A method for judging the end point of donkey-hide gelatin blanching process based on electrical conductivity

A discriminant method, the technology of blanching donkey-hide gelatin skin, applied in the direction of material resistance, can solve the problems of inconsistent quality of donkey skin, inability to represent, and affect the production process, so as to avoid energy consumption and raw material loss, increase production capacity, and reduce process energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

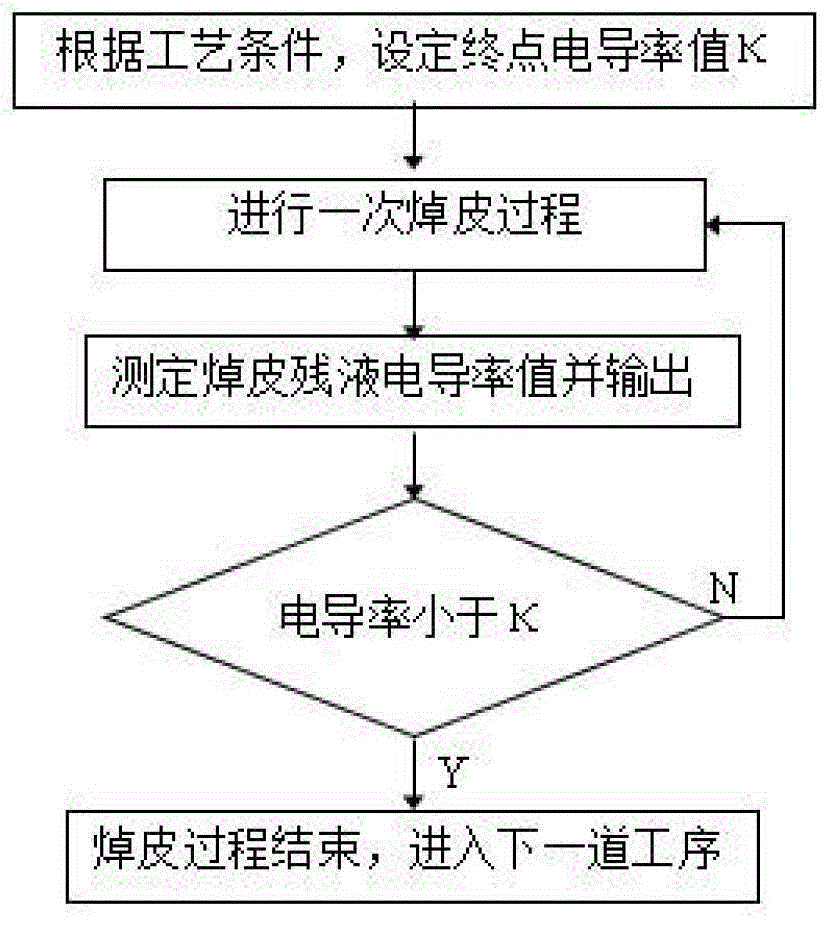

Method used

Image

Examples

Embodiment 1

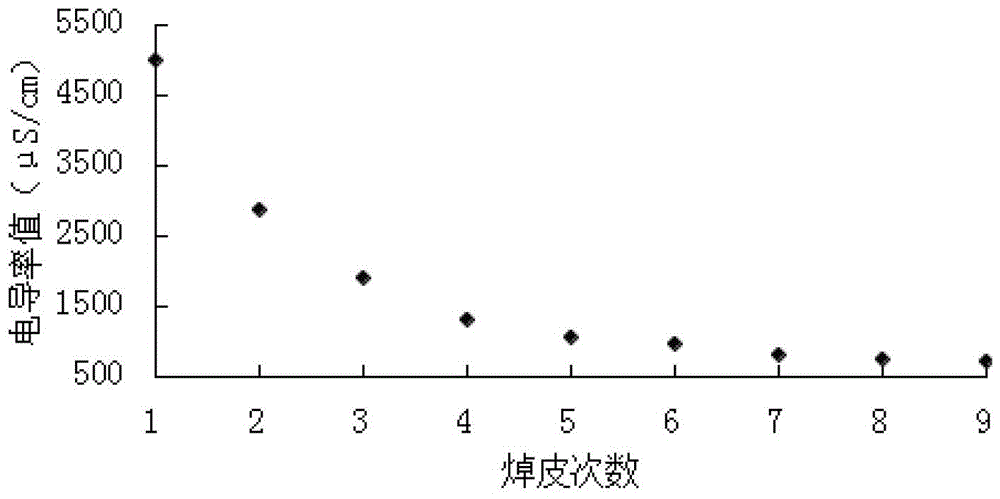

[0060] Put the raw donkey skin into the steaming ball, add water and sodium hydroxide, set the end-point conductivity value κ of the blanching skin residue to 750 μS / cm; discharge the blanching skin residue after heating and keeping warm, and measure its conductivity value, Record it as the first blanching; then add the same amount of water to the steaming ball several times, heat and keep warm, discharge the blanching residual liquid, measure its conductivity value κ, and output the change curve of the residual liquid conductivity value κ ; until the 9th time of blanching, the conductivity value of the blanching residual liquid was 712 μS / cm, which was lower than 750 μS / cm. It was considered that there was no need to carry out the next blanching, and the blanching process reached the end point, and entered the next process. The donkey-hide gelatin product finally obtained from this batch of raw materials has an ash content of 0.79% and a water-insoluble content of 1.20%, both ...

Embodiment 2

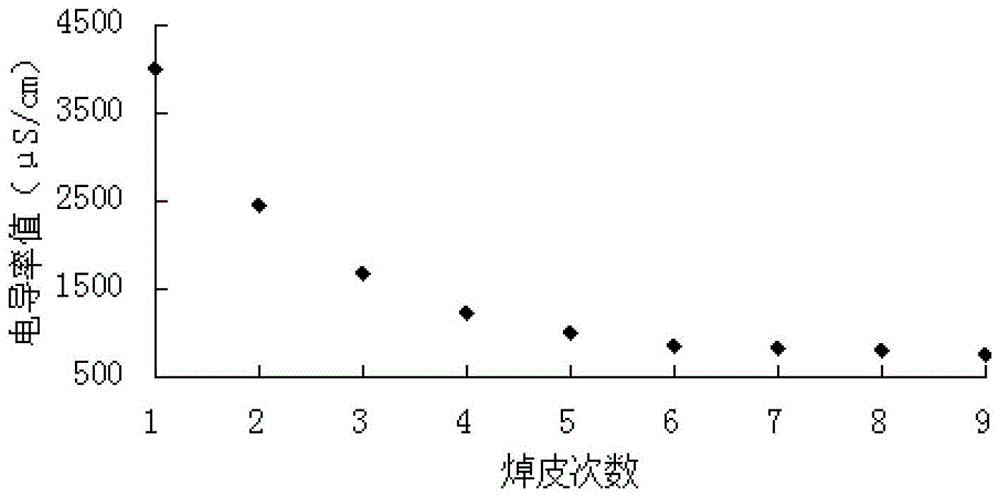

[0062] Put the raw donkey skin into the steaming ball, add water and sodium hydroxide, set the end-point conductivity value κ of the blanching skin residue to 750 μS / cm; discharge the blanching skin residue after heating and keeping warm, and measure its conductivity value, Record it as the first blanching; then add the same amount of water to the steaming ball several times, heat and keep warm, discharge the blanching residual liquid, measure its conductivity value κ, and output the change curve of the residual liquid conductivity value κ ; until the 9th time of blanching, the conductivity value of the blanching residual liquid was 749 μS / cm, which was lower than 750 μS / cm. It was considered that there was no need to carry out the next blanching, and the blanching process reached the end point, and entered the next process. The donkey-hide gelatin product finally obtained from this batch of raw materials has an ash content of 0.77% and a water-insoluble content of 1.12%, both ...

Embodiment 3

[0064] Put the raw donkey skin into the steaming ball, add water and sodium hydroxide, set the end-point conductivity value κ of the blanching skin residue to 750 μS / cm; discharge the blanching skin residue after heating and keeping warm, and measure its conductivity value, Record it as the first blanching; then add the same amount of water to the steaming ball several times, heat and keep warm, discharge the blanching residual liquid, measure its conductivity value κ, and output the change curve of the residual liquid conductivity value κ ; until the 14th time of blanching, the conductivity value of the blanching residual liquid was 732 μS / cm, which was lower than 750 μS / cm. It was considered that there was no need to carry out the next blanching, and the blanching process reached the end point, and entered the next process. The donkey-hide gelatin product finally obtained from this batch of raw materials has an ash content of 0.80% and a water-insoluble content of 1.06%, both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com