Dual-purpose detonating device for detonating perforating gun

A technology of detonating device and perforating gun, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve problems such as non-compliance, many joint points, and inconvenient use by users, so as to meet the requirements of ensuring pressure resistance and ensuring Reliability, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

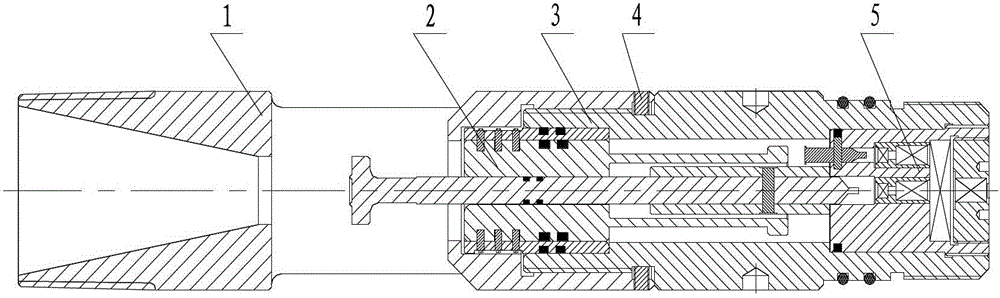

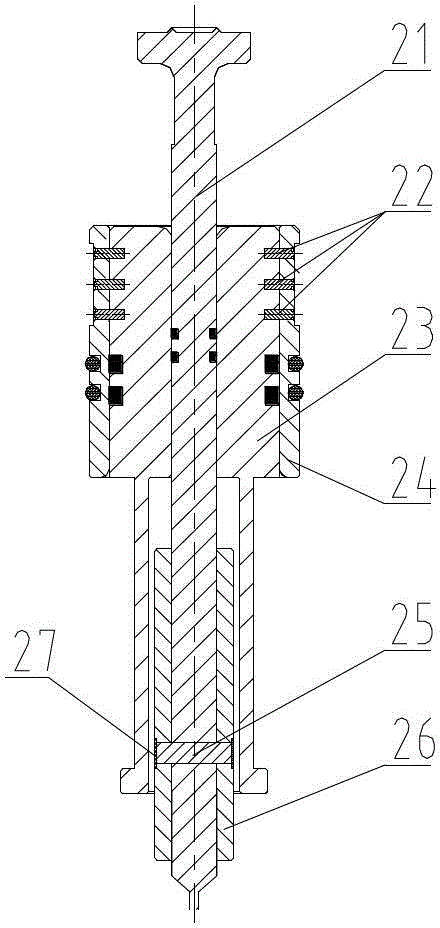

[0033] as figure 1 As shown, the preferred embodiment of the present invention includes an upper body 1, a piston assembly 2, a lower body 3, a screw 4, an explosion assembly 5 and several sealing rings. The upper body 1 is a hollow cylinder made of 40Cr steel and is provided with a variable cross-section through hole along the axis. The outside of the input end is provided with an external thread for connecting the oil pipe, the inside is a through hole with variable cross-section, and the inside of the output end is provided with an internal thread hole for connecting the lower body 3 . A rectangular sand discharge window is symmetrically opened in the center of the pipe wall, and four screw holes are evenly distributed on the outside of the output end. The lower body 3 is made of 40Cr steel, the outer side of the input end is an external thread connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com