Variable trailing edge wing driven by combination of shape memory alloy and piezoelectric fibrous composite material

A piezoelectric fiber and composite material technology, applied in the field of morphing wings, can solve the problems of slow response speed and small driving force, and achieve the effects of large deformation range, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

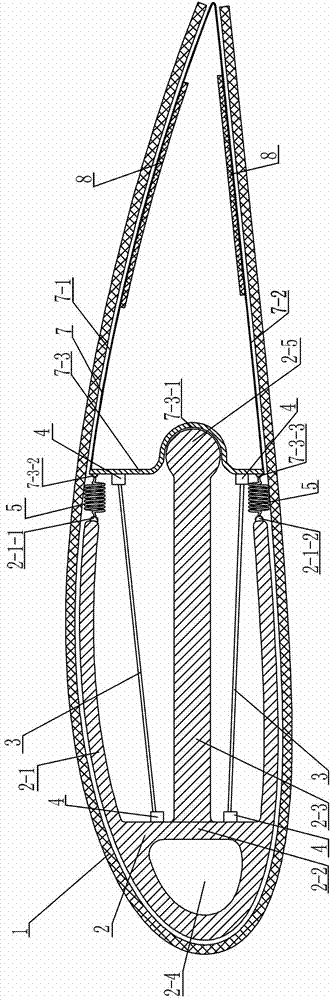

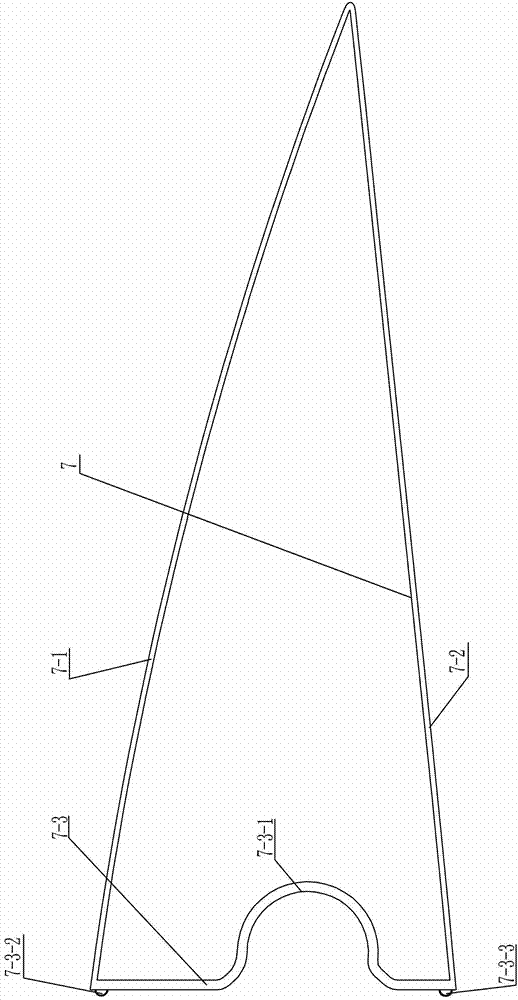

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment. A variable trailing edge wing driven by a combination of shape memory alloy and piezoelectric fiber composite material in this embodiment includes a skin 1, a fixed part 2, a movable part 7, and at least a pair of shape memory alloy wires 3. At least one pair of elastic parts 5 and at least one pair of piezoelectric fiber composite materials 8, the fixed part 2 is connected to the movable part 7 through at least one pair of elastic parts 5, and at least one pair of shape Memory alloy wire 3, the two ends of at least one pair of shape memory alloy wire 3 are respectively connected with the fixed part 2 and the movable part 7, the movable part 7 can rotate around the fixed part 2, and the skin 1 is wrapped around the fixed part 2 and the movable part 7 On the outer surface, the movable part 7 includes an upper plate 7-1, a lower plate 7-2 and a connecting plate 7-3, and the upper plate 7-1, the l...

specific Embodiment approach 2

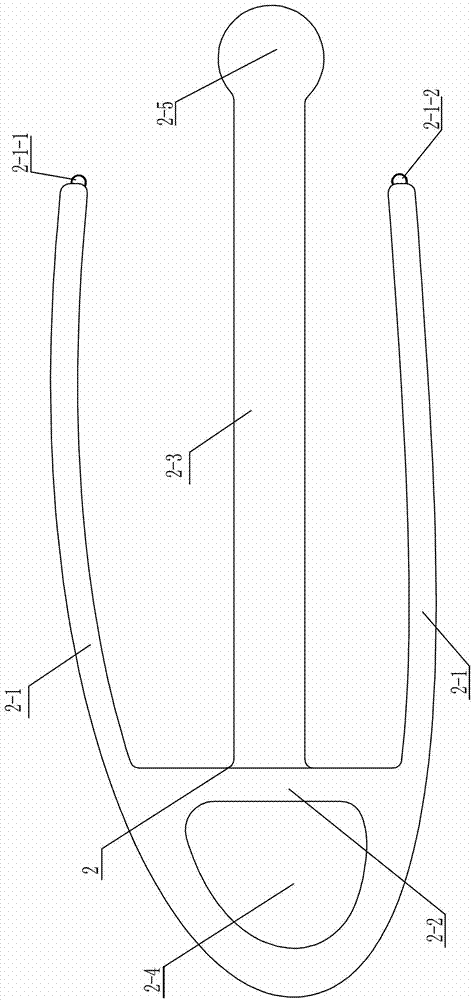

[0010] Specific implementation mode two: combination figure 1 and 2 Describe this embodiment, the fixture 2 in this embodiment includes an arc-shaped plate 2-1 and a vertical plate 2-2, the front end of the arc-shaped plate 2-1 is connected with a vertical plate 2-2, the vertical plate 2-2 and A through hole 2-4 is formed between the curved plates 2-1. Such arrangement facilitates the fixed connection with the aircraft body. The other specific embodiments are the same.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the fixing member 2 in this embodiment also includes a flat plate 2-3, a flat plate 2-3 is connected to the vertical plate 2-2, and the end of the flat plate 2-3 has a cylindrical boss 2-5, The middle part of the connecting plate 7-3 has a concave surface 7-3-1 matching the side of the cylindrical boss 2-5, and the side of the cylindrical boss 2-5 is attached to the concave surface 7-3-1 of the connecting plate 7-3. 1 on. With such arrangement, the design is reasonable and the structure is simple. When the SMA is driven, it can effectively realize that the movable part 7 can rotate around the fixed part 2, which is convenient and reliable. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com