Measuring system for self-constriction of early-age concrete

A measurement system and concrete technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of high price of embedded strain gauges, inability to reuse, and late measurement age, so as to reduce human operation and The effect of recording errors, less consumables, and less environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

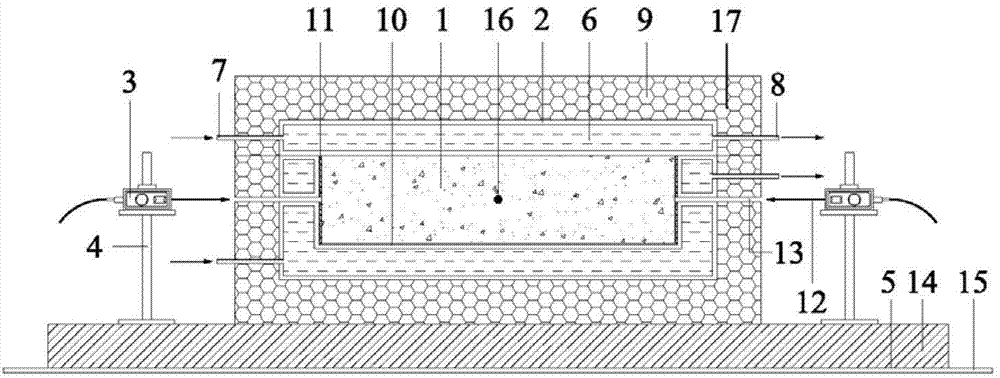

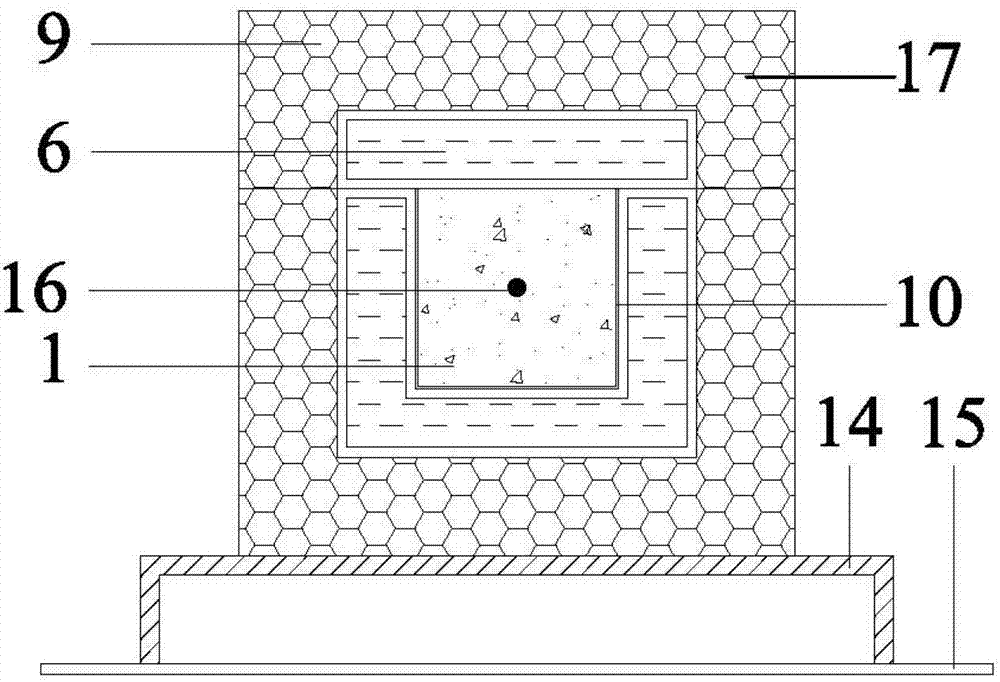

[0018] Example: such as figure 1 , 2 This method for measuring the autogenous shrinkage of concrete at an early age includes a concrete specimen 1, an intelligent curing box that controls the specimen at a constant temperature, a laser displacement meter 3 and a bracket 4, a base 5, a control computer and software. The outer surface of the concrete test piece 1 is completely sealed by a plastic film; the intelligent curing box 2 is a cavity structure, and the cavity is partially filled with a mixture of water and antifreeze 6, and the end is set to connect with an external cooling and heating system The water inlet 7 and the water outlet 8 are in a circulating state through a circulating pump; the intelligent curing box 2 is covered with a thermal insulation layer 9, and the inside is covered with Teflon plastic except for both ends. Sheet 10, with movable lightweight flexible lining plates 11 on both ends; the laser beam 12 of the laser displacement meter 3 is aligned with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com