Prospecting and short-hole shrinkage mining method of small inclined ore body

A shallow hole ore retention and mining method technology, applied in surface mining, underground mining, special mining, etc., can solve problems such as difficulty in grasping the boundary distribution of ore bodies, large amount of exploration and mining work, and large boundary changes, etc., to achieve reduction Effect of ore dilution rate, improvement of ore recovery rate, and reduction of engineering quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

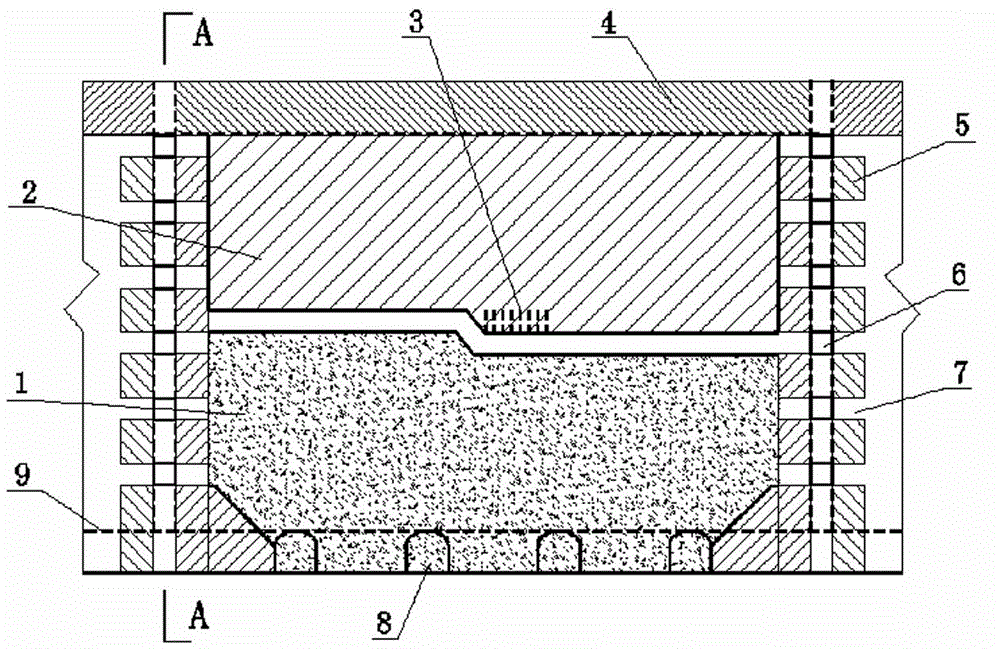

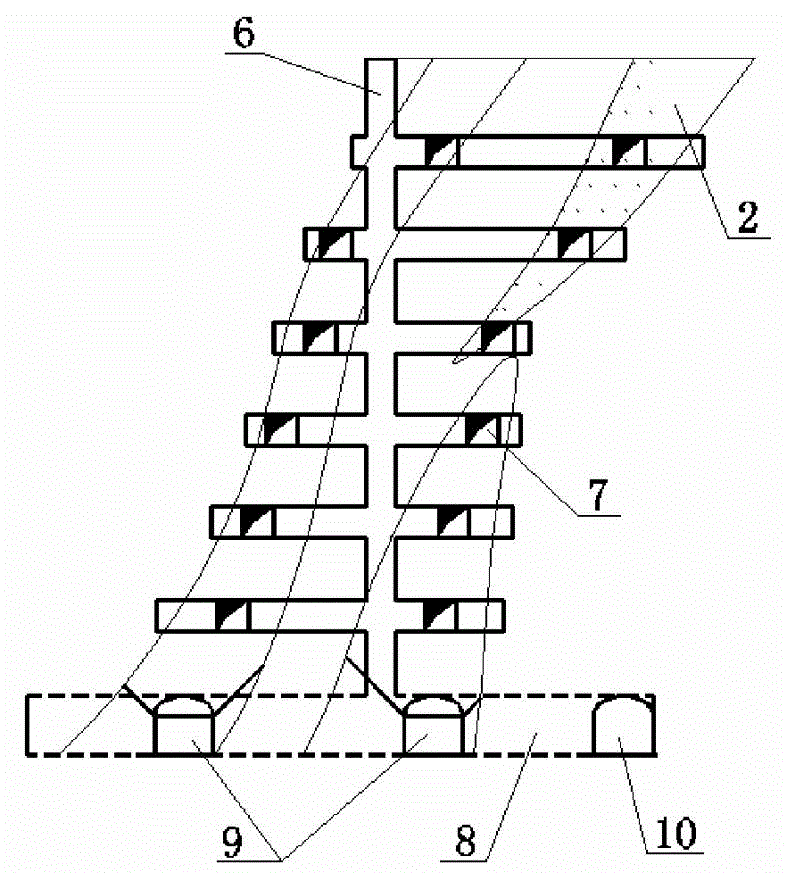

[0028] The Ⅱ1-4 and Ⅱ1-3 orebodies at an elevation of 560m~605m in the Dahongshan Iron Mine of Kunming Iron and Steel Group belong to the Hongshan Formation (Ptdh). The lithology of the first member of Hongshan Formation (Ptdh1) is light-colored sodic lava, and the uniaxial compressive strength of sodic lava is 59MPa~120MPa, which belongs to hard rock; the uniaxial compressive strength of iron ore is 36~ 102MPa, a semi-hard ore.

[0029] In the 560m segment, within the Ⅱ1-3 and Ⅱ1-4 ore bodies, excavate the prospecting roadway along the strike, and excavate the prospecting access road at an interval of 40m until the ore body is broken down. The proven ore bodies are produced in parallel strips, the hanging wall is Ⅱ1-4 ore body, the footwall is Ⅱ1-3 ore body, the average thickness of interlayered stones between the two ore bodies is 6.8m, and the trend is southeast-northwest. The inclination is 190°~210°, and the inclination is 60°~75°. The average thickness of Ⅱ1-4 ore body...

Embodiment 2

[0032] The Ⅱ1-8 and Ⅱ1-7 orebodies at the elevation of 480m~515m in the Dahongshan Iron Mine of Kunming Iron and Steel Co., Ltd. are all light-colored metasodic lavas, belonging to hard rocks; the uniaxial compressive strength of iron ore is 43~97MPa, belonging to semi hard ore.

[0033] In the 480m section, within the Ⅱ1-8 and Ⅱ1-7 ore bodies, excavate the prospecting roadways along the strike, and excavate the prospecting access roads at intervals of 50m until the ore bodies are broken down. The proven ore body is produced in strips, the hanging wall is Ⅱ1-8 ore body, and the footwall is Ⅱ1-7 ore body. There are interlayered stones with an average thickness of 4.5m between the two ore bodies, and the trend is east-west, with a dip of 180° ~205°, inclination 55°~75°. The average thickness of Ⅱ1-4 ore body is 7.5m, and the average thickness of Ⅱ1-3 ore body is 6.9m.

[0034] The prospecting connection road is used as the transportation roadway, and the main roadway for trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com