Non-contact temperature measuring device for monitoring of production process of quartz crucible

A technology of non-contact temperature measurement and quartz crucible, which is applied in the direction of measuring device, optical radiation measurement, radiation pyrometry, etc., can solve the problem of high price of thermocouple platinum rhodium thermocouple wire, relatively harsh requirements for thermocouple installation position, and influence on quartz Crucible molding and other problems, to achieve the effect of easy promotion and use, compact structure, and low maintenance and repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

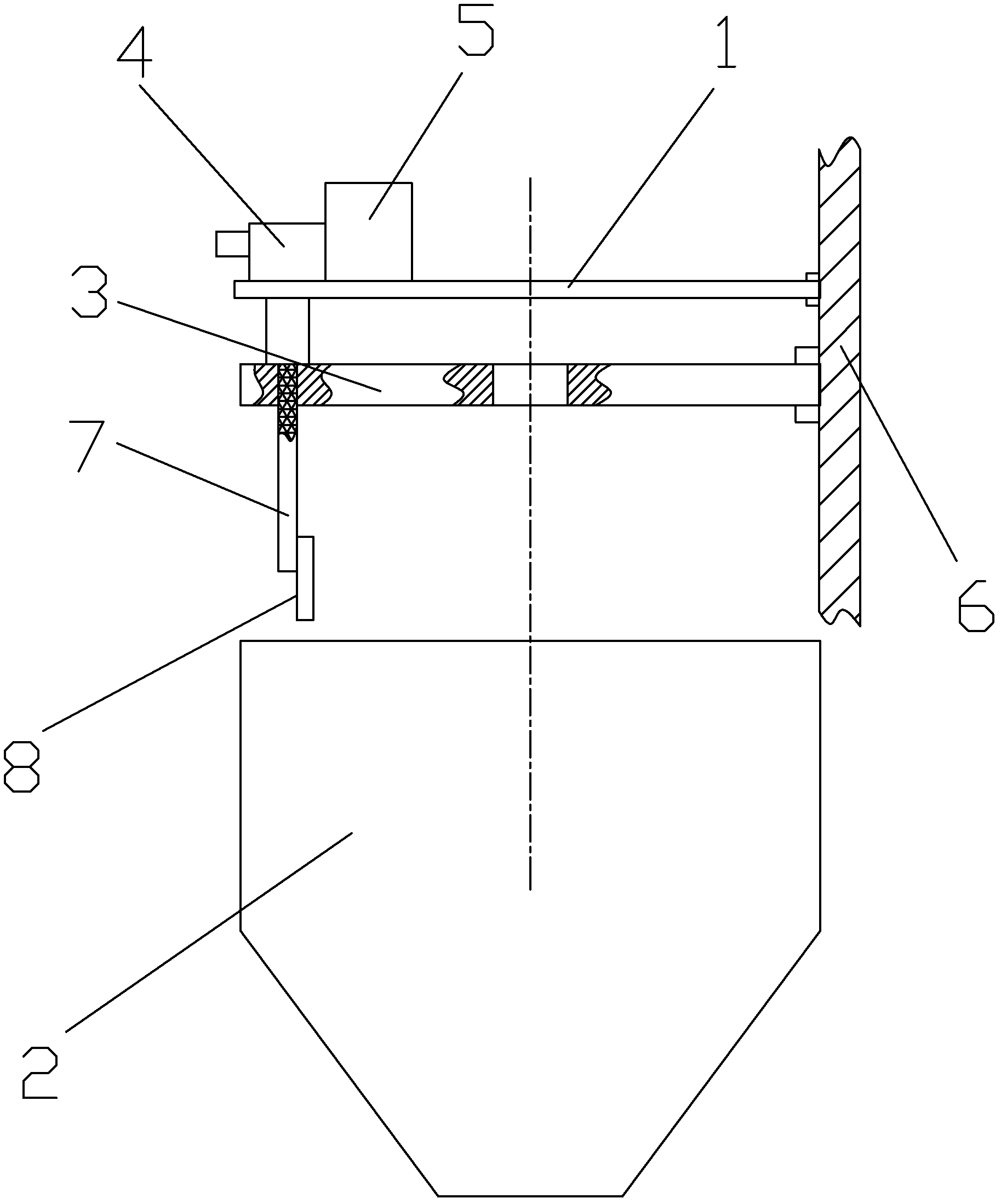

[0020] Such as figure 1 As shown, the present invention includes a mounting base 6 fixedly connected to the quartz sand distribution device, a sensor mounting bracket 1 fixedly connected to one side of the mounting base 6 perpendicular to the mounting base 6, and a sensor mounting bracket 1 fixedly connected to the mounting base 6 perpendicular to the mounting base 6. The heat shield 3 on one side of the mounting seat 6, the heat shield 3 and the sensor mounting bracket 1 are located on the same side of the mounting seat 6, the heat shield 3 is located directly above the quartz crucible mold 2 and is located on the Directly below the sensor mounting bracket 1, a non-contact temperature sensor 4 and a temperature indicator 5 connected to the non-contact temperature sensor 4 are installed above the sensor mounting bracket 1, and a temperature indicator 5 connected to the non-contact temperature sensor 4 is installed above the sensor mounting bracket 1. There is a photosensitive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com