A control method for deep hole blasting of adjustable pressure-bearing expansion plastic pipe

A technology of deep hole blasting and control method, applied in blasting and other directions, can solve the problems of low energy utilization rate of explosives in the hole, poor overall control effect of rock mass damage range, serious gas accident, etc., to expand the loosening and weakening control range, Improve energy utilization and simplify the effect of blasting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

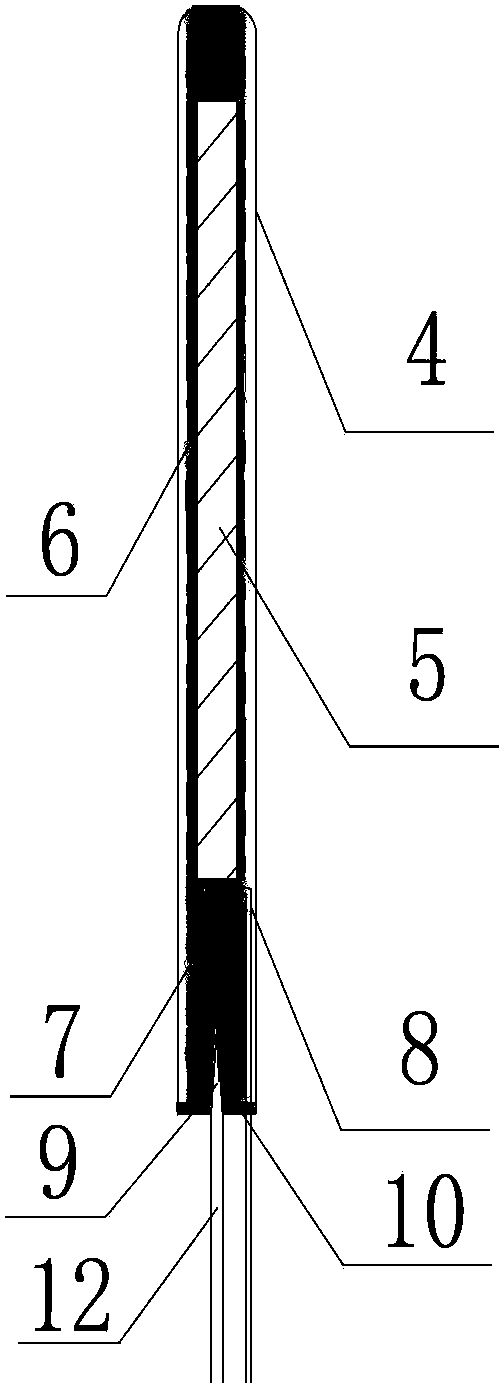

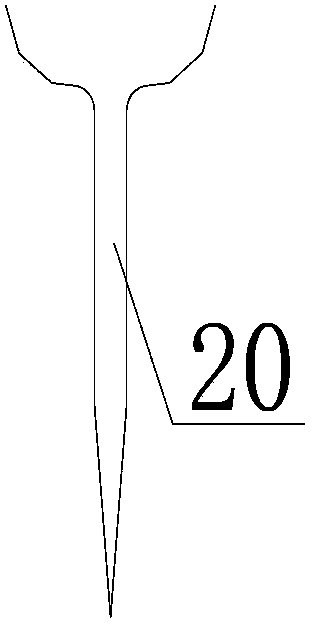

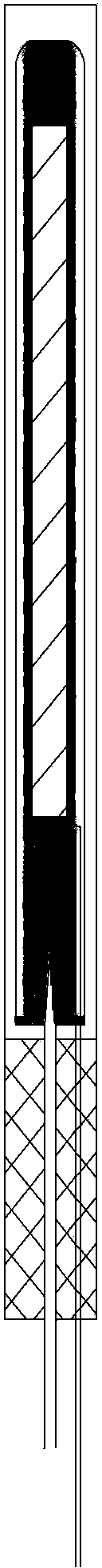

[0025] A blasting control method for adjustable pressure bearing of expanded plastic realizes the control of deep hole blasting in hard rock. , which includes a plastic adjustable pressure-bearing expansion tube sealed explosive device; the type of liquid, solid or solid-liquid mixed explosive transfer medium around the charge; the initial pressure setting of the explosive transfer medium and blasting safety protection measures. According to the depth of the blasting drilling, install a micro-expanded plastic tube of appropriate length and pre-sealed blast medium and appropriate amount of explosives in the hole. Referring to the pressure-bearing rock-breaking performance of the explosives and the size of the remaining space in the drilling hole, continue to inject into the plastic tube using a special transport device. Proper amount of detonation medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com