Contact-type leveling device based on comparator

A comparator and contact-type technology, which is applied in the field of contact-type leveling devices based on comparators, can solve the problems of low detection accuracy, limited use conditions, narrow application range, etc., and achieve high detection accuracy, high work reliability, Achieving low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

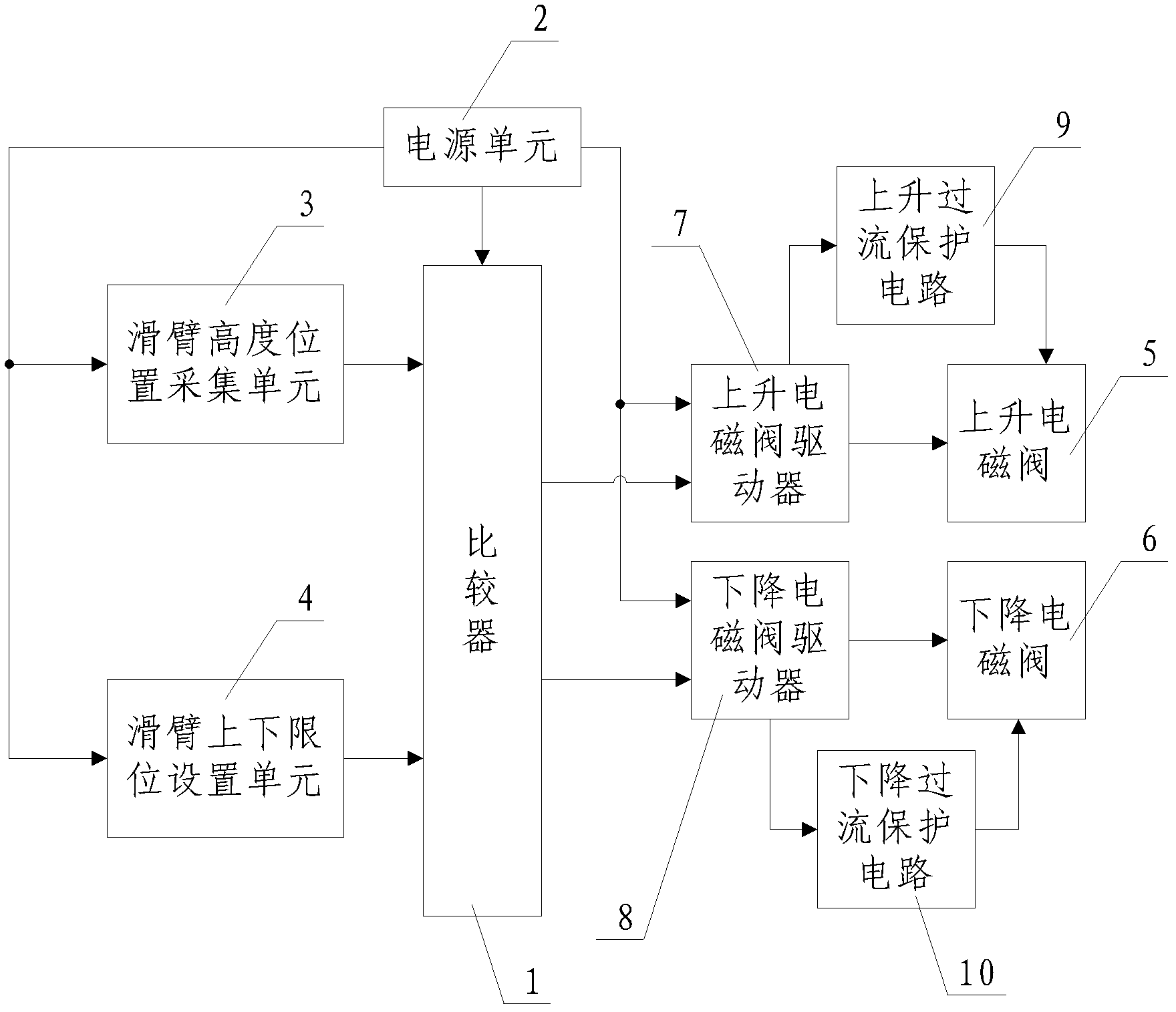

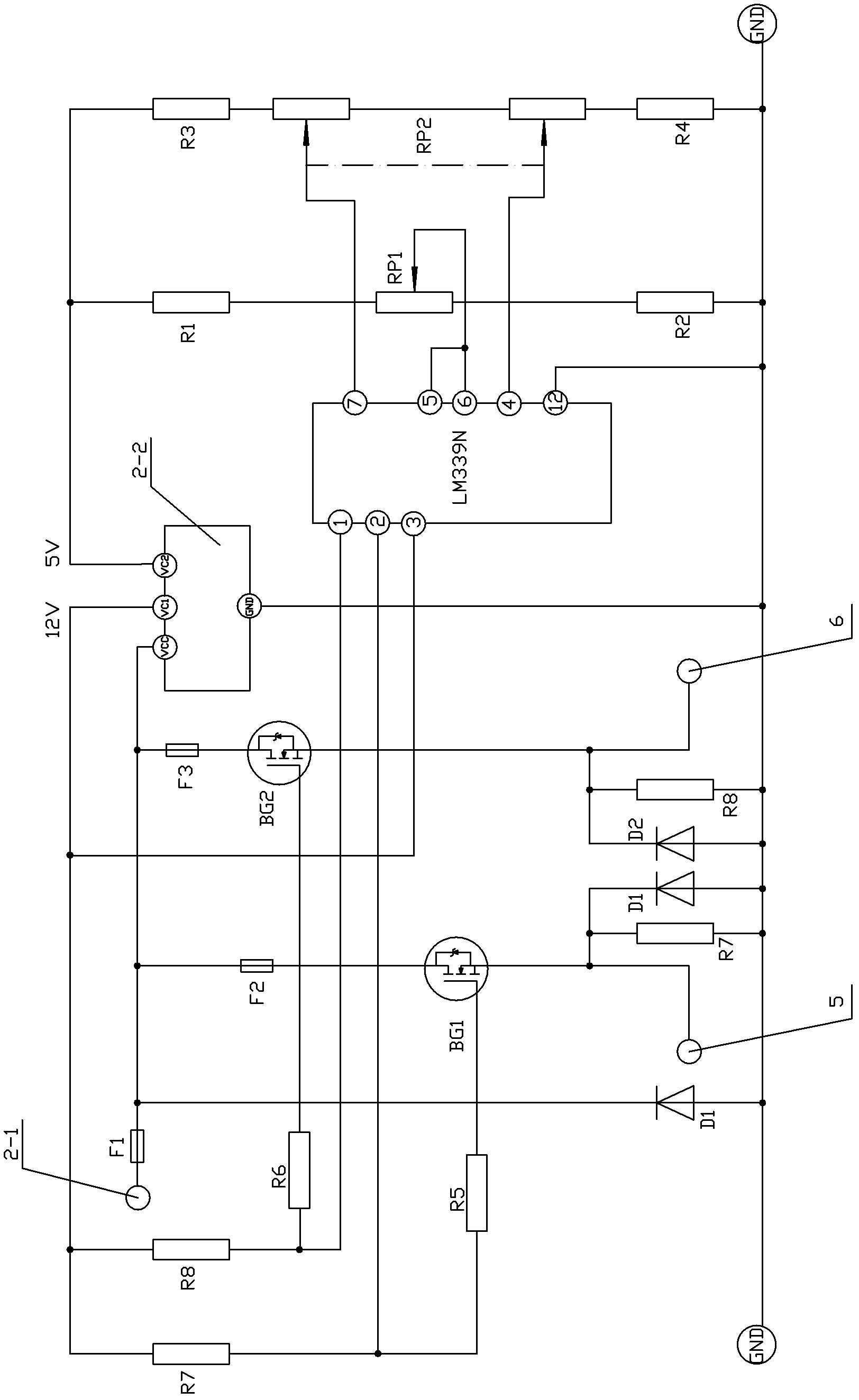

[0026] Such as figure 1 As shown, the present invention includes a comparator 1 and a power supply unit 2 for supplying power to each power consumption unit. The input terminal of the comparator 1 is connected with a sliding arm height position acquisition unit 3 for collecting the actual height position of the sliding arm and for setting The sliding arm height position acquisition unit 4 of the upper limit position and the lower limit position of the sliding arm height, the output terminal of the comparator 1 is connected with a control signal output unit for outputting a leveling control signal, and the control signal output unit includes a rising solenoid valve 5, The descending solenoid valve 6, the ascending solenoid valve driver 7 connected with the ascending solenoid valve 5 and the descending solenoid valve driver 8 connected with the descending solenoid valve 6, the ascending solenoid valve driver 6 and the descending solenoid valve driver 8 are all connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com