Low-emissivity coated glass and manufacturing method thereof

A low-emissivity coating and manufacturing method technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem that the bottom dielectric layer is difficult to prevent glass diffusion, glass color is difficult to control, and processing efficiency is low And other problems, to achieve stable optical and thermal properties, not easy to appearance defects, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

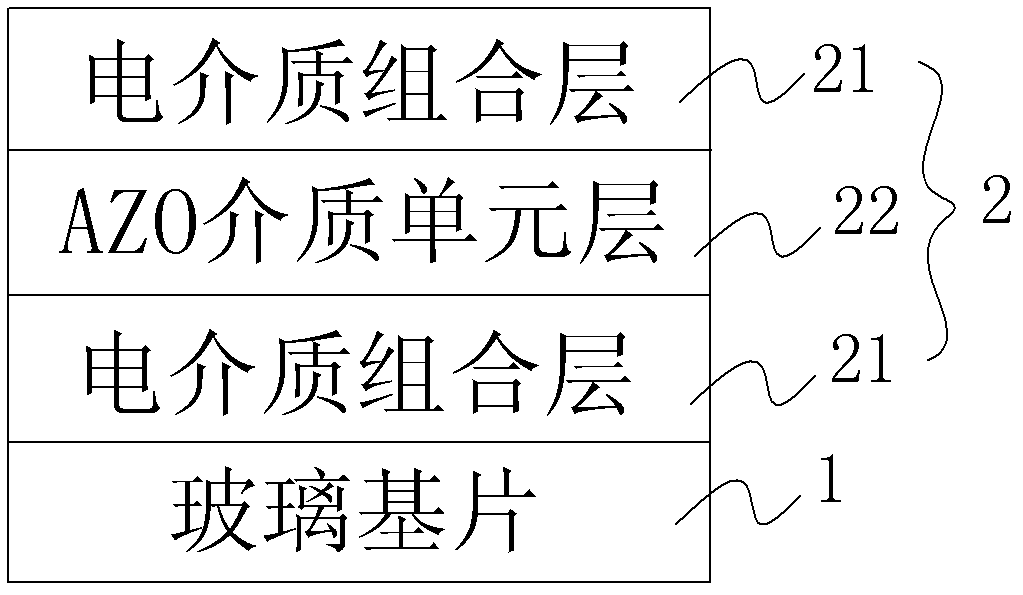

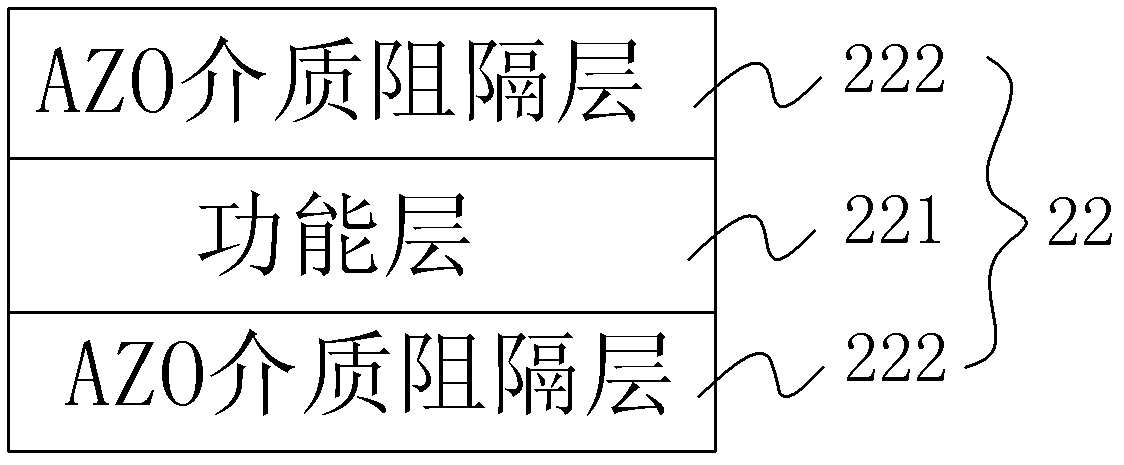

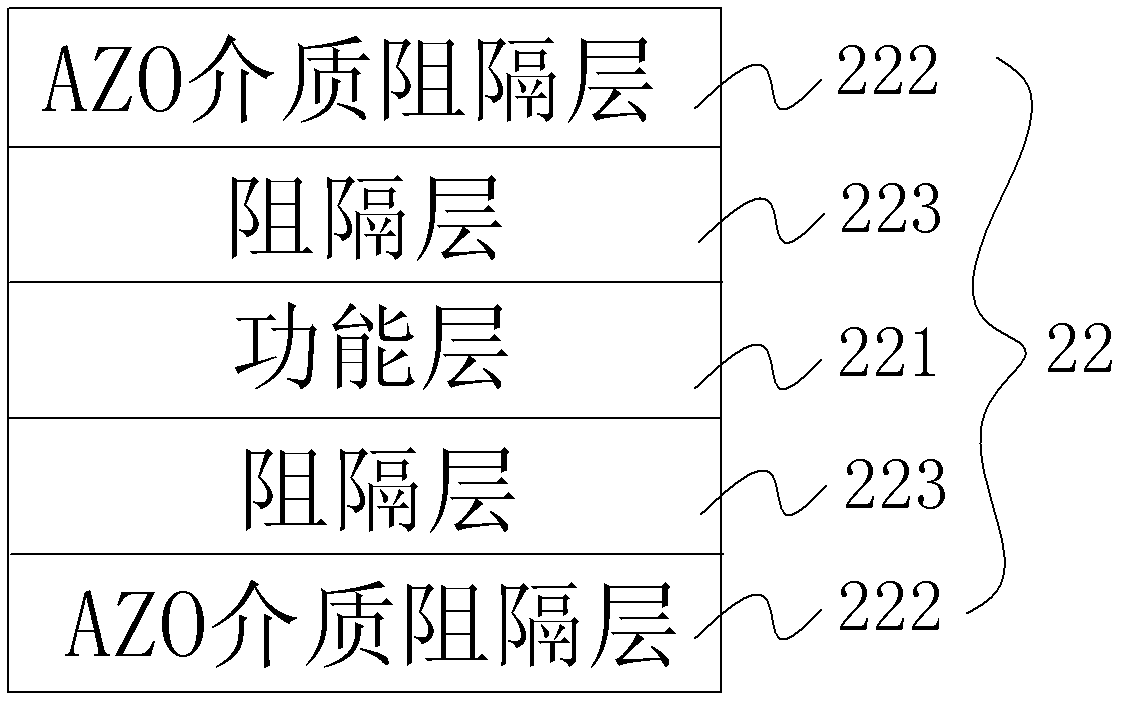

[0068] see figure 1 and Figure 2a ~ Figure 2b , figure 1 It is a structural schematic diagram of a coated glass according to an embodiment of the present invention, Figure 2a ~ Figure 2b It is a schematic diagram of the structure of the AZO dielectric unit layer in different embodiments of the present invention. Low-emissivity coating 2 glass, including a glass substrate 1 and a coating 2 coated on the glass substrate 1, the coating 2 includes a multilayer dielectric composite layer 21 and is arranged between adjacent dielectric composite layers 21 AZO dielectric unit layer 22 between them, wherein AZO is an aluminum-doped zinc oxide film, and the AZO dielectric unit layer 22 includes a functional layer 221 and an AZO dielectric barrier layer 222, and the AZO dielectric barrier layer 222 is laid on the functional layer 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com