Light soft foamed sole material and preparation method thereof

A light and soft technology for sole materials, applied in the field of sole materials, can solve the problems of difficult control of foaming agents, influence on shoe size, uneven foaming, etc., and achieve the effects of reducing weight, saving materials and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

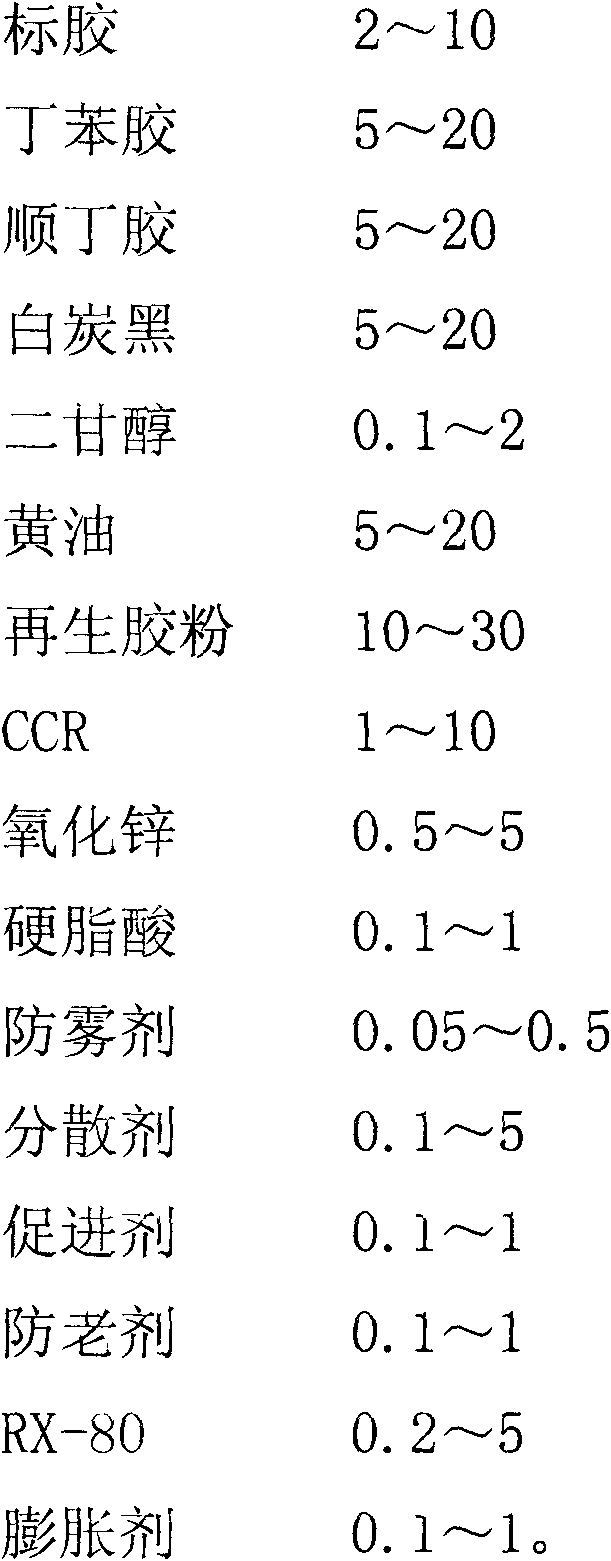

[0032] 1.1 Composition in parts by weight of light and soft foam sole material

[0033]

[0034]

[0035] 1.2 Preparation method

[0036] (1) Standard rubber, styrene-butadiene rubber, butadiene rubber, white carbon black, diethylene glycol, butter, reclaimed rubber powder, CCR, zinc oxide, stearic acid, anti-fogging agent, dispersant, accelerator, anti-aging agent , RX-80 and expansion agent are mixed and stirred evenly according to a certain weight part to obtain a mixture;

[0037] (2) Add the mixture to a banbury mixer, and banbury at 145° C. to 150° C. for 12 to 15 minutes to obtain a banbury mixture;

[0038] (3) Add the banburying mixture into the screw extruder, and carry out melt blending and granulation at 110°C to 150°C;

[0039] (4) Adding the granules to an open mill for mixing, then molding and foaming to obtain a light and soft foam sole material.

[0040] 1.3 Properties of light and soft foam sole materials

[0041] 1. Specific gravity

[0042] The s...

Embodiment 2

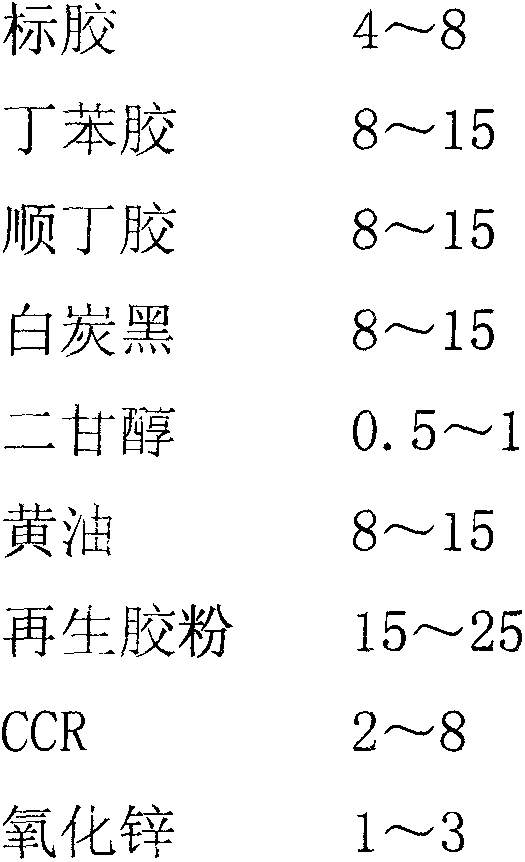

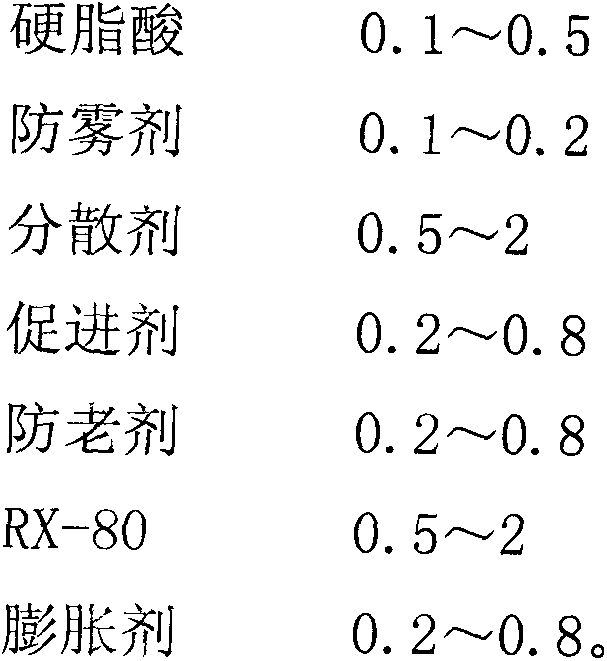

[0048] 2.1 Composition by weight of light and soft foam sole material

[0049]

[0050]

[0051] 2.2 Preparation method

[0052] The preparation method is the same as in Example 1.

[0053] 2.3 Properties of light and soft foam sole materials

[0054] 1. Specific gravity

[0055] The specific gravity of the light and soft foam sole material prepared by testing embodiment 2 is 0.72g / cm 3 , which is higher than the specific gravity of ordinary solid rubber (1.125g / cm 3 ) has been reduced a lot, and the weight is 36% lighter than the common solid rubber, so the light and soft foaming sole material prepared by the present invention can effectively reduce the sole weight.

[0056] 2. Folding resistance

[0057] According to the national standard G B / T3903.1-2008 "General Test Method for Folding Resistance of Footwear", the flexion angle is 50°±1°, the flexion frequency is (230±10) times / min, and the pre-cut opening is 5mm. Under the condition of (23±2)℃, continuous flex...

Embodiment 3

[0061] 3.1 Composition by weight of light and soft foam sole material

[0062]

[0063]

[0064] 3.2 Preparation method

[0065] The preparation method is the same as in Example 1.

[0066] 3.3 Properties of light and soft foam sole materials

[0067] 1. Specific gravity

[0068] The specific gravity of the light and soft foam sole material prepared by testing embodiment 3 is 0.68g / cm 3 , which is higher than the specific gravity of ordinary solid rubber (1.125g / cm 3 ) has been reduced a lot, and the weight is 39.6% lighter than common solid rubber, so it is illustrated that the light and soft foaming sole material prepared by the present invention can effectively reduce sole weight.

[0069] 2. Folding resistance

[0070] According to the national standard G B / T3903.1-2008 "General Test Method for Folding Resistance of Footwear", the flexion angle is 50°±1°, the flexion frequency is (230±10) times / min, and the pre-cut opening is 5mm. Under the condition of (23±2)℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com