Method for recovering ammonia and synthesis gas from coking wastewater

A technology for coking wastewater and synthesis gas, which is applied in chemical instruments and methods, ammonia preparation/separation, and combustible gas production, etc., can solve the problems of increasing the cost of chemicals and energy consumption, ineffective utilization, secondary pollution, etc. The effect of realizing resource utilization, realizing effective utilization, and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

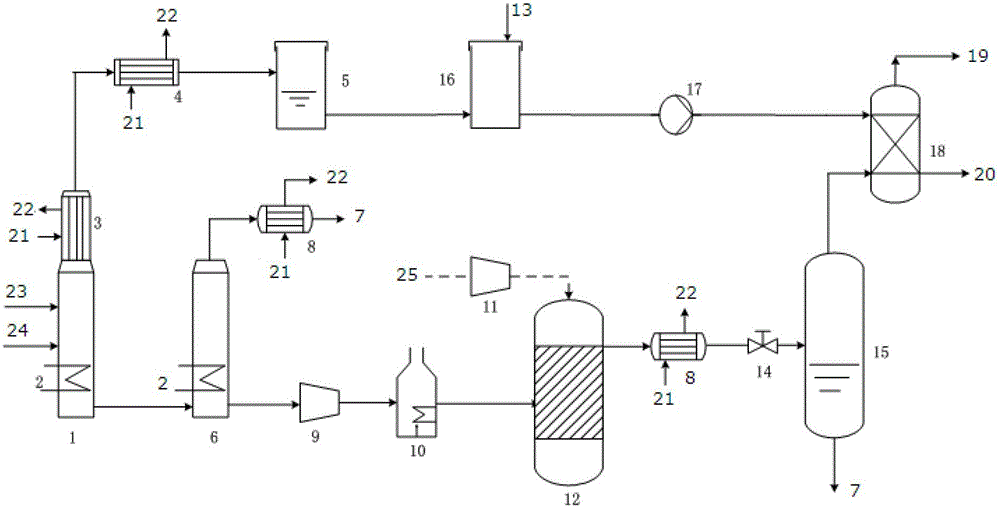

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] refer to figure 1 , the treatment capacity is 5t / h of coking wastewater, in which COD is 20000mg / L, and the concentrations of phenol and ammonia are 8000 and 7000mg / L respectively. The coking waste water 24 to be treated first enters the ammonia distiller 1, and at the same time, an appropriate amount of 10% NaOH solution is added to the ammonia distiller 1 to adjust the pH of the wastewater in the ammonia distiller to 11. Turn on the heater 2 at the bottom of the ammonia distiller to raise the temperature of the waste water to 80°C, and the top fluid (mainly NH 3 and water vapor) is condensed to 70°C through the compressor 3, then cooled to normal temperature through the condenser 4, and then enters the concentrated ammonia water storage tank 5. The fluid at the bottom of the ammonia distiller 1 enters the waste water concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com