A manufacturing process of the bottom plate of the welding and assembly line fixture of the automobile production line

An automobile production line and manufacturing process technology, applied in the field of automobile production line welding, can solve the problems of high precision machining difficulty and low machining efficiency, and achieve the effect of clear requirements, avoiding troubles, and ensuring precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The processing method is described in further detail below through specific examples. The following examples are only descriptive, not limiting, and cannot limit the protection scope of the present invention with this.

[0021] A manufacturing process for the bottom plate of a welding line fixture for an automobile production line, the manufacturing process includes the following steps:

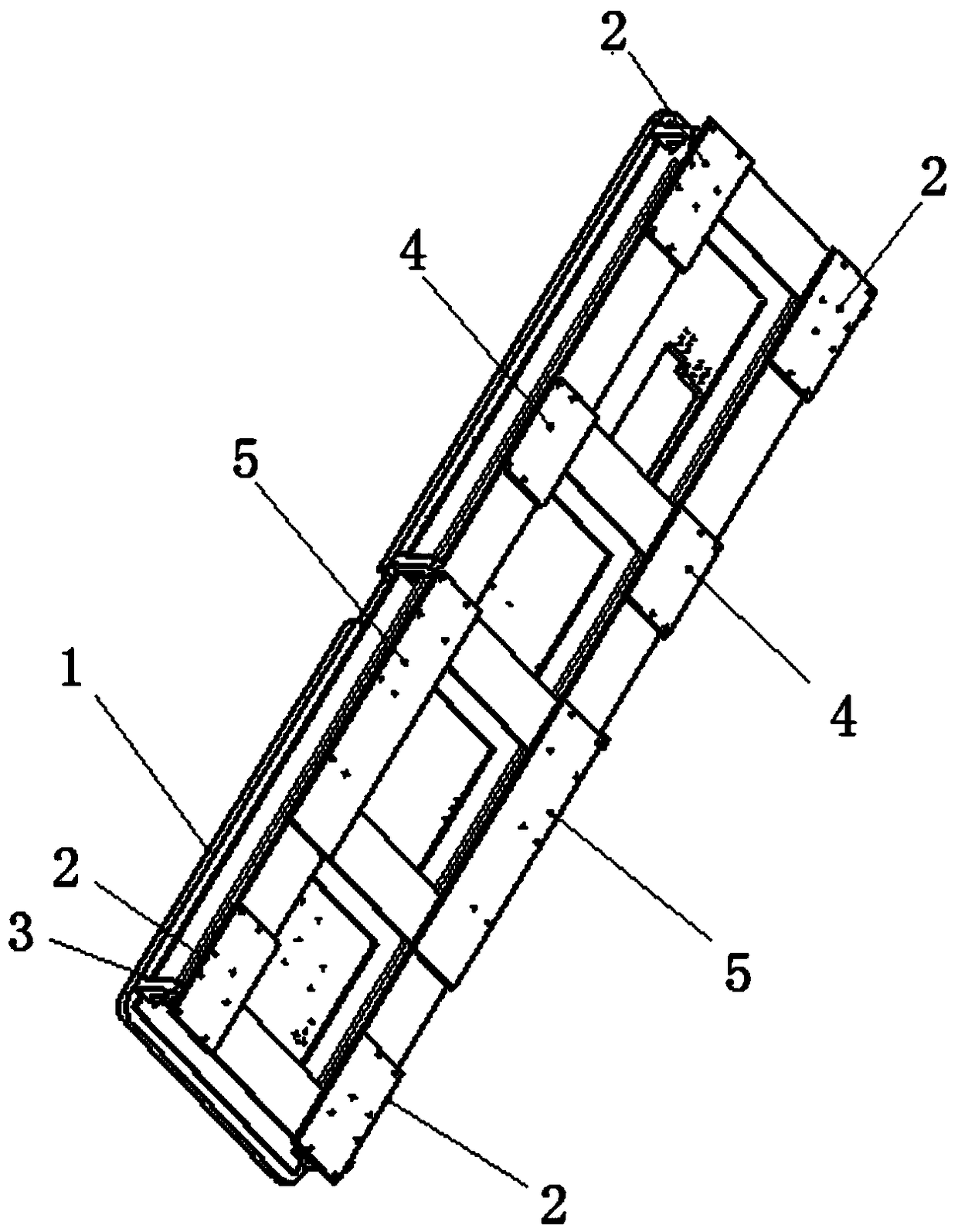

[0022] 1). Cutting the material and reserving the machining allowance: put the frame square tube 3, the upper fixture installation plate 1, the end guide wheel and the adjustment foot installation plate 2, the middle guide wheel and the adjustment foot installation plate 5, the middle adjustment foot installation plate 4 Install the drawing and cut the material separately, reserve 5mm machining allowance for the installation surface of the upper fixture installation plate, reserve the installation surface of the end guide wheel and adjustment foot installation plate, the middle guide wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com