Car Equipment

A technology for in-vehicle equipment and vehicles, applied in ticketing equipment, instruments, etc., can solve the problems of low sensitivity of anti-disassembly structure, affecting user experience, and malfunction of in-vehicle equipment, so as to avoid illegal disassembly and installation of in-vehicle equipment, and avoid mistakes. Action or illegal use, sensitivity-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

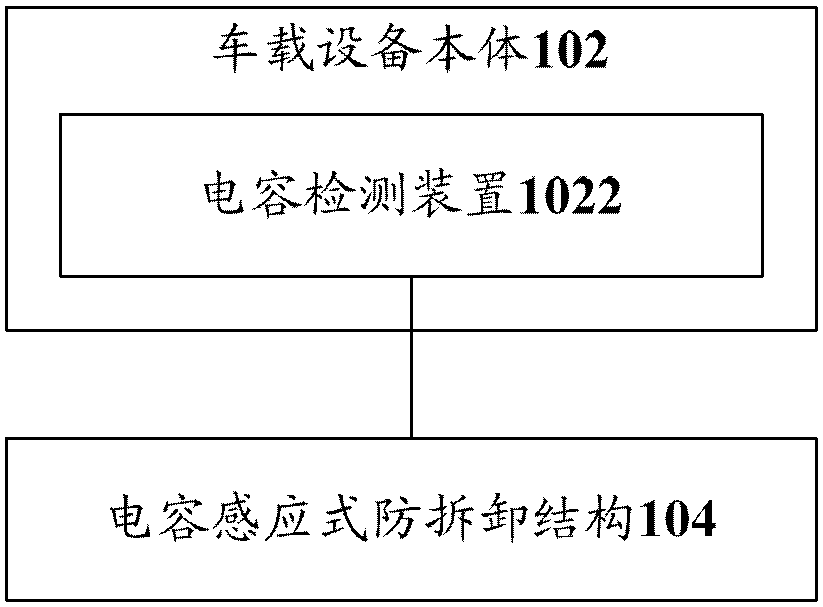

[0025] refer to figure 1 , shows a structural block diagram of a vehicle-mounted device according to Embodiment 1 of the present application.

[0026] The vehicle-mounted device in this embodiment includes a vehicle-mounted device body 102 and an anti-disassembly structure 104 .

[0027] Wherein, the anti-disassembly structure 104 includes a first electrode and a second electrode, and the first electrode and the second electrode form an equivalent capacitor, so that the anti-disassembly structure 104 becomes a capacitive induction type anti-disassembly structure. When the on-vehicle device is installed on the vehicle, the vehicle component to which the anti-disassembly structure 104 is bonded serves as the medium of the equivalent capacitor, and when it is not bonded, air can be used as the medium of the equivalent capacitor. When the medium between the first electrode and the second electrode changes, the capacitance between the first electrode and the second electrode chang...

Embodiment 2

[0032] The vehicle-mounted device in this embodiment includes a vehicle-mounted device body and a capacitive sensing anti-disassembly structure. In the following, the capacitive sensing type anti-disassembly structure will be introduced first.

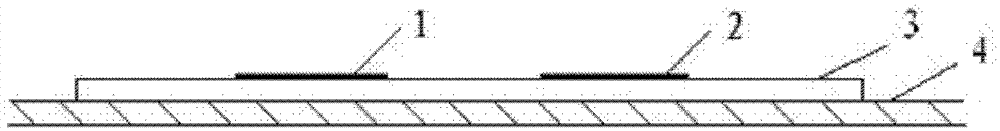

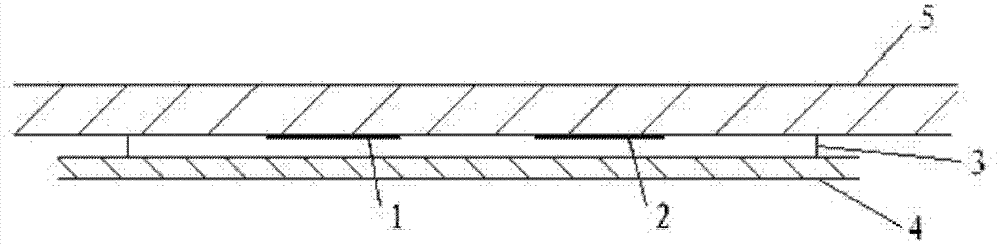

[0033] refer to figure 2 , shows a side view of a capacitive sensing disassembly-preventing structure of a vehicle-mounted device according to Embodiment 2 of the present application.

[0034] As shown in the figure, the first electrode 1 and the second electrode 2 of the capacitive sensing anti-disassembly structure form an equivalent capacitance, which is pasted on the shell 4 of the vehicle-mounted device body through an adhesive medium, in this embodiment, double-sided tape 3 . Moreover, after the equivalent capacitor is pasted, there is still sufficient space for pasting on the pasting medium, so that the equivalent capacitor, that is, the capacitive sensing anti-disassembly structure can be pasted on the vehicle component.

[0...

Embodiment 3

[0057] refer to Figure 5 , shows a schematic structural diagram of a vehicle-mounted device according to Embodiment 3 of the present application.

[0058] The vehicle-mounted device in this embodiment includes a capacitive sensing anti-disassembly structure 302 and a vehicle-mounted device body 304 .

[0059] Wherein, the capacitive sensing type anti-disassembly structure 302 includes a first electrode 3022 and a second electrode 3024, the first electrode 3022 and the second electrode 3024 can adopt the comb electrode in the second embodiment, and interleave according to the method in the second embodiment Arrangement, any other suitable electrodes can also be used and arranged accordingly. When the in-vehicle device is installed or removed, the capacitance between the first electrode 3022 and the second electrode 3024 changes.

[0060] The capacitive sensing anti-disassembly structure 302 is arranged on the outer side of the vehicle-mounted device body 304 by means of doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com