A kind of lateral ore-collapse blast hole structure and lateral ore-collapse method

A technology of blast hole and ore collapse, which is applied in the field of lateral collapse ore blast hole structure and its lateral collapse, which can solve the problems of high unit consumption, high powder ore rate, and large vibration, so as to reduce ore loss and reduce dust and harmful gases, reducing the effect of attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

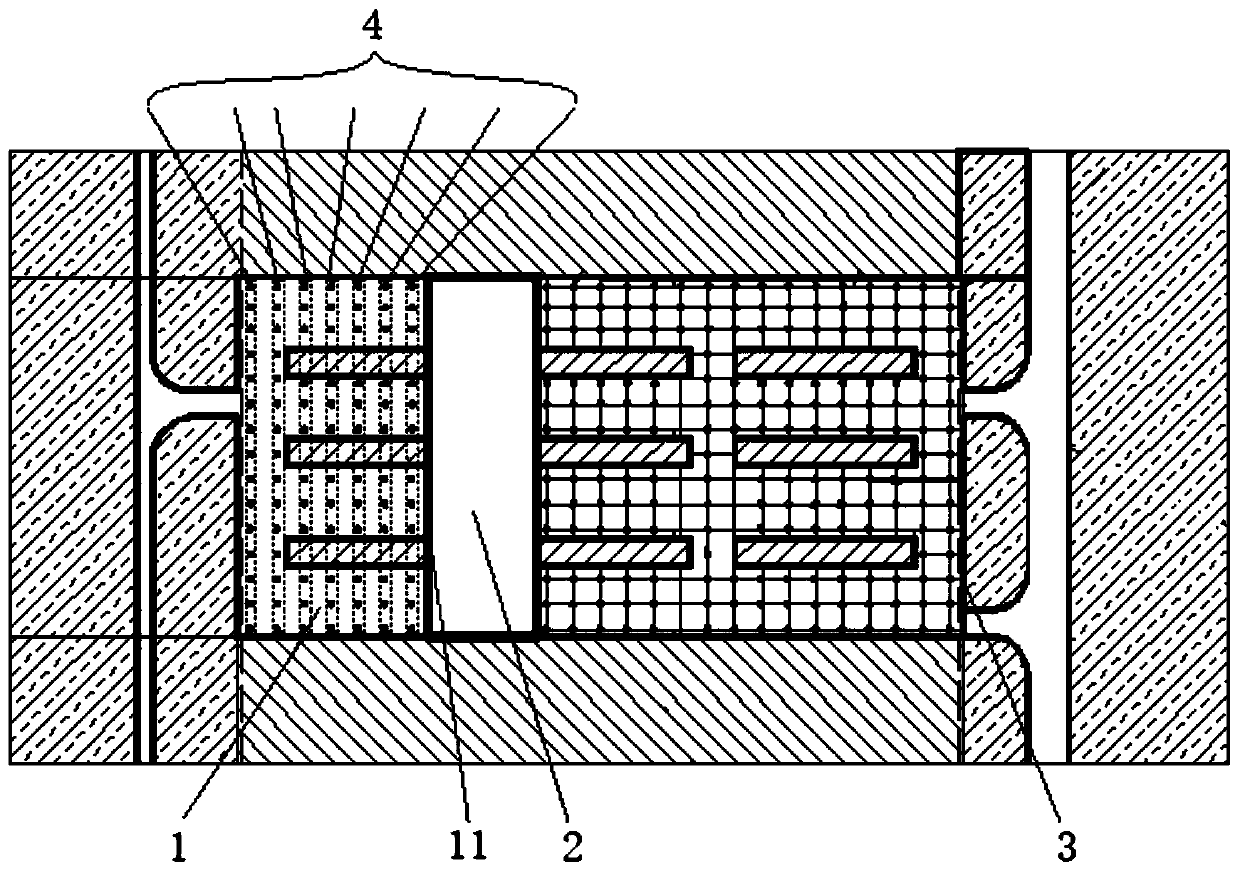

[0041] This embodiment is suitable for lateral collapse blasting in large-scale deep hole blasting, such as figure 1 As shown, after the mining area is divided into a slotting area and a lateral collapse area, after blasting and falling in the slotting area, the lateral collapse blasthole structure in this embodiment is used to control the area in the lateral collapse blasting area 1. The ore body undergoes lateral ore collapse, and a free surface 11 of lateral ore collapse is formed by the slot 2 in the slot. The blasting in the slotting area is a conventional blasting technology, and this embodiment will not be repeated here.

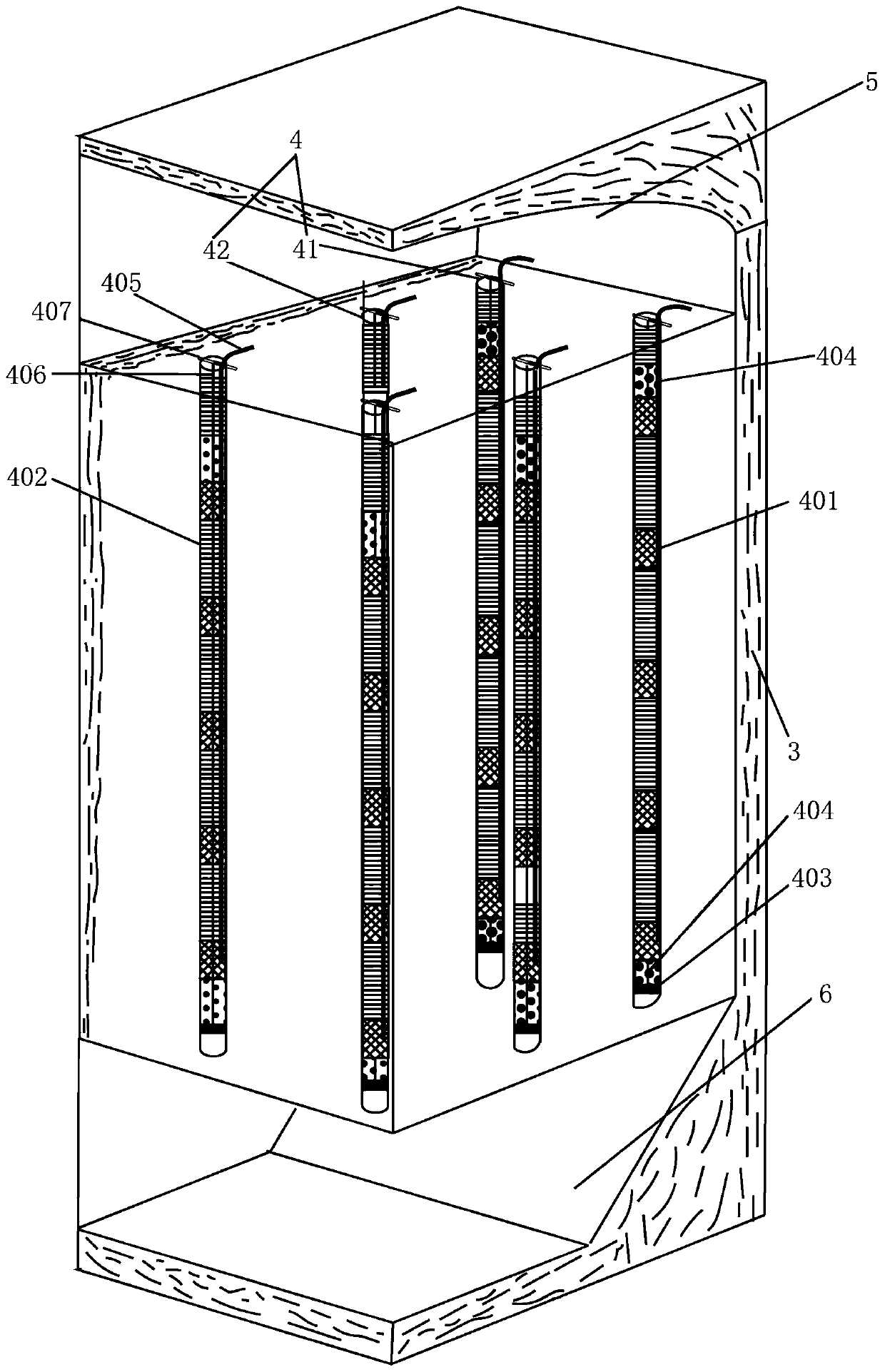

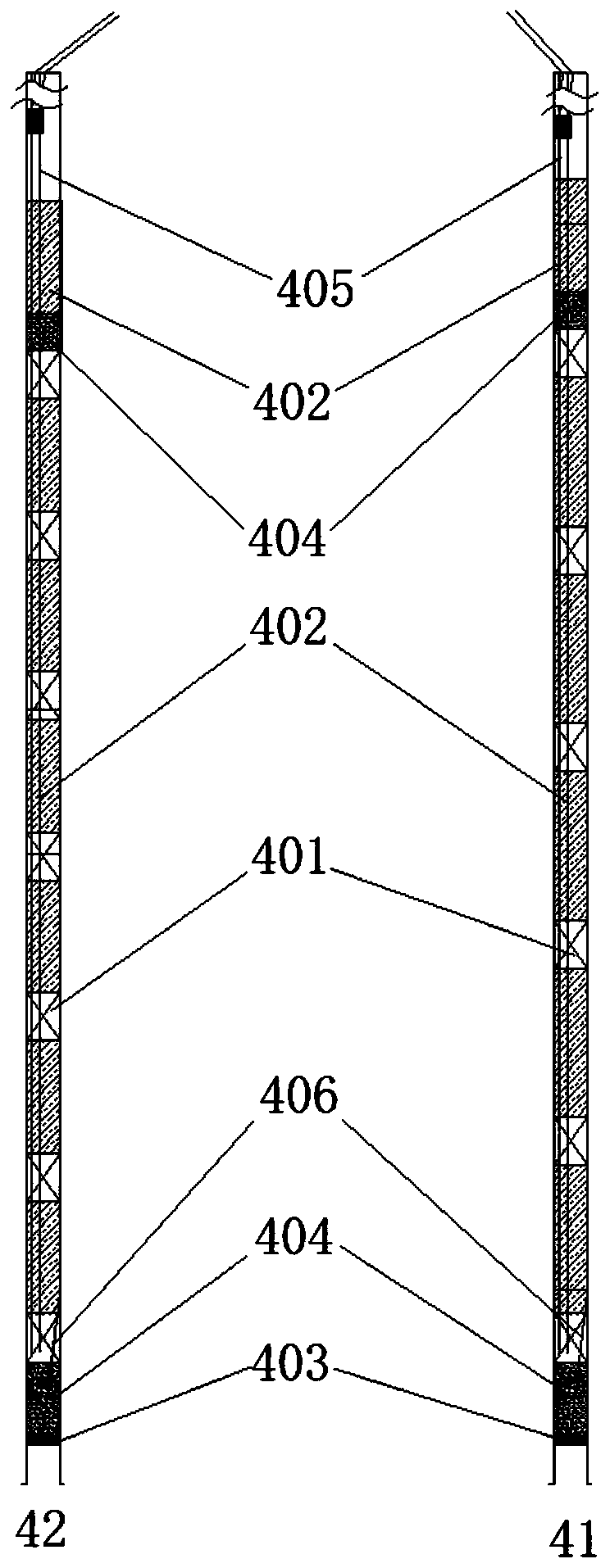

[0042] See also figure 2 with image 3 , The side collapse blasthole 4 in the picture is aimed at figure 1 The ore body in the lateral collapse blasting area 1 is subjected to lateral collapse blasting. The ore body in the free surface 11 of the lateral collapse is arranged with several rows of side collapse blastholes 4, of which one is close to the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com