A kind of titanium-containing red mud composite binder and preparation method thereof

A binder and red mud technology, which is applied in the field of titanium-containing red mud composite binder and its preparation, can solve the problems of decreased total iron TFe content of finished pellets, decreased recovery rate of useful elements, and prohibitive manufacturers, to achieve The effects of high titanium content, improved pellet grade, and reduced process production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

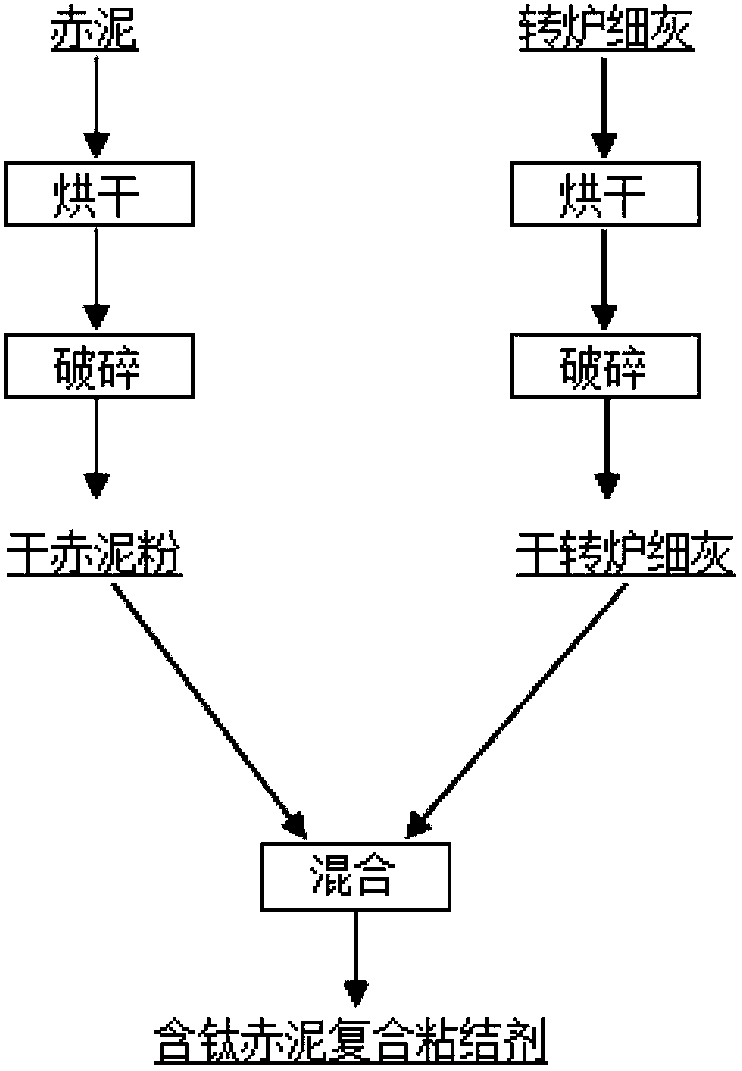

Method used

Image

Examples

Embodiment 1

[0028] Composition: TFe 21.54%, Al 2 o 3 18.56%, SiO 2 8.97%, TiO 2 7.6% of the red mud is dried with a chain grate (200°C), crushed by a ball mill, and 80% of the dry red mud powder with a particle size of less than 200 mesh is obtained; the converter fine ash with a composition of TFe 51.41% and CaO 4.81% is dried with a chain grate Dry machine drying (200°C) and ball mill crushing to obtain 80% dry converter fine ash with a particle size of less than 200 mesh; dry red mud powder and dry converter fine ash are mixed according to the mass percentage of 65:35, and the obtained titanium-containing red The composition of mud composite binder is TFe 31.99%, Al 2 o 3 12.06%, SiO 2 5.83%, TiO 2 4.94%, CaO 1.68%. After the titanium-containing red mud composite binder is used in the production of titanium-containing iron fine powder pellets, compared with calcium-based bentonite, the TFe of the pellets is increased by 1.54%, and the TiO 2 An increase of 0.15%; compared w...

Embodiment 2

[0030] Composition: TFe 40.76%, Al 2 o 3 11.48%, SiO 2 14.88%, TiO 2 6.23% of the red mud is dried with a chain grate (200°C), crushed by a ball mill, and 80% of the dry red mud powder with a particle size of less than 200 mesh is obtained; the converter fine ash with a composition of TFe 51.41% and CaO 4.81% is dried with a chain grate Dry machine drying (200°C) and ball mill crushing to obtain 80% dry converter fine ash with a particle size of less than 200 mesh; dry red mud powder and dry converter fine ash are mixed according to the mass percentage of 85:15, and the obtained titanium-containing red The composition of mud composite binder is TFe 42.35%, Al 2 o 3 9.76%, SiO 2 12.65%, TiO 2 5.29%, CaO 0.72%. After the titanium-containing red mud composite binder is used in the production of titanium-containing iron fine powder pellets, compared with calcium-based bentonite, the TFe of the pellets is increased by 2.03%, and the TiO 2 An increase of 0.16%, the eff...

example 3

[0032] Composition: TFe 40.76%, Al 2 o 3 11.48%, SiO 2 14.88%, TiO 2 6.23% of the red mud is dried with a chain grate (200°C), crushed by a ball mill, and 80% of the dry red mud powder with a particle size of less than 200 mesh is obtained; the converter fine ash with a composition of TFe 51.41% and CaO 4.81% is dried with a chain grate Dry machine drying (200°C) and ball mill crushing to obtain 80% dry converter fine ash with a particle size of less than 200 mesh; dry red mud powder and dry converter fine ash are mixed according to the mass percentage of 95:5, and the obtained titanium-containing red The composition of mud composite binder is TFe 41.29%, Al 2 o3 10.91%, SiO 2 14.14%, TiO 2 5.92%, CaO 0.24%. After the titanium-containing red mud composite binder is used in the production of titanium-containing iron fine powder pellets, compared with calcium-based bentonite, the TFe of the pellets is increased by 1.98%, and the TiO 2 An increase of 0.18%, the effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com