Fast-reaction acetylene generator

An acetylene generator and rapid reaction technology, which is applied in the acetylene generator, the parts of the acetylene gas generator, the petroleum industry, etc., can solve the problems of waste of water resources and long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

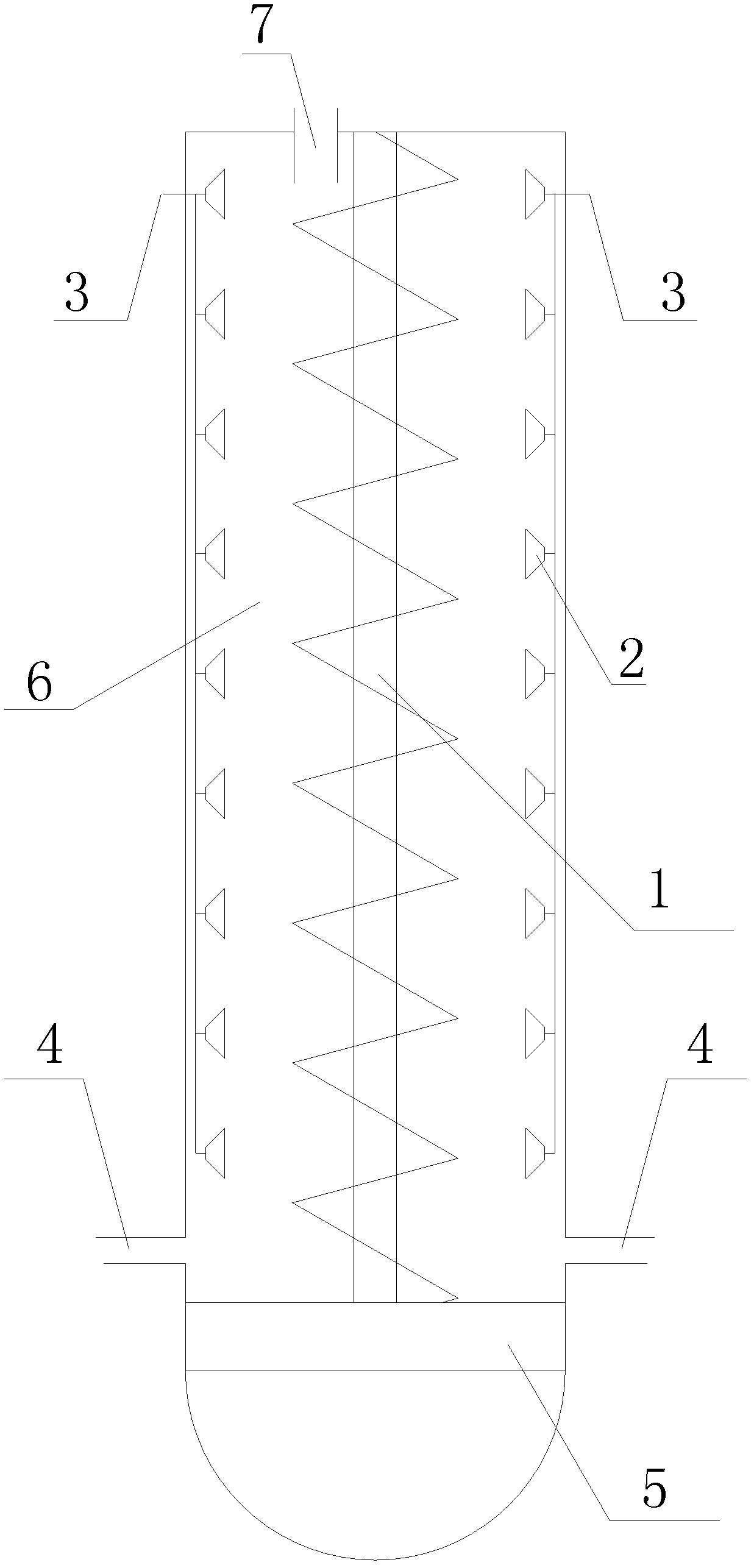

[0009] As shown in Figure 1, the present invention is a quick-response acetylene generator. The generator main body 6 is a vertical cylindrical shape. There is a vertical stirring shaft 1 inside the generator main body 6. A plurality of cloths are distributed on the inner wall of the generator main body 6. The water device 2 and the water distributor 2 are connected to the water inlet 3, the top of the generator main body 6 has an air hole 7, and the bottom side wall of the generator main body 6 has a calcium carbide feed port 4, and the calcium carbide feed port 4 is located above the roller 5, The roller 5 is arranged horizontally inside the generator main body 6 .

[0010] The working process of the present invention is to fill calcium carbide raw material from the calcium carbide feed port 4 at the bottom, and arrange it on the roller 5. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com