Cold-pressed high-strength fluorite pellet binder and use method thereof

A fluorite pellet and binder technology, which is applied in the field of cold-pressed high-strength fluorite pellet binder, can solve the problems of poor waterproofness, low cost and high cost, and achieves improved compressive strength, reduced cost, and improved waterproofness. sexually weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

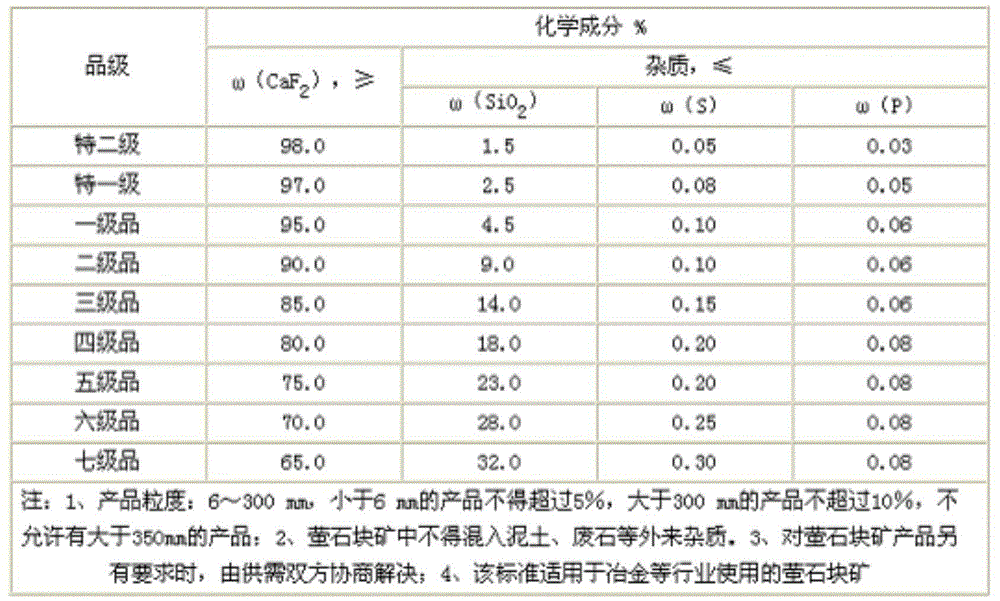

[0012] To produce fluorite balls with a content of 85% according to the third-grade standard in the fluorite lump ore quality standard (GB8216-87), use one ton of fluorite powder with an ore degree of 87 degrees and a moisture content of 4% to 5% after drying. , into the stone mill mixer, first add 20 kg of sodium metasilicate pentahydrate in the binder of the present invention and mix for 3 to 10 minutes, then add 15 kg of water glass and 0.3 kg of polyacrylamide successively, and stir for 3 to 10 minutes after each addition. Minutes, and then stir together for 5-30 minutes to make it fully mixed, then send it to a cold press molding machine to be pressed into balls, and then send it to a drying oven at a temperature of 150°C-170°C for 30-50 minutes to reduce the moisture to 1 Below %, pack into bags after cooling. This pellet meets the third grade standard in the quality standard of fluorite lump ore (GB8216-87). The cold-pressed high-strength fluorite pellet binder of the ...

Embodiment 2

[0014] To produce fluorite balls with a content of 85% according to the third-grade standard in the fluorite lump ore quality standard (GB8216-87), use one ton of fluorite powder with an ore degree of 88 degrees and a moisture content of 4% to 5% after drying. , into the stone mill mixer, first add 40 kg of sodium metasilicate pentahydrate in the binder of the present invention and mix for 3 to 10 minutes, then add 15 kg of water glass and 0.5 kg of polyacrylamide successively, and stir for 3 to 10 minutes after each addition. Minutes, and then stir together for 5-30 minutes to make it fully mixed, then send it to a cold press molding machine to be pressed into balls, and then send it to a drying oven at a temperature of 150°C-170°C for 30-50 minutes to reduce the moisture to 1 Below %, pack into bags after cooling. This pellet meets the third grade standard in the quality standard of fluorite lump ore (GB8216-87). The cold-pressed high-strength fluorite pellet binder of the ...

Embodiment 3

[0016] To produce fluorite balls with a content of 85% according to the third-grade standard in the fluorite lump ore quality standard (GB8216-87), use one ton of fluorite powder with an ore degree of 90 degrees and a moisture content of 4% to 5% after drying. , into the stone mill mixer, first add 60 kg of sodium metasilicate pentahydrate in the binder of the present invention and mix for 3 to 10 minutes, then add 20 kg of water glass and 0.5 kg of polyacrylamide successively, and stir for 3 to 10 minutes after each addition. Minutes, and then stir together for 5-30 minutes to make it fully mixed, then send it to a cold press molding machine to be pressed into balls, and then send it to a drying oven at a temperature of 150°C-170°C for 30-50 minutes to reduce the moisture to 1 Below %, pack into bags after cooling. This pellet meets the third grade standard in the quality standard of fluorite lump ore (GB8216-87). The cold-pressed high-strength fluorite pellet binder of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com