Steel pipe pole enabling electro-transmission lead to be buried

A technology for power transmission wires and steel pipe poles, applied in the field of steel pipe poles, can solve the problems of large footprint and inability to lead power transmission wires to the ground, and achieve the effects of small footprint, easy operation and maintenance, and improved safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below:

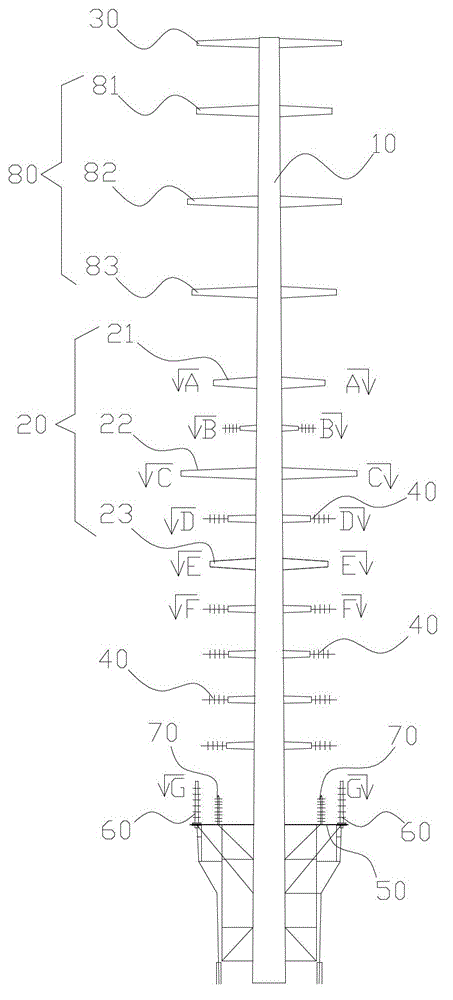

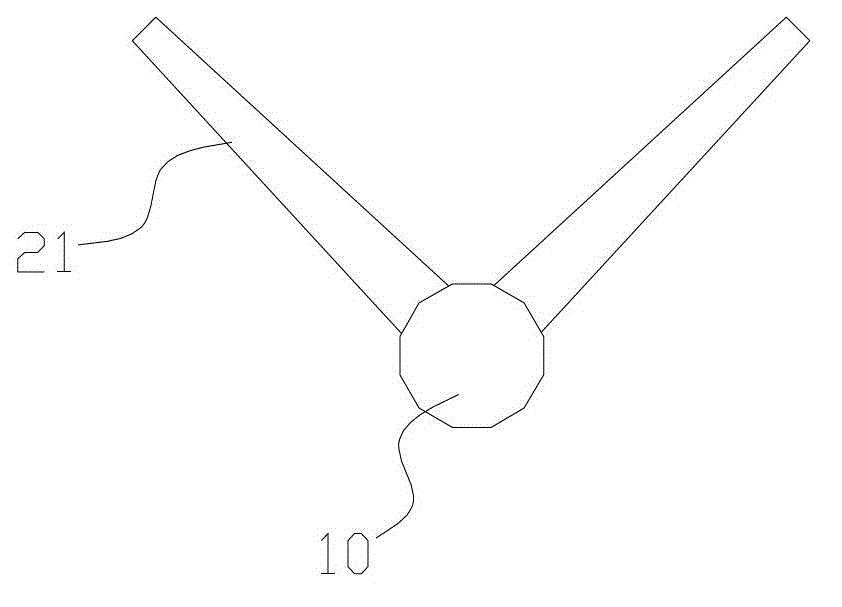

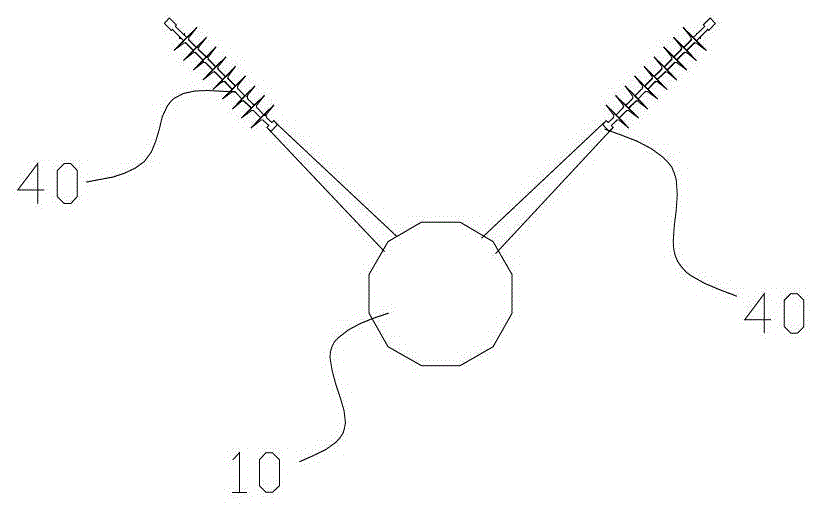

[0038] Such as Figure 1 to Figure 8 As shown, a steel pipe pole capable of burying power transmission wires includes a main pole 10, a ground wire cross arm 30 and three transfer cross arms 20, and the transfer cross arm 20 and the ground wire cross arm 30 are fixedly installed on the main on the rod 10, and the three transfer cross-arms 20 are arranged at intervals from top to bottom along the axial direction of the main rod 10, and each transfer cross-arm 20 is provided with a cable terminal head and a plurality of cross-arm insulators 40 correspondingly, The cross-arm insulator 40 is arranged above the cable terminal head and is fixedly connected to the main pole 10. The cable terminal head is arranged at the bottom of the main pole 10, and the plane perpendicular to the main pole 10 is used as a reference plane. The projections of different transfer cross-arms 20 on the reference plane are stagg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com