Dual-tank dense-phase pneumatic conveying device

A pneumatic conveying and dense-phase technology, which is applied in the conveying of dry materials and in the field of double-tank dense-phase pneumatic conveying devices, can solve the problems that the pneumatic conveying device cannot meet the conveying requirements, and the conveying requirements of regenerated sand or new sand are high, and the land occupation size can be achieved. Small, simple structure, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

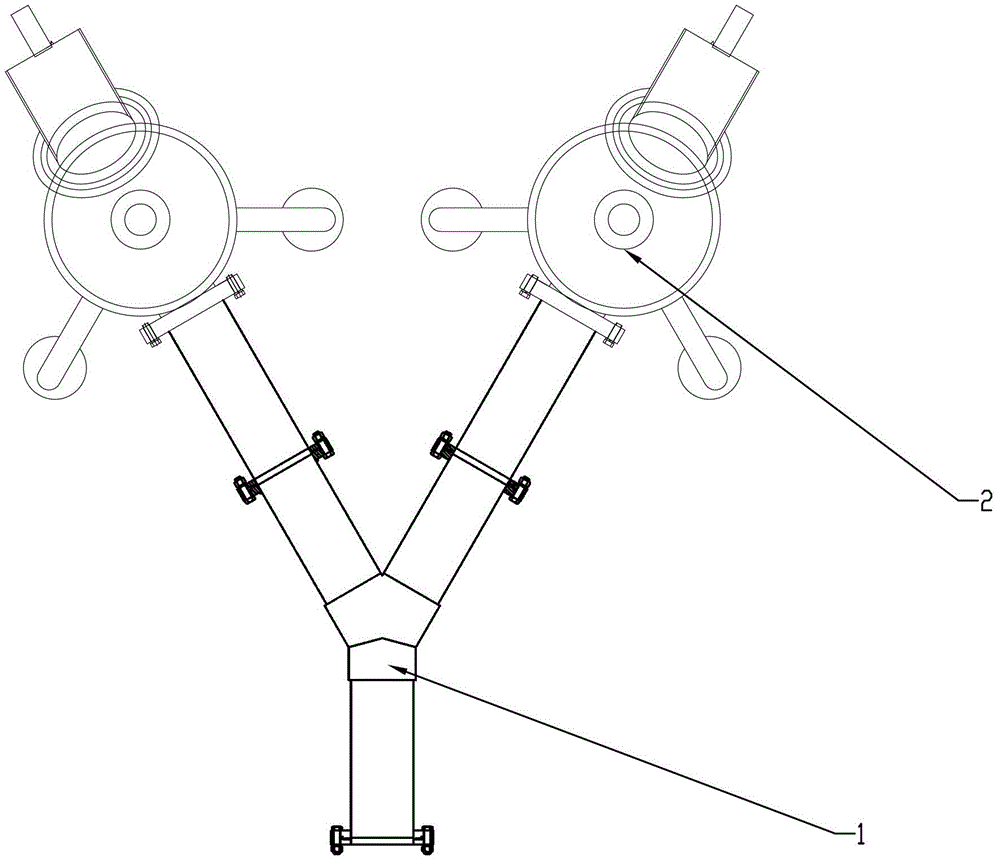

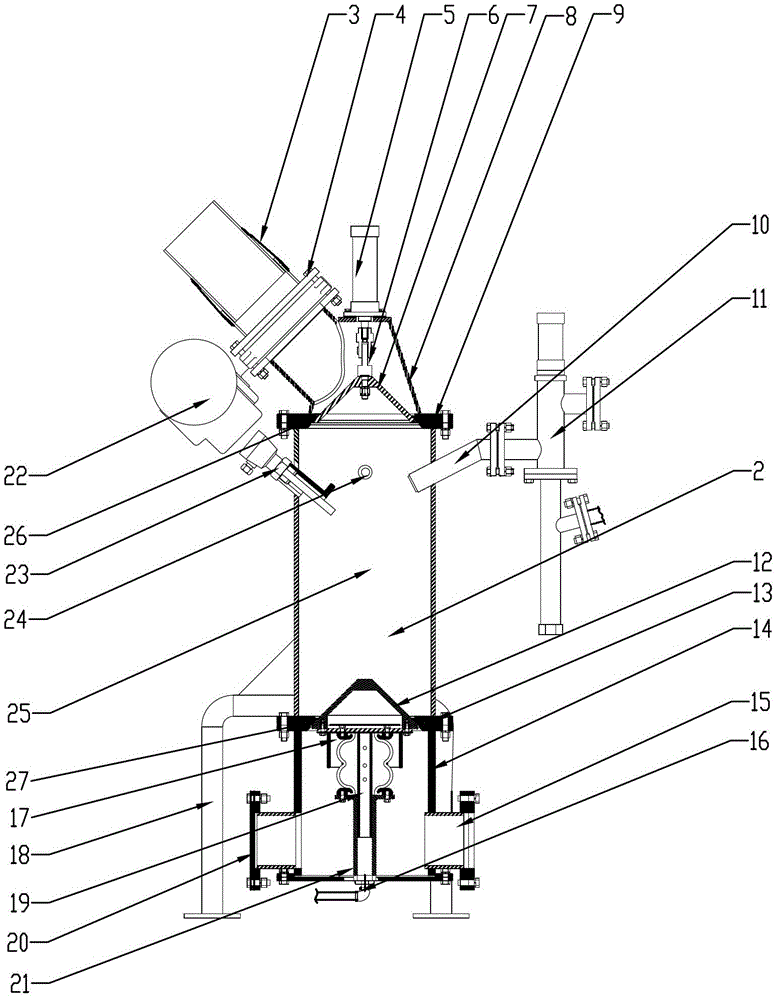

[0011] As shown in Figures 1 to 2, the present invention mainly includes two material tanks 2 connected to the outlet of the three-way feeding pipe 1. The material tank 2 includes a tank body 25 , the upper end of the tank body 25 is connected to the one-way feed pipe 8 through the upper flange 9 , and the lower end of the tank body 25 is connected to the discharge pipe 14 through the lower flange 13 . The side of the tank body 25 is connected to the intake and exhaust valve 11 through the intake and exhaust valve seat 10, which is mainly used for intake of compressed air and exhaust of residual air. The side of the tank body 25 is provided with a level gauge 23 and a pressure switch 24, the level gauge 23 is used to detect the material height in the tank body 25, and the pressure switch 24 is used to detect the pressure condition in the tank body 25. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com