Pressure relief method of coal bed high-pressure waterpower bedding drilling and cutting

A hydraulic and high-pressure technology, applied in drilling equipment and methods, drilling equipment, earth-moving drilling, etc., can solve the problem that it cannot fundamentally guarantee the safe production of coal mines, reduce the strength and damage of pressure, and can not effectively reduce the number of times of pressure. and other problems, to achieve the effect of overall pressure relief, reduce the pressure strength and damage degree, transfer and reduce the local stress of the coal body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

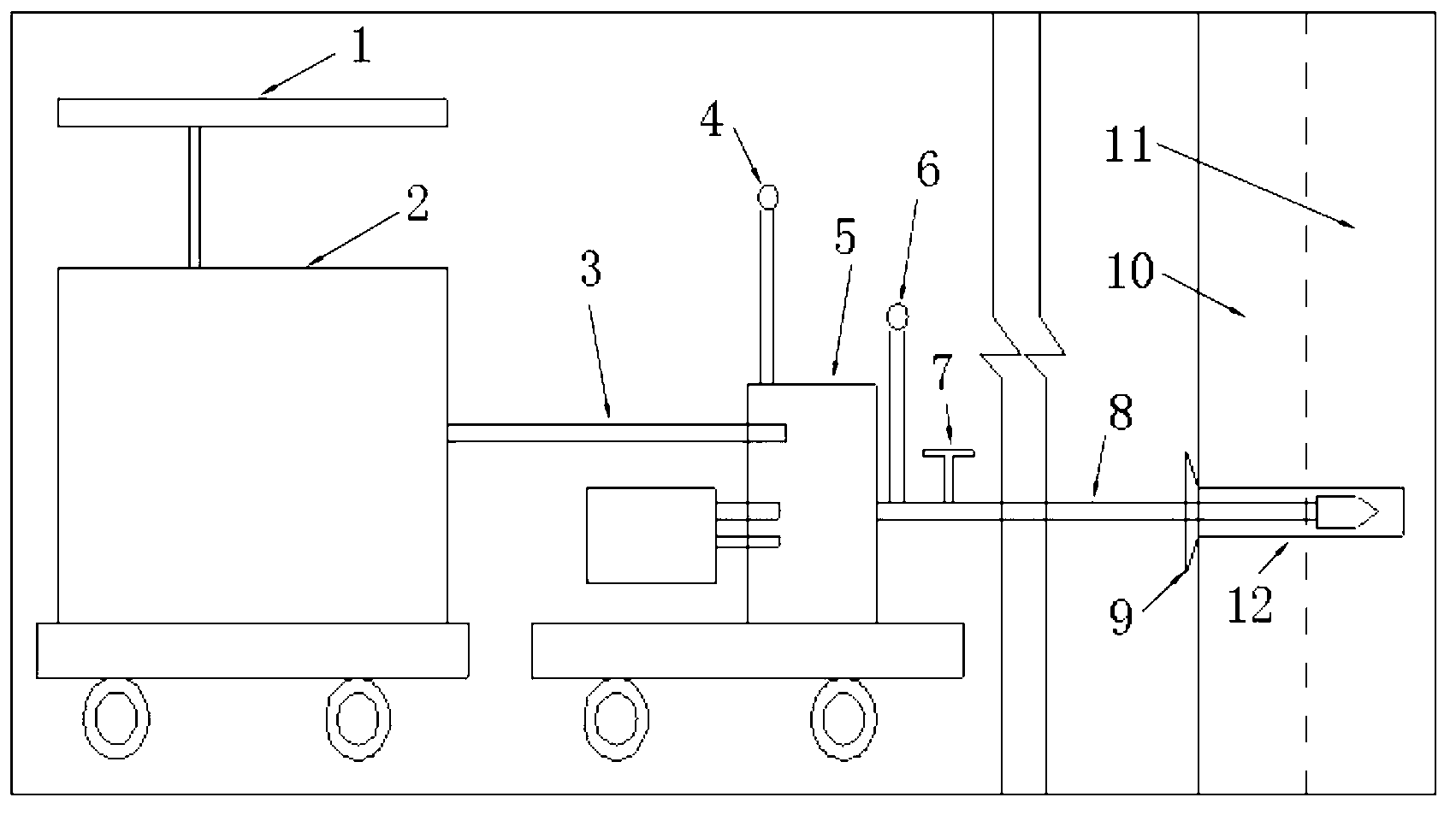

[0030] Such as figure 1 As shown, the equipment and technology of the present embodiment are respectively as follows:

[0031] 1) Equipment

[0032] Slit pump: model BRW400 / 31.5 coal mine emulsion pump, rated pressure 31.5Mpa, rated flow 400L / min;

[0033] Water tank: iron, volume 3m 3 ;

[0034] Pressure gauge: model YHY60 (B) mine intrinsically safe digital pressure gauge.

[0035] 2) pipeline

[0036] High-pressure pipeline: select high-pressure hoses with inner diameters of Φ32mm and Φ19mm and a compressive strength of not less than 35MPa.

[0037] 3) Drilling tools

[0038] Drilling rig: ZYJ-680 ground climbing hydraulic drilling rig, drill pipe Φ50mm, drill bit Φ94mm, used for the construction of drilling 12 holes, and the aperture standard of the upper three holes is 2.0㎜, 2.5㎜, 3.0㎜.

[0039] 4) Process flow

[0040] Water pipe 1→water tank 2→connecting pipe 3→water injection pump 5 (measured by pressure gauge 4)→high pressure pipeline 8 (measured by water mete...

Embodiment 2

[0043] The equipment and process of this embodiment are the same as those in Embodiment 1.

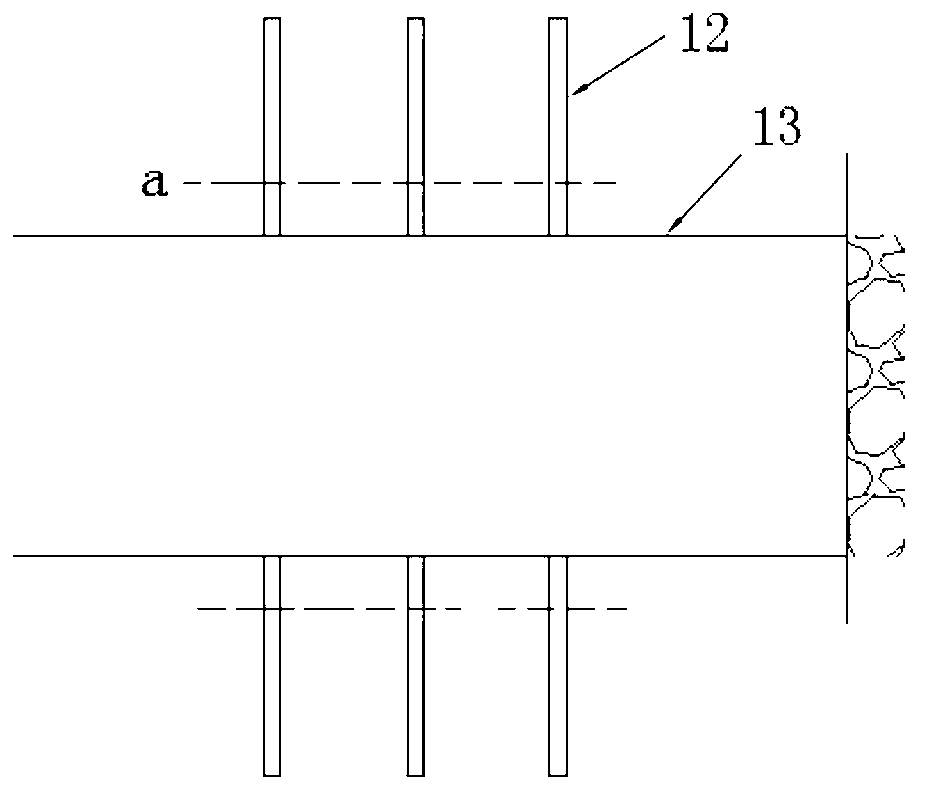

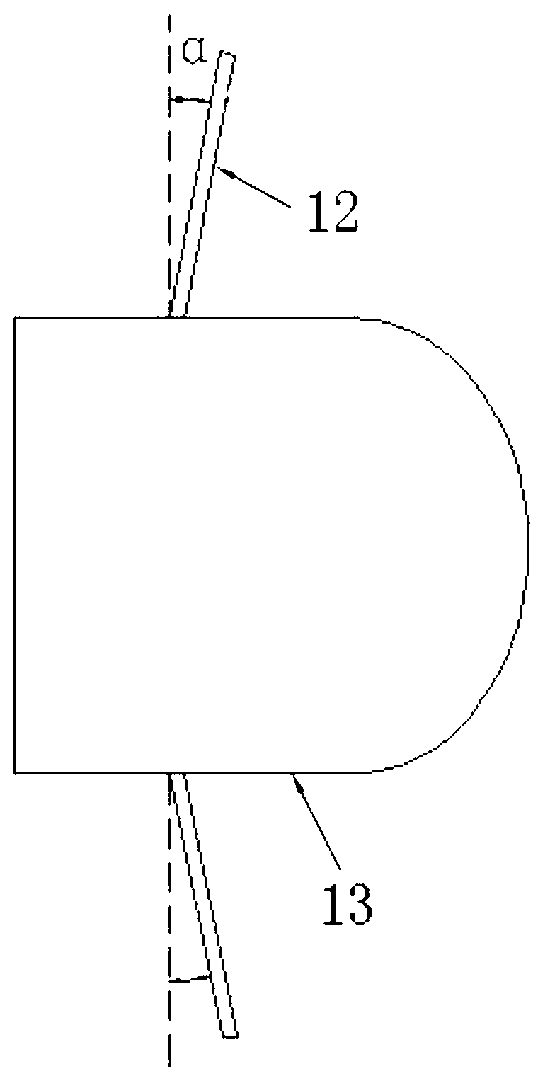

[0044] Such as Figure 5 As shown, within the range of 8 to 15m from the orifice, the jet moves axially along the borehole 12, and first cuts a small section of coal uninterrupted radially to form the first disc-type pressure relief cavity 15, and then moves The slotted drill pipe is cut uninterruptedly to another small section to form the second disc-type pressure relief cavity 15. Repeat the above steps to make uninterrupted cutting of multiple small sections, and finally form several small sections of disc-type pressure relief cavity 15. The distance between two adjacent disc-type pressure relief cavities 15 is preferably 2-4m, preferably 2.5m, and the coal output of each disc-type pressure-relief cavity 15 is 0.15-0.3t, and the total coal output The amount is controlled at about 0.6-1.2t.

[0045]In order to achieve a better slotting effect, the present invention adopts a method...

Embodiment 3

[0047] The equipment and process of this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com