Transfusion container and manufacturing method thereof

A technology for an infusion container and a sealing container, which is applied to the field of infusion containers and sealing containers for infusion preparations, can solve the problems of complicated manufacturing process, puncture and debris, and the puncture device is easily pulled out of the dissolving solution container by accident, and achieves low production cost and fast assembly. , the effect of reducing the burden of drug prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

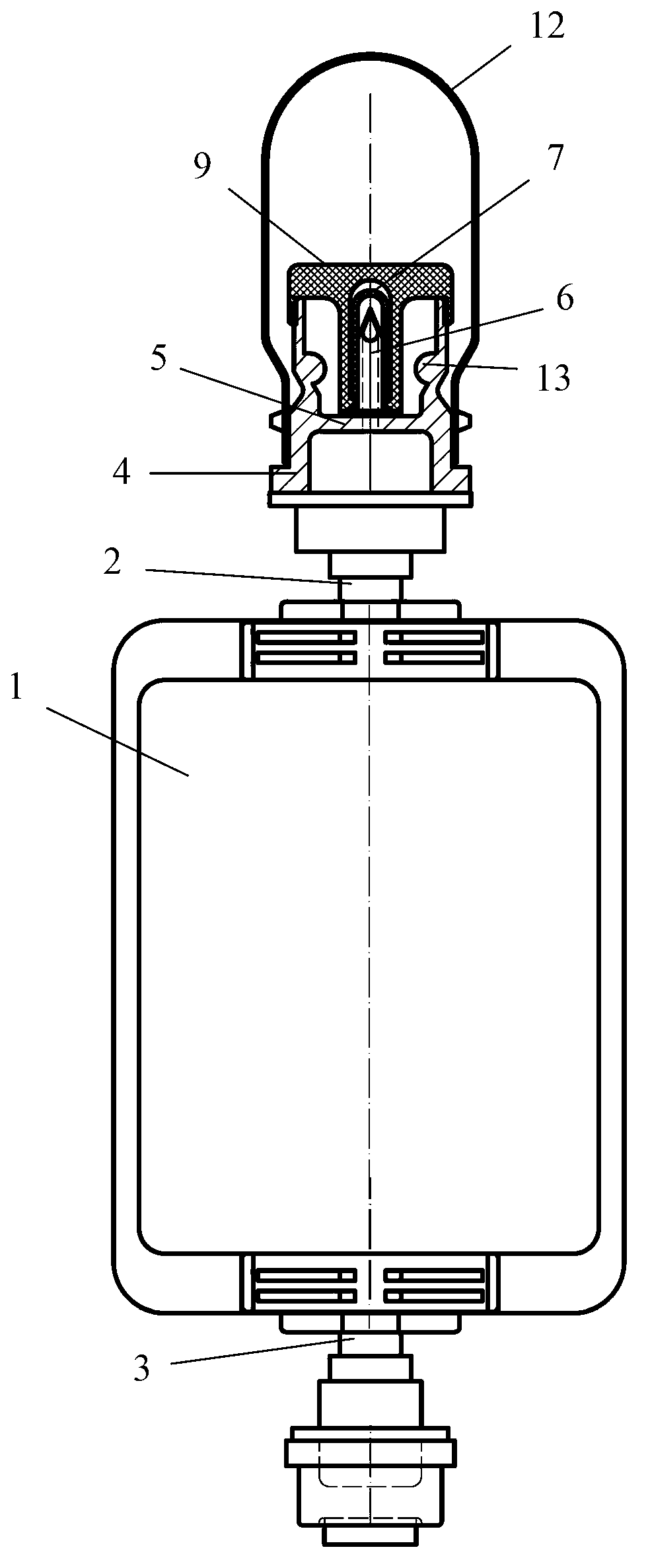

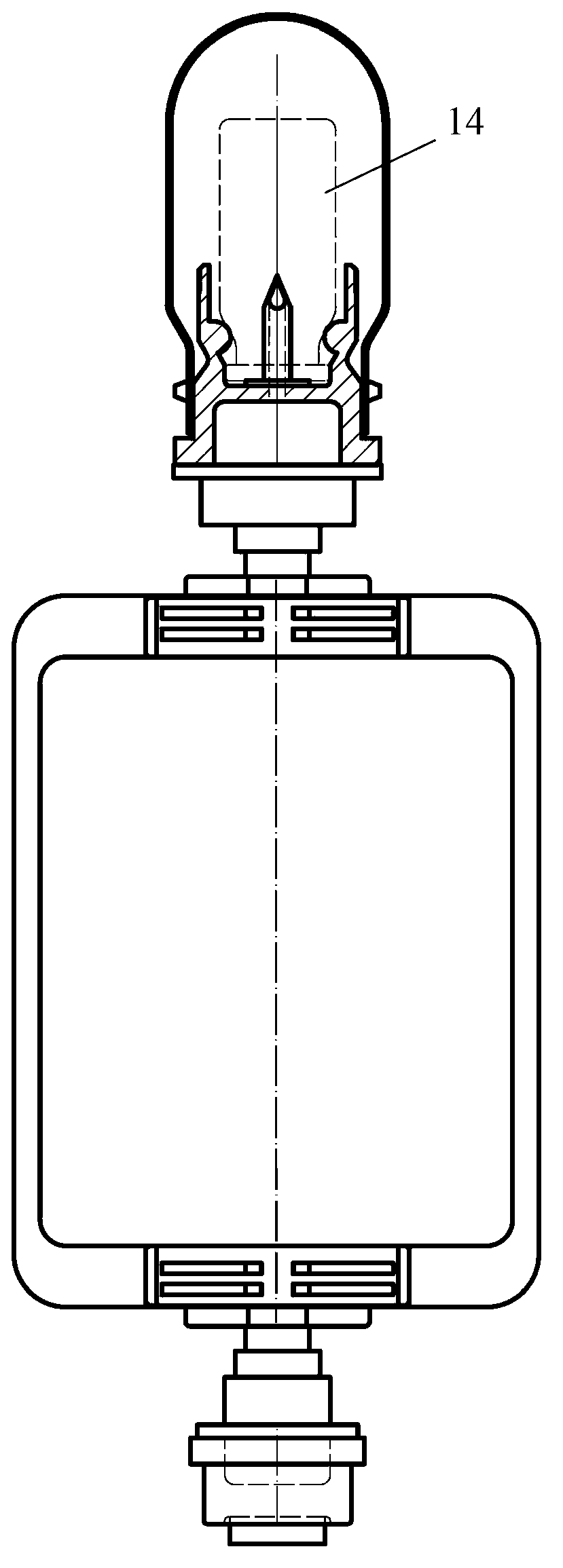

[0055] Such as figure 1 and figure 2 As shown, the transfusion container of the present invention comprises a sealed container 1, and the sealed container 1 is made of a soft bag, wherein, one end of the sealed container 1 is provided with a first mouth tube 2, and the other end of the sealed container 1 is provided with a first mouthpiece. Two mouth pipes 3, the first mouth pipe 2 and the second mouth pipe 3 communicate with the inner cavity of the sealed container 1 respectively, and the outer end of the first mouth pipe 2 is provided with a connector 4, and the connector 4 includes a sealing member 5 , the lower end of the sealing member 5 is sealingly connected with the outer end of the first mouth tube 2, a piercer 6 is arranged in the upper side of the sealing member 5, and the piercer 6 is made of a pipe with a sharp end, and the sharp end of the pipe points to the sealing Above the piece 5, there are two parallel passages inside the pipe, any one of which connects th...

Embodiment 2

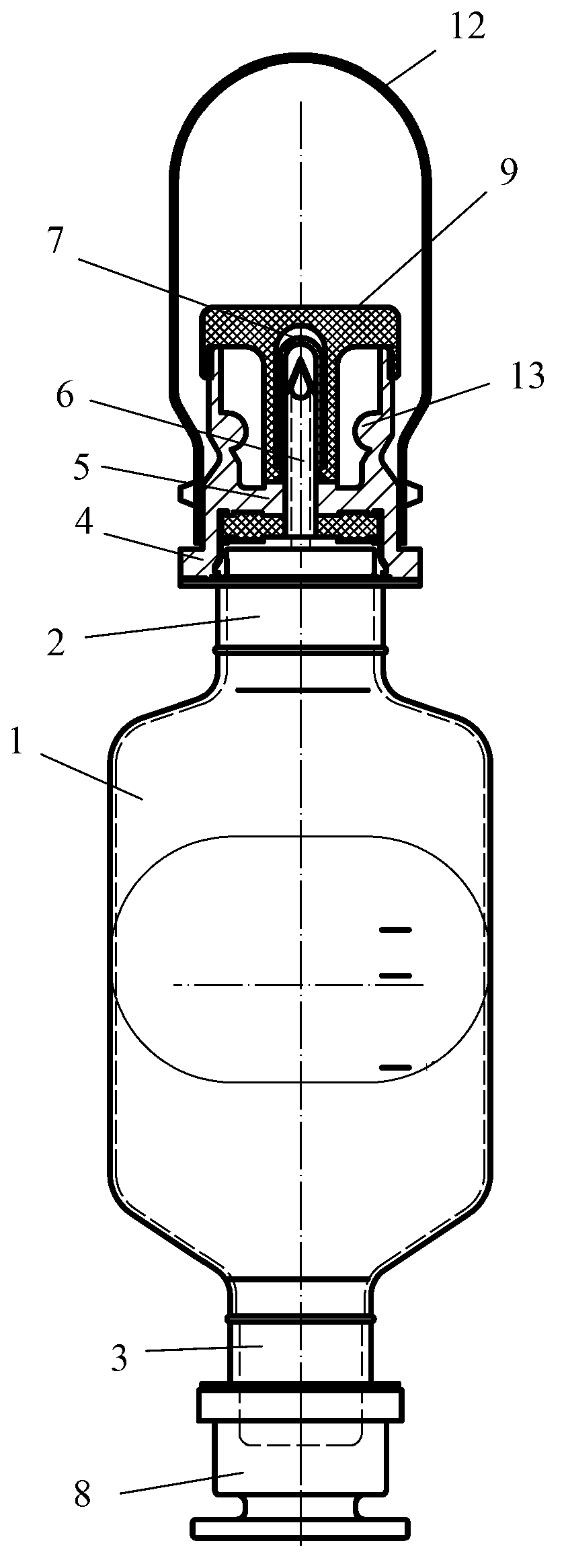

[0058] Such as image 3 and Figure 4 As shown, the transfusion container of the present invention includes a sealed container 1, and the sealed container 1 is composed of a bottle body, wherein, one end of the sealed container 1 is provided with a first mouth tube 2, and the other end of the sealed container 1 is provided with a first mouthpiece. Two mouth pipes 3, the first mouth pipe 2 and the second mouth pipe 3 communicate with the inner cavity of the sealed container 1 respectively, and the outer end of the first mouth pipe 2 is provided with a connector 4, and the connector 4 includes a sealing member 5 , the lower end of the sealing member 5 is sealingly connected with the outer end of the first mouth tube 2, a piercer 6 is arranged in the upper side of the sealing member 5, and the piercer 6 is made of a pipe with a sharp end, and the sharp end of the pipe points to the sealing Above the fitting 5, there are more than one channels in the fitting, any one of which is ...

Embodiment 3

[0077] Figure 13 Another structure of the present invention using a bottle body as a sealed container is shown. Such as Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, the connector 4 is connected to the first mouth tube 2, the connector 4 adopts a split structure, the connector 4 includes an outer cover 15 and a gasket 11, the sealing member 5 is arranged inside the outer cover 15, and the gasket 11 is arranged on the outer cover 15 and the sealing member 5, the piercer 6 passes through the outer cover 15 upwards, and the outer cover 15 is connected with the first port tube 2.

[0078] Such as Figure 18 As shown, the connector 4 adopts an integrated structure, and the piercer 6, the sealing member 5 and the outer cover 15 are integrally formed by injection molding.

[0079] The present invention also provides a method for producing the above infusion container, comprising the steps of:

[0080] The first step is to obtain a hollow bottle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com