Pin shaft loading and unloading machine

A loader and pin technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of knocking and deformation of the pin head, laborious disassembly and assembly, labor and time consuming, etc., and achieves high assembly precision and efficiency. , mobile and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

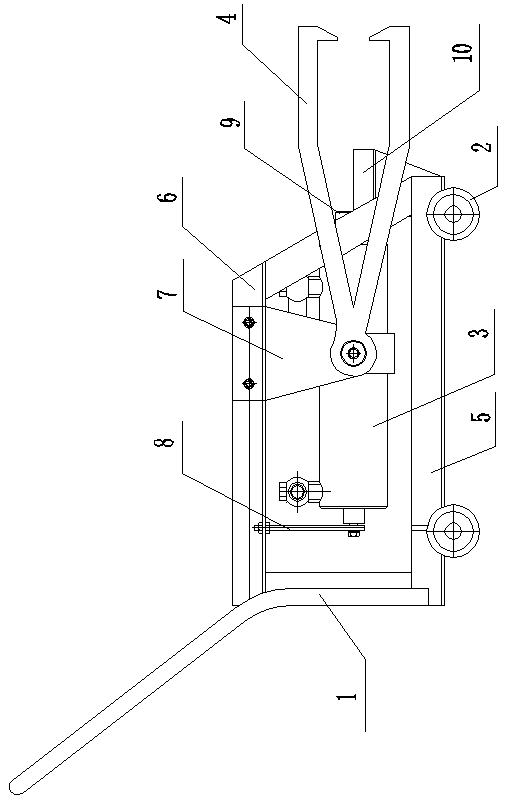

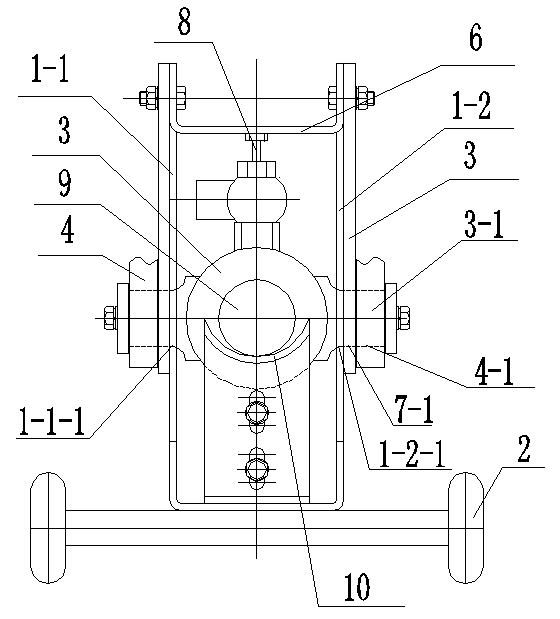

[0009] Such as figure 1 , 2 , 3, the present invention includes a frame 1, a roller 2 arranged around the bottom of the frame 1, a hinged hydraulic cylinder 3, two groups of tension rods 4; the bottom of the frame 1 above the roller 2 is provided with a random accessory platform 5 , the pin shaft placement platform 6 is set on the top of the frame 1; the hinged hydraulic cylinder 3 is arranged between the random accessory platform 5 and the pin shaft placement platform 6, on the left side wall 1-1 of the frame 1, and the right side wall 1- Shaft holes 1-1-1, 1-2-1 are respectively set on 2, and the twisted shafts 3-1 on both sides of the hinge type hydraulic cylinder 3 are respectively inserted in the corresponding shaft holes 1-1-1, 1-2- 1 inside; the outer sides of the left side wall 1-1 and the right side wall 1-2 of the frame 1 are respectively connected to the hanger 7 by nuts, and the first through holes corresponding to the twisted shaft 3-1 are respectively set at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com