Filter material for fluids and method for producing a filter material

A technology for filtering materials and fluids, applied in the field of filtering materials, can solve problems such as high cost and trouble, and achieve the effects of improved work performance, large filtering area, and low pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

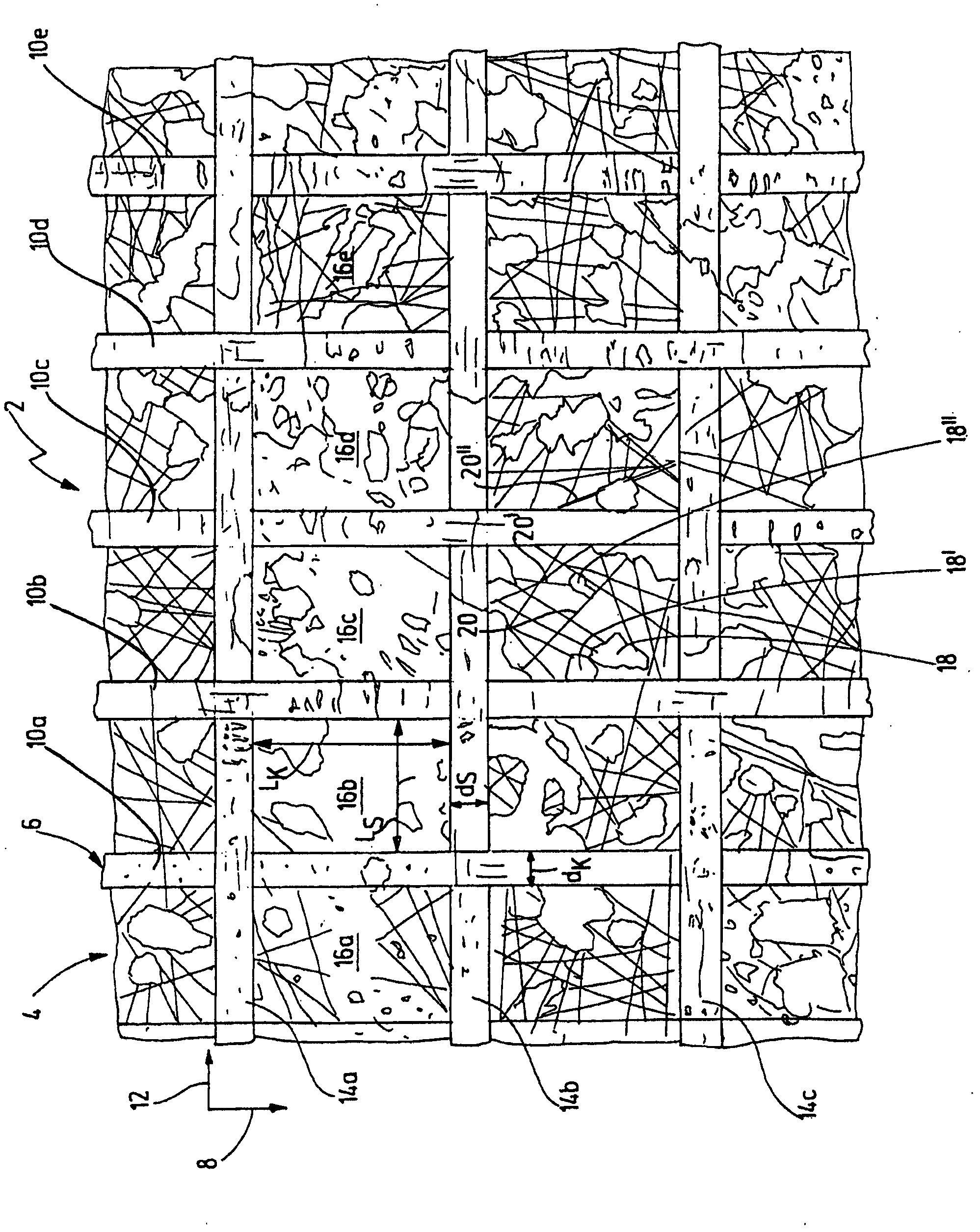

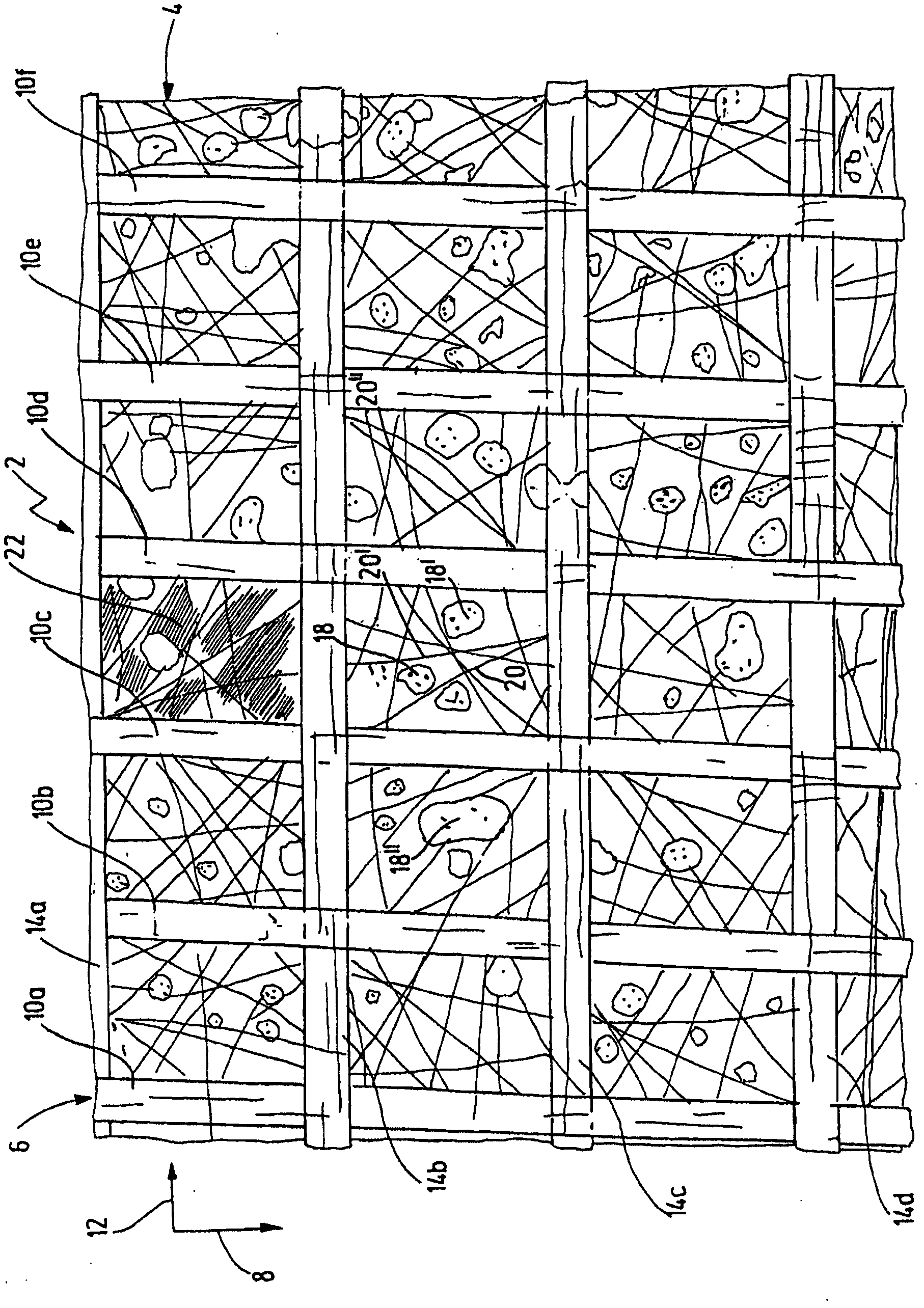

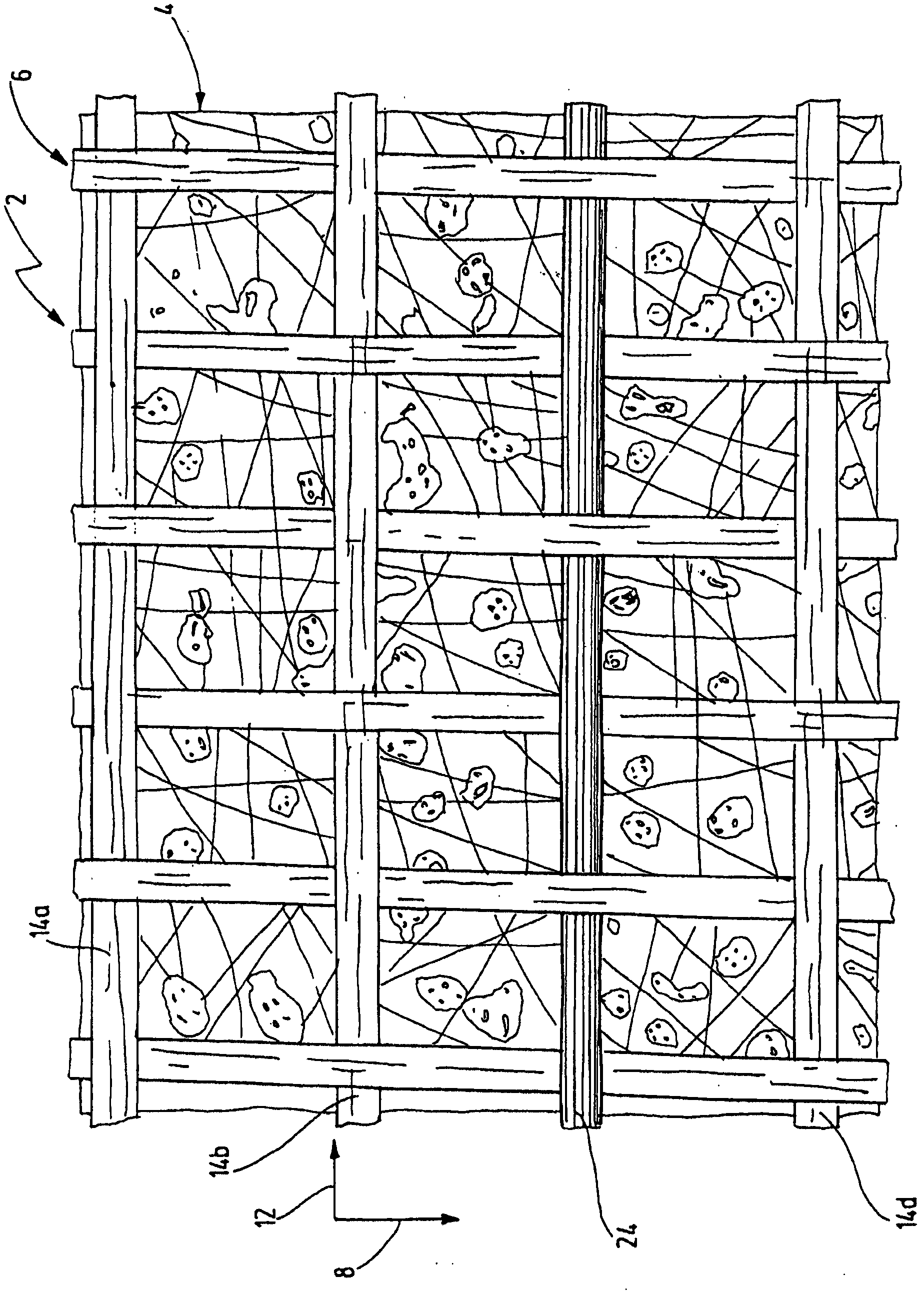

[0029] figure 1 It represents a rectangular section of filter material 2 , which is designed in planar form and is constructed in multiple layers from filter medium 4 and support structure 6 . The filter medium 4 consists of a plastic fleece in one layer. The support structure 6 comprises filament elements 10 a , 10 b , 10 c , 10 d , 10 e running in the warp direction 8 and further filament elements 14 a , 14 b , 14 c running in the weft direction 12 . The filament elements 10a, 10b, . . . , 14a, 14b, . . . form a regular fabric, wherein the filament elements 10a, 10b, . The interweaving is over and then under the nearest filament element 10a, 10b, . . . , 14a, 14b, . . . Filament elements 10a, 10b, . . . , 14a, 14b, . . . have substantially the same thickness d S 、d K . d K The values of are, for example, 246 microns and 262.4 microns; d S The values of , for example, are 252.6 microns and 242.8 microns. Furthermore, groups of filament elements 10a, 10b, ..., and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com