Hydraulic type water-surface power generating device

A power generation device and hydraulic technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of short effective working time, high manufacturing cost, and difficult utilization, and improve wave energy conversion efficiency and manufacturing cost. Low, long working time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

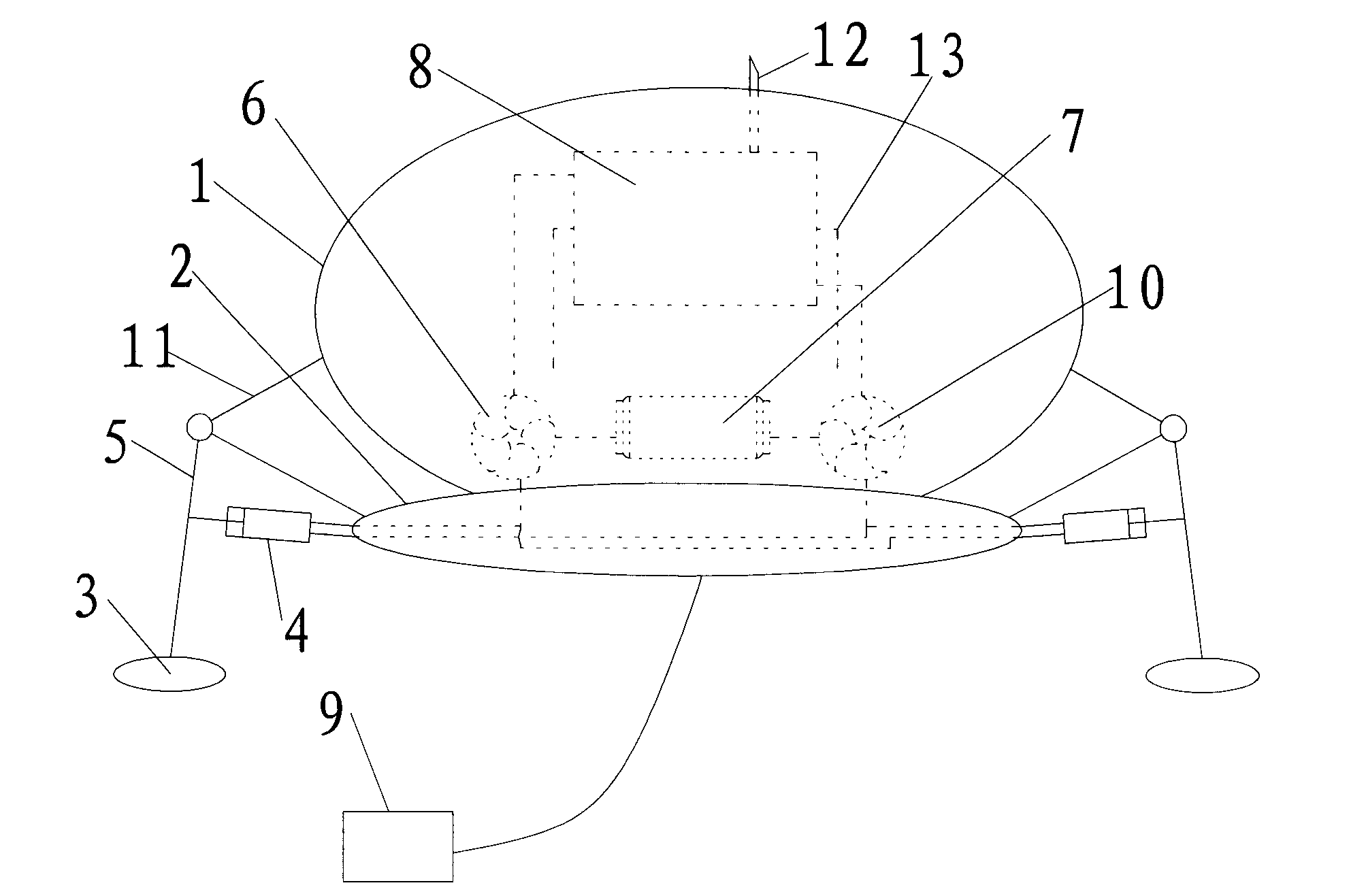

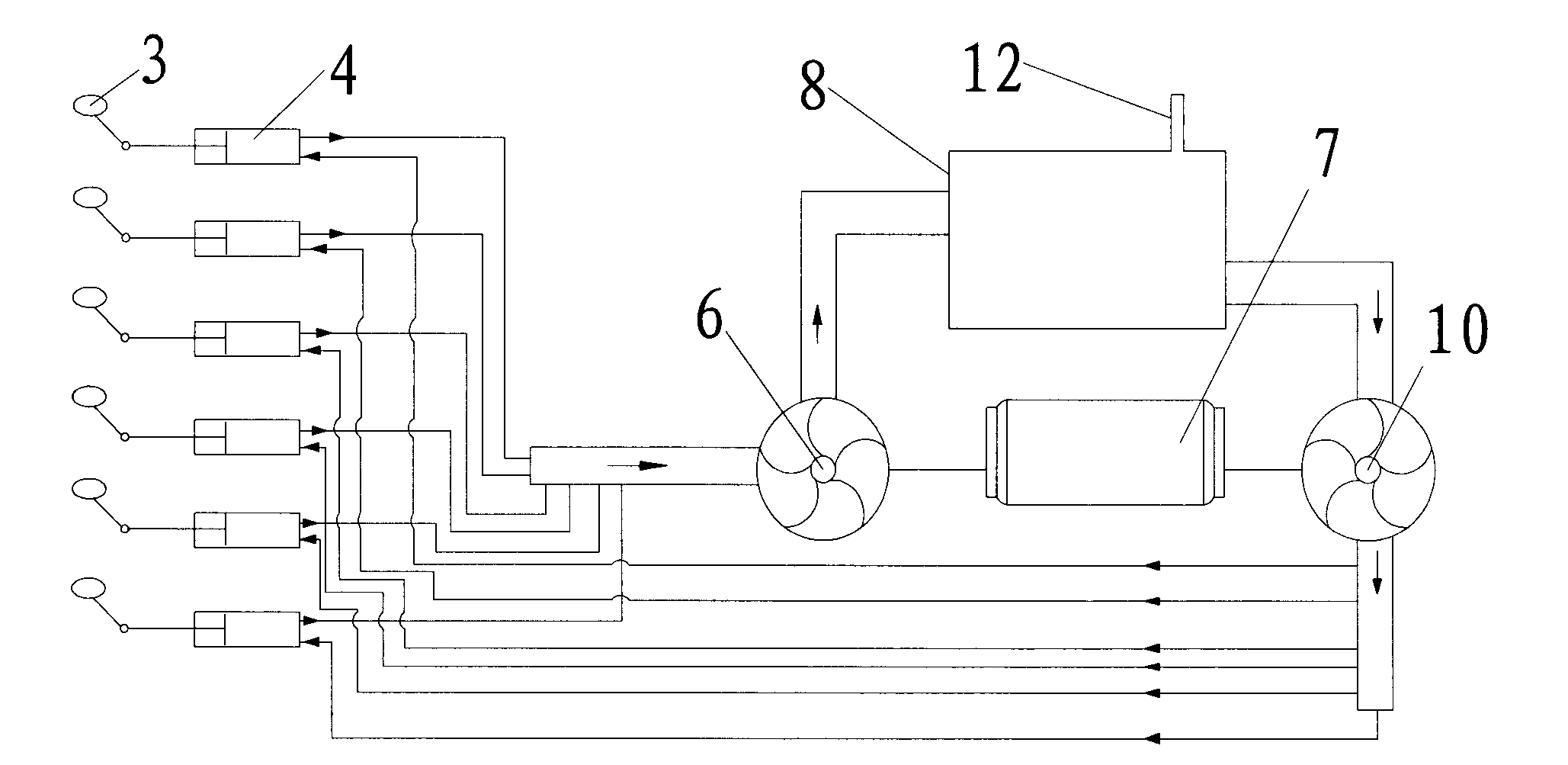

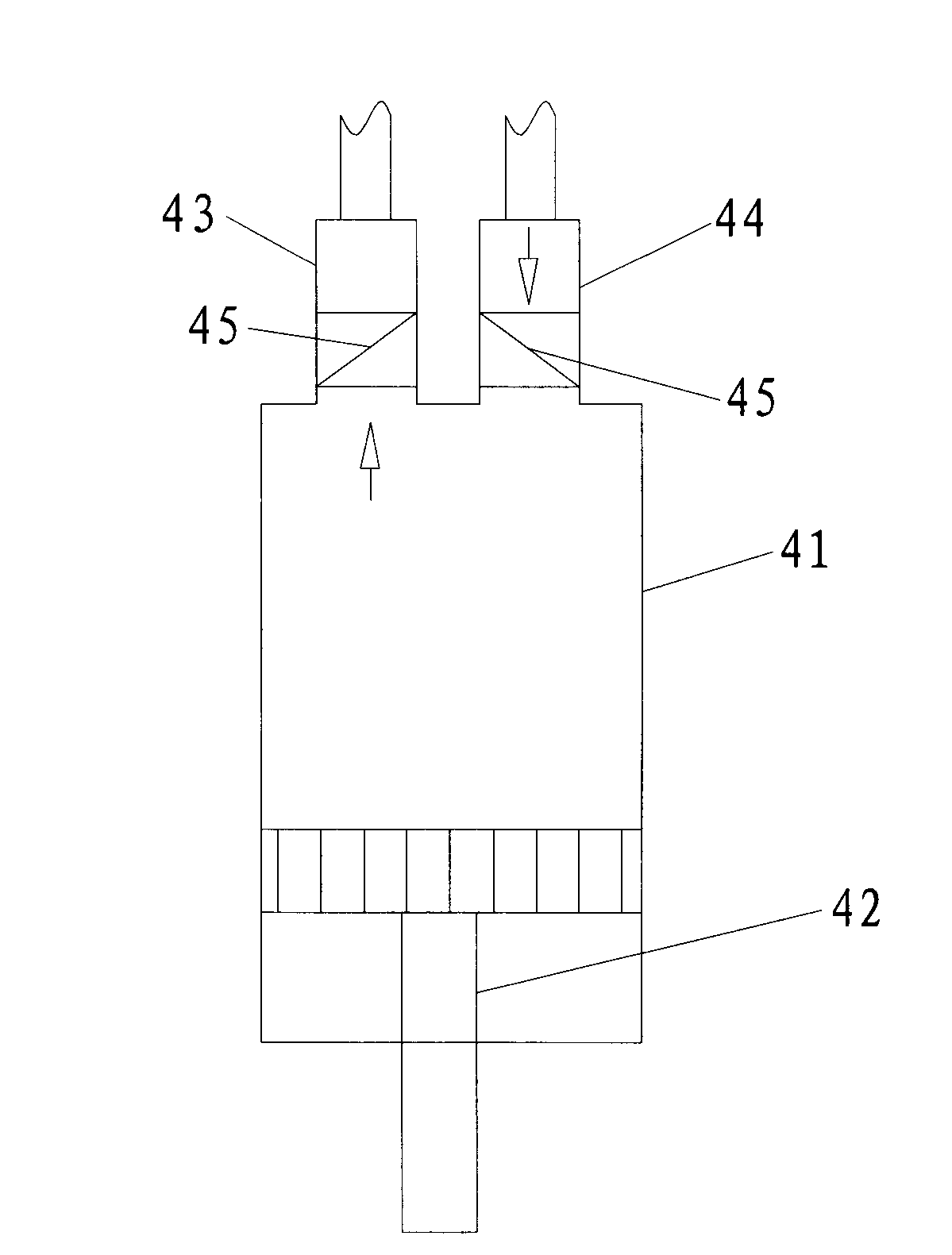

[0021] A hydraulic surface power generation device, mainly composed of a shell 1, a counterweight body 2 and several floating feet 3, the shell 1 is oval, and the water supply turbine 6, the return water turbine 10, the generator set 7 and the water tank are installed inside 8. The floating foot 3 is connected to the hydraulic pump 4 through the transmission rod 5. The hydraulic pump 4 is a plunger type hydraulic pump. One end of the hydraulic pump 4 is connected to the transmission rod 5 through a plunger 42. The plunger cylinder 41 at the other end of the hydraulic pump 4 is set The water outlet 43 and the water inlet 44, the water outlet 43 and the water inlet 44 are provided with a check valve 45 respectively, the water outlet 43 and the water inlet 44 of the hydraulic pump 4 are respectively connected to the upper water turbine 6 and the return water turbine 10 through pipelines, and the upper The water turbine 6 and the return water turbine 10 are connected to the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com