Hydraulic filling type screw water-cooled cold water and heat pump unit

A heat pump unit, flooded technology, used in refrigerators, refrigeration components, compressors, etc., can solve the problems of short working life of oil seals of oil pumps, loss of refrigerant and oil leakage, high labor intensity, etc., to expand the application. range, increased reliability, and reduced maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

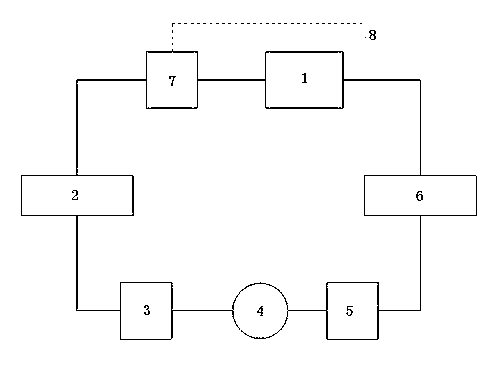

[0012] see figure 1 , The present invention includes a refrigeration system composed of a semi-hermetic screw compressor 1 with an oil separator, a condenser 2, a dry filter 3, a sight glass 4, an expansion valve 5 and an evaporator 6 connected in sequence. A pressure maintenance valve 7 is set between the compressor 1 and the condenser 2, the inlet of the pressure maintenance valve 7 is connected to the exhaust port of the compressor 1, the air inlet of the condenser 2 is connected to the outlet of the pressure maintenance valve 7, and the pressure maintenance valve 7 is balanced The port is connected to the low-pressure side of the compressor 1 through the balance pipe 8.

Embodiment 2

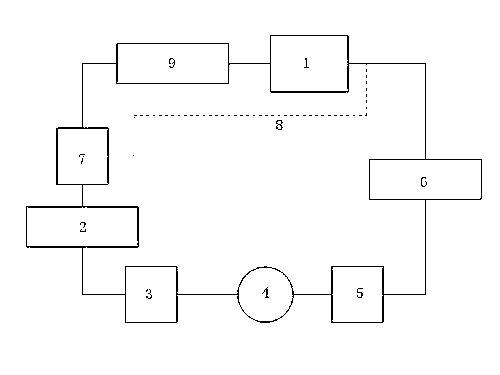

[0014] see figure 2 , The present invention includes a semi-hermetic screw compressor 1 without oil fraction, an oil separator 9, a condenser 2, a dry filter 3, a sight glass 4, an expansion valve 5 and an evaporator 6 connected in sequence. A pressure maintenance valve 7 is set between the oil separator 9 and the condenser 2, the inlet of the pressure maintenance valve 7 is connected with the exhaust port of the oil separator 9, the air inlet of the condenser 2 is connected with the outlet of the pressure maintenance valve 7, and the pressure maintenance The balance port of the valve 7 is connected with the low pressure side of the compressor 1 through a balance pipe 8 .

[0015] When using the present invention, since a pressure maintaining valve is added between the compressor (primary oil separator) and the condenser, by adjusting the opening pressure of the pressure maintaining valve, the operating pressure difference of the unit can be guaranteed, so that the unit can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com