Casing Isolation Stratum Fracture Zone Method for Mine Underground Exploration and Release of High Pressure Karst Water Drilling Construction

A broken zone and karst water technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc., can solve the problems of buried drilling, stratum collapse, high cost, etc., to ensure long-term stability, delay construction period, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with specific embodiments.

[0013] The invention adopts the method of running multiple casings (key casings) and increasing the diameter of the opening orifice, which overcomes the problem of encountering stratum fracture zone when using underground roadway construction to detect high-pressure karst water.

[0014] Construction method and process:

[0015] 1. Determine the drilling structure

[0016] The specific technical solutions are as follows:

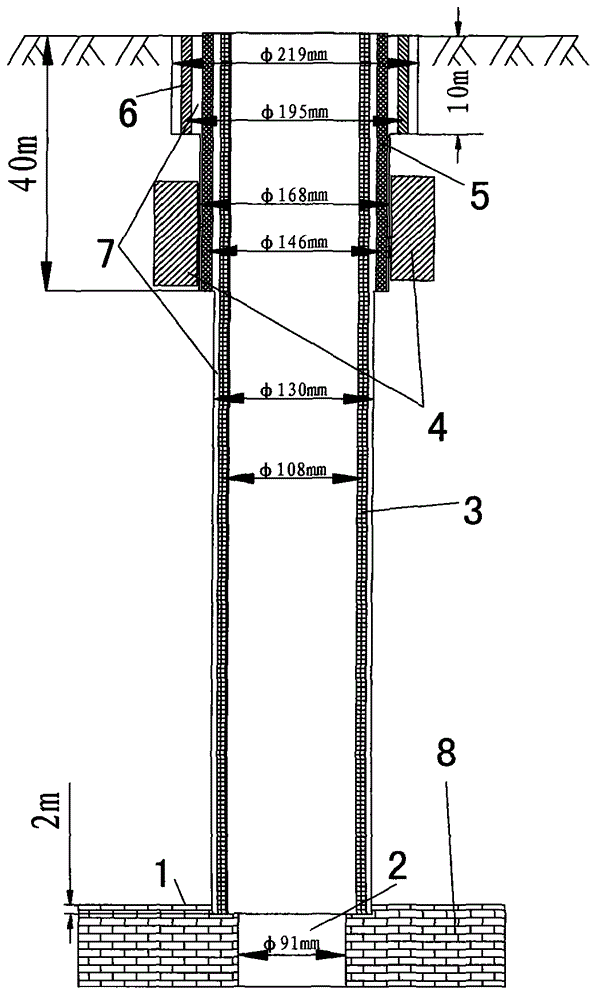

[0017] (1) Determine the aperture of the final pore aquifer (open pore 2), generally A( figure 1 The middle is φ91mm);

[0018] (2) Determine the diameter of the upper casing of the final hole aquifer, that is, the second casing 3 as B (larger than A, figure 1 The middle is φ108mm), and the drill diameter can be φ130mm;

[0019] (3) Determine that the diameter of the additional casing pipe 5 is C (larger than B, figure 1 The middle is φ146mm), and the drill diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com