Shifting fork device for transmission and automatic separation of upper roll system of grinding lathe

A technology of automatic separation and roller system, which is applied in the direction of grinding drive device, grinding machine parts, clutch, etc., can solve the problem of difficulty in unloading rollers, and achieve the effect of saving disassembly time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

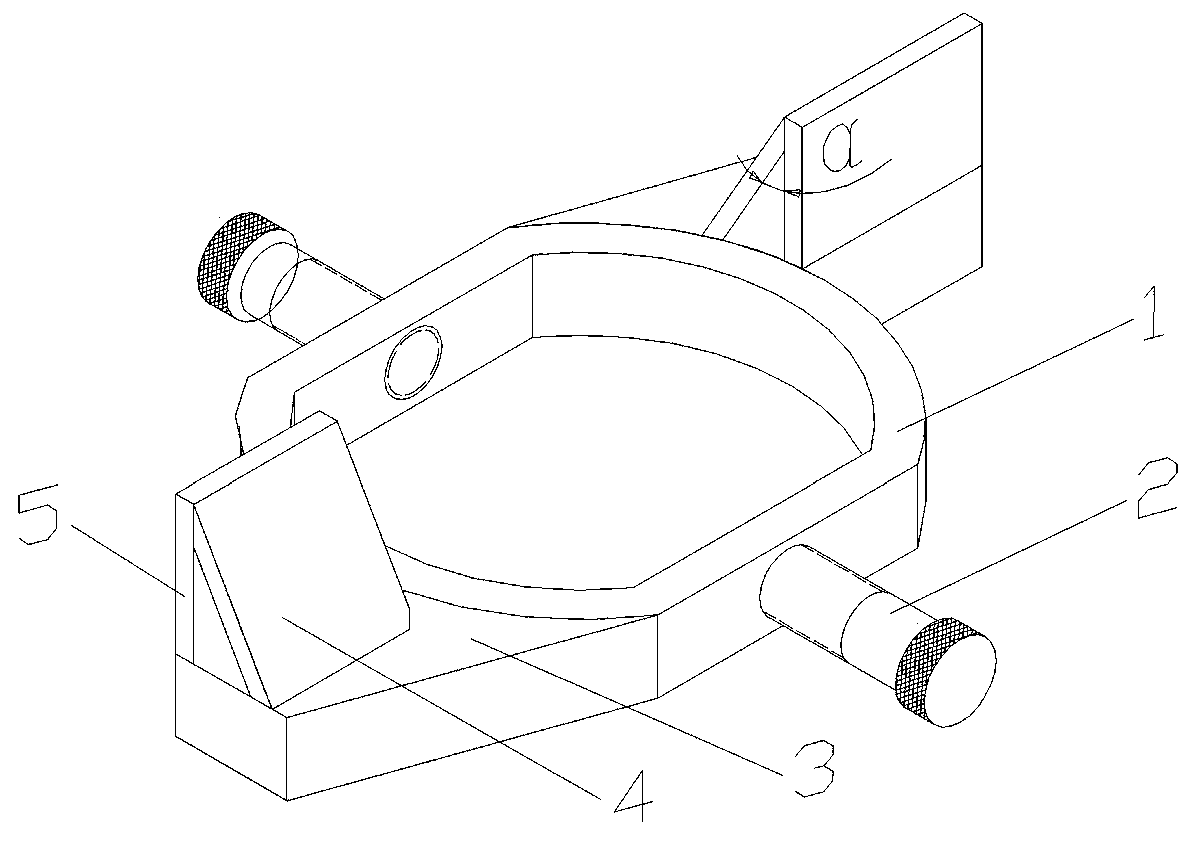

[0019] see figure 1 , 2 , the present invention has a frame 1, the frame 1 is composed of two oppositely arranged straight frames and two oppositely arranged arc-shaped frames, a threaded hole is opened at the center of the two straight frames, and a compression bolt is fitted. 2. An outwardly extending ear plate 3 is welded on each of the two arc-shaped frames, and the two ear plates 3 are alternately arranged left and right on the respective arc-shaped frames. The baffle 5, the two baffles 5 are respectively arranged on the staggered opposite sides of the two lugs 3, and the x-axis of the baffle 5 is arranged along the radial direction of the arc-shaped frame, and the y-axis of the baffle 5 is arranged along the axis of the inner hole of the frame , and two baffle plate backrests respectively are welded with a slant plate 4, and two slant plates 4 are relatively inclined to the outside.

[0020] In this embodiment, the inclination angles of the two swash plates are equal....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com