions in a ratio of 0.1% can promote the activity of glutamic acid decarboxylase, and glutamic acid in brown rice is decarboxylated under the catalysis of glutamic acid decarboxylase to generate abundant γ -Aminobutyric acid, to achieve the purpose of enrichment.

[0035] (4) Enzymatic hydrolysis: Add α-amylase and protease at a ratio of 0.1% for directional biodegradation to obtain sugar sources and protein sources capable of producing good malt essence flavor. The feed solution is heated to 50° C. and kept for 1 hour....

Embodiment 2

[0043] A bioaccumulation and product development method of functional malt extract is characterized in that it consists of the following steps:

[0044] (1) Crushing of raw materials: barley malt and broken rice are pulverized with a universal pulverizer.

[0045] (2) Ingredients: Feed according to the ratio of 1:2:1 of malt, broken rice, and yeast, and then add pure water to adjust the slurry.

[0046] (3) Enzymatic: Adding pyridoxal phosphate and Ca ions in a ratio of 0.2% can promote the activity of glutamic acid decarboxylase, and glutamic acid in brown rice is decarboxylated under the catalysis of glutamic acid decarboxylase to generate abundant γ -Aminobutyric acid, to achieve the purpose of enrichment.

[0047] (4) Enzymatic hydrolysis: Add α-amylase and protease at a ratio of 0.3% for directional biodegradation to obtain sugar sources and protein sources capable of producing good malt essence flavor. The feed solution is heated to 60° C. and kept for 40 minutes.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com