Three-phase fluidized continuous reaction device for preparing rutile by hydrochloric acid leaching method

A reaction device, three-phase flow technology, applied in the direction of titanium dioxide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of long reaction time, short reaction time, low reaction temperature, etc., and achieve good heat and mass transfer effect. , The effect of easy temperature control and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

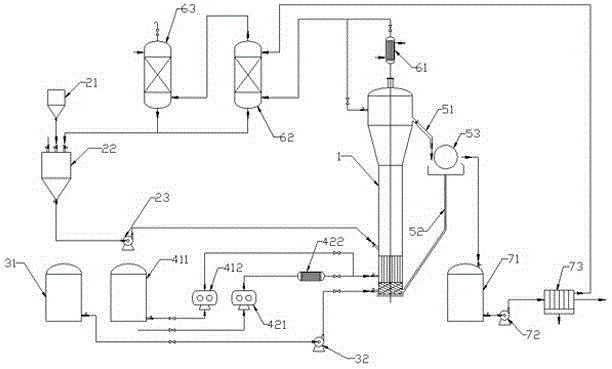

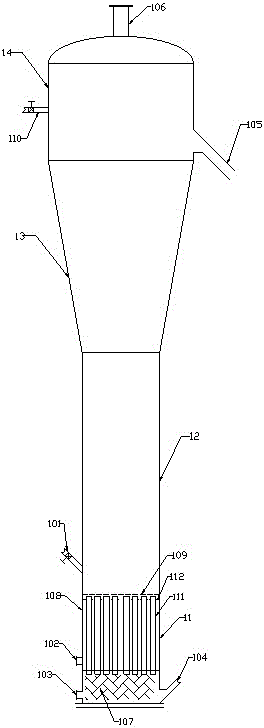

[0046] see figure 1 , the present invention provides a three-phase fluidized continuous reaction device for preparing rutile by hydrochloric acid leaching, which includes a three-phase fluidized reactor 1, a titanium concentrate feeding system, a gas inlet system, a liquid inlet system and an acidolysis solution circulatory system.

[0047] (1) The titanium concentrate feeding system consists of titanium concentrate silo 21 , titanium concentrate premix tank 22 and anti-corrosion mortar pump 23 , and is used to transport solid materials to the three-phase fluidized reactor 1 . The titanium concentrate silo 21 is used to store the titanium concentrate solid raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com