Multiple-parameter monitoring system used for electric welding machine

A monitoring system and electric welding machine technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems such as difficulty in grasping parameters such as welding material weld position deformation, difficulty in grasping welding quality, and low product qualification rate. , to achieve the effect of intuitive display, convenient installation and layout, and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

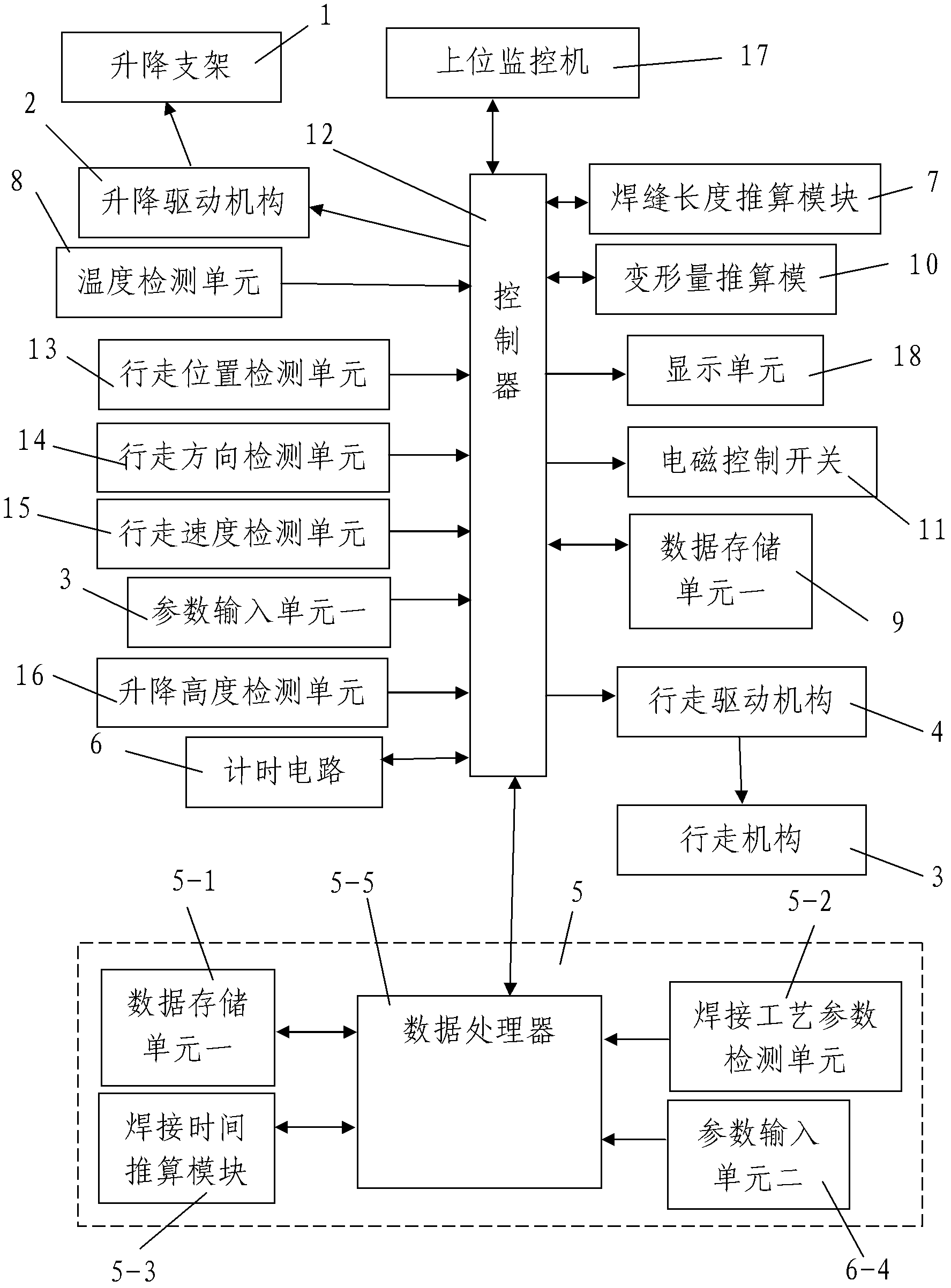

[0029] Such as figure 1 As shown, the present invention includes a lifting bracket 1 that is stably installed on a power supply welding machine and can be adjusted up and down, a lifting drive mechanism 2 that lifts and drives the lifting bracket 1, and is installed on the bottom of the lifting bracket 1 and can drive the electric welding machine on a horizontal operating platform. The walking mechanism 3 that moves freely on the top, the traveling driving mechanism 4 that drives the traveling mechanism 3, the electromagnetic control switch 11 connected in series in the power supply circuit of the electric welding machine, the welding speed estimation system 5 based on the welding depth estimation, and the The timing circuit 6 for automatically counting the welding time of the electric welding machine, the welding seam length estimation module 7 for automatically calculating the welding seam length at the current position according to the welding speed inferred by the welding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com