Electronic load module of power supply aging test and power supply aging test system

An electronic load, power aging technology, applied in power testing, parts of electrical measuring instruments, measuring electricity, etc., can solve the problems of inconvenient product quality analysis and evaluation, few optional specifications, large resistance error, etc. The mode and parameter settings are flexible and fast, convenient for system maintenance, and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

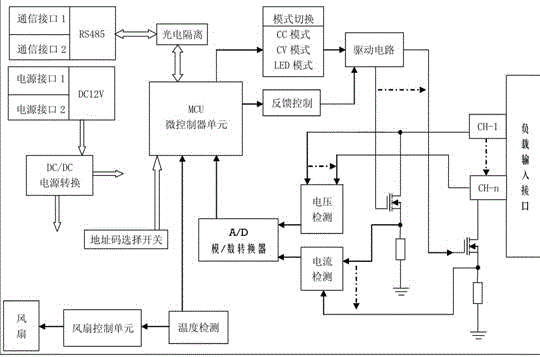

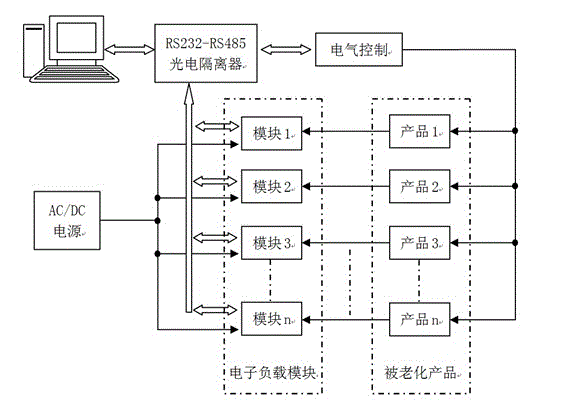

[0047] Example 1, such as figure 1 , figure 2 As shown, this embodiment is a power aging test system such as a power aging room or an aging car composed of a group of electronic load modules for power aging testing and a host computer, such as figure 2 As shown: the system can perform aging tests on several aging power supplies at the same time, and the host computer controls and monitors them uniformly, displays and records the test process, and realizes the automation and intelligence of power supply aging tests. The technical solution of the power supply aging test system is: the The power supply aging test system includes a group of electronic load modules for power supply aging test. The electronic load modules for each power supply aging test perform aging tests on the tested power supply respectively, and also includes a host computer. The host computer communicates with each The electronic load modules of the power aging test are connected to each other, receive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com