Angle adjusting and clamping method for milling jig

A milling machine fixture and angle adjustment technology, which is applied in the direction of clamping, positioning devices, manufacturing tools, etc., can solve the problems of class A fixtures that are not universal, poor angle locking, waste of materials, etc., to save time for inclination angle adjustment and yield Improvement and good self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

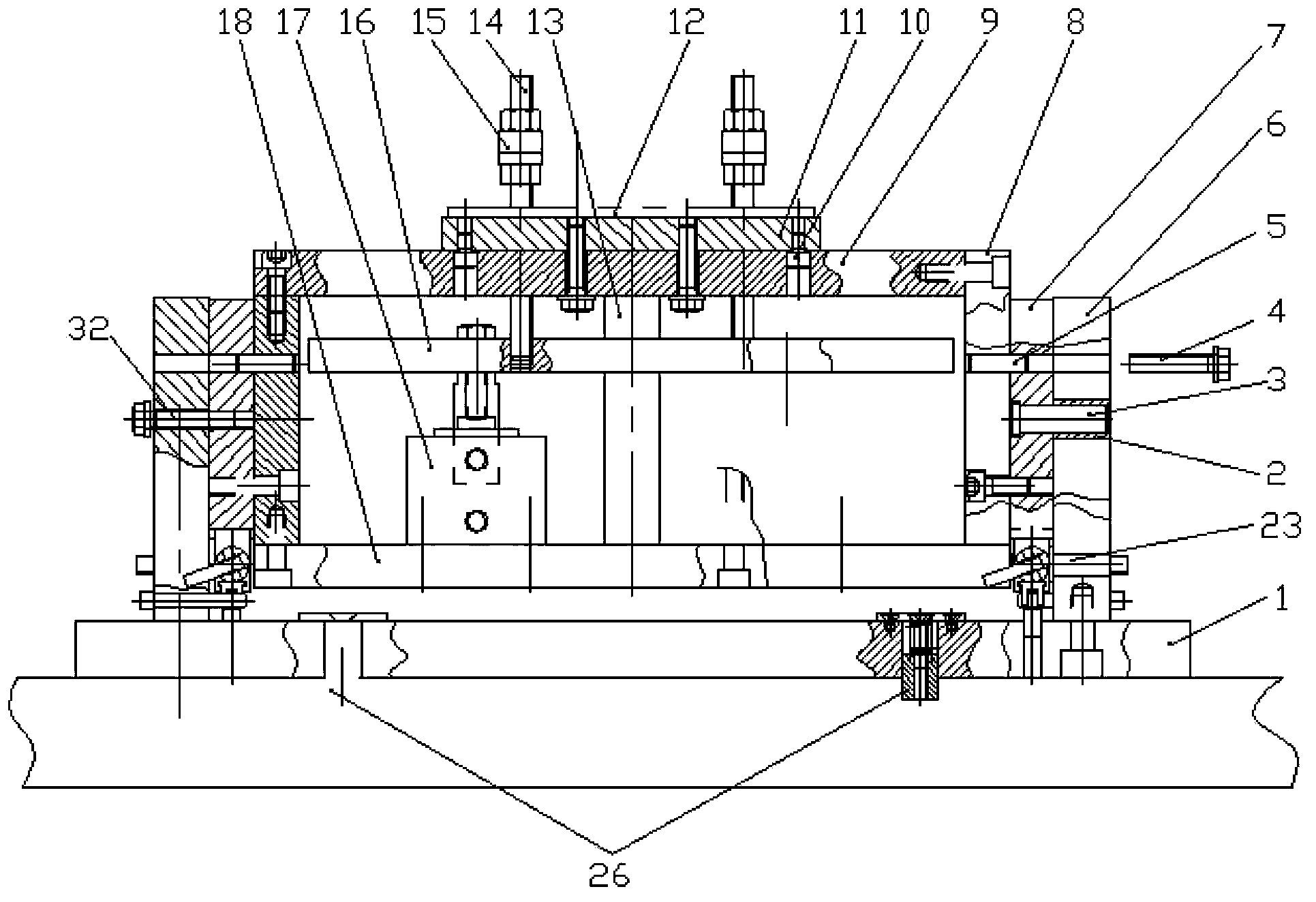

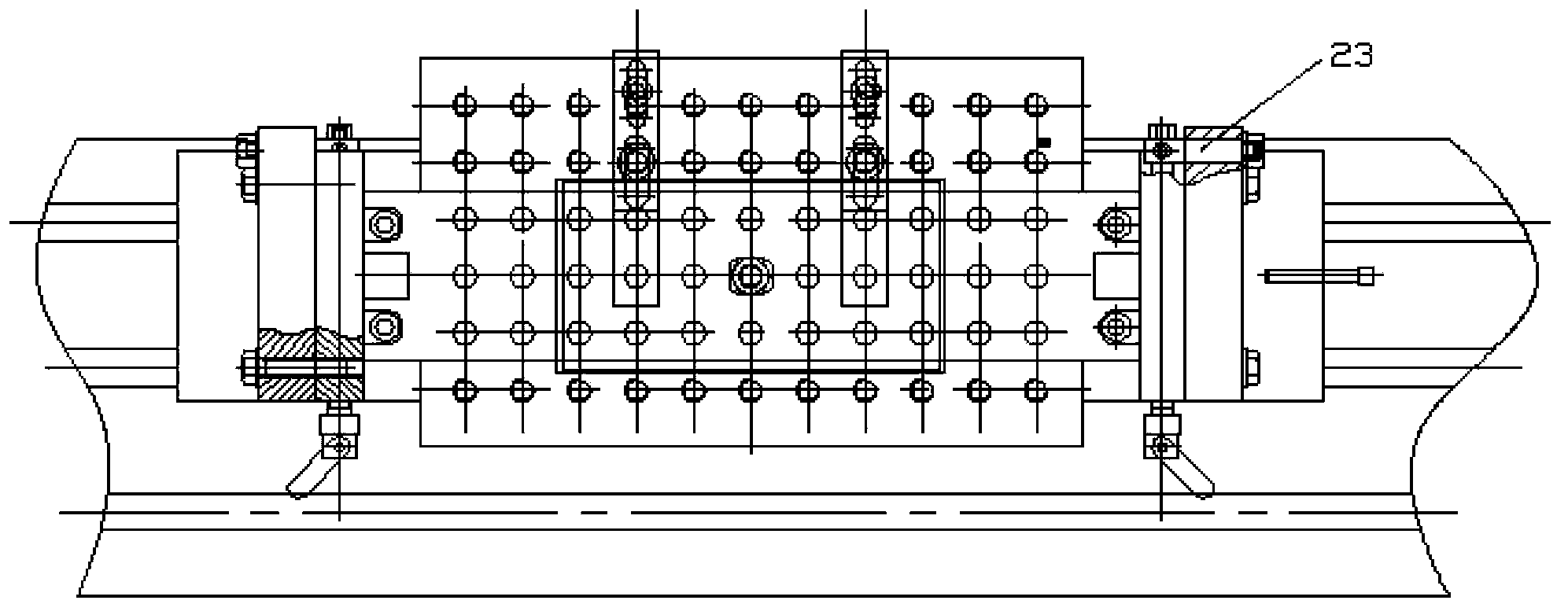

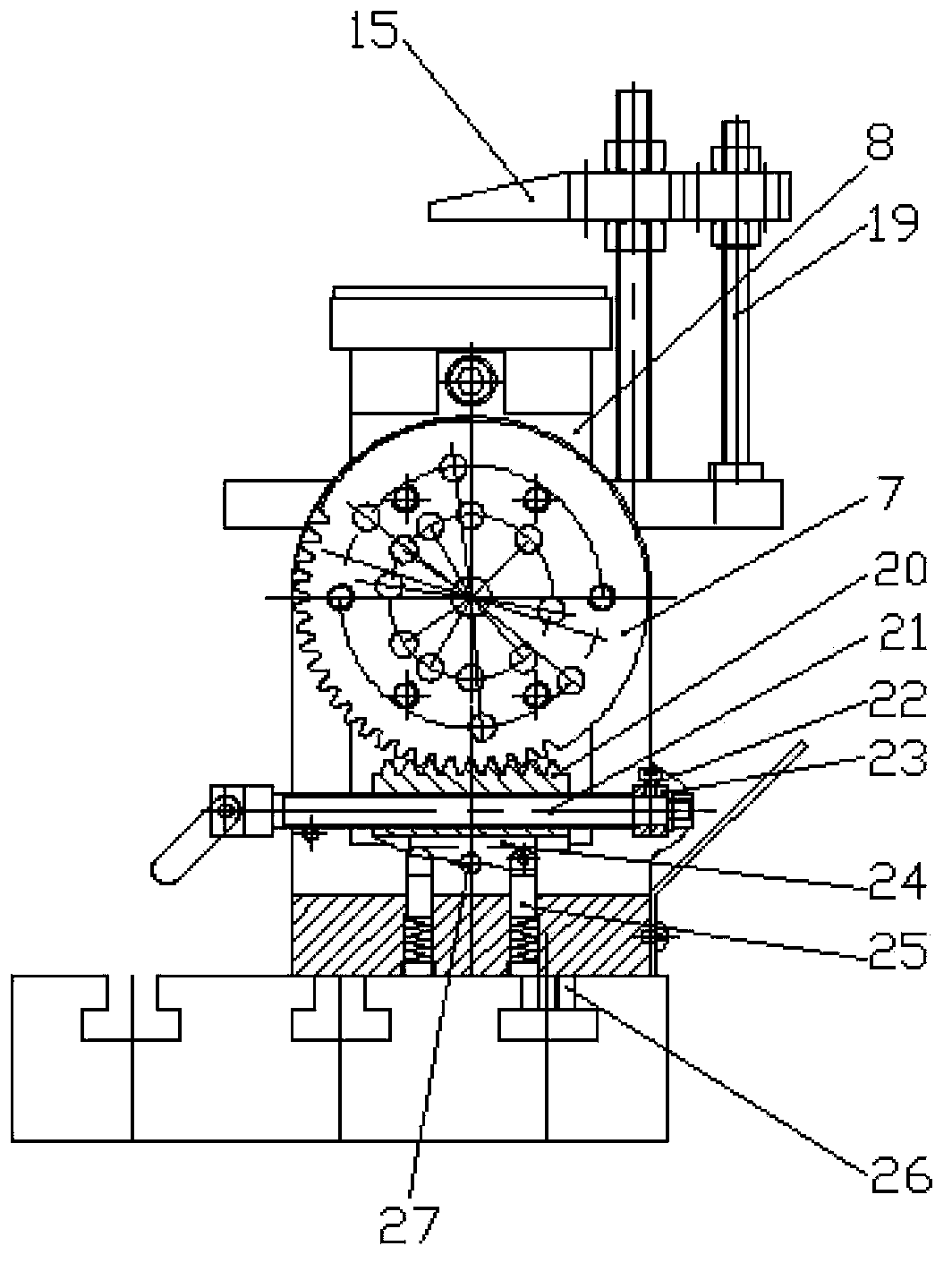

[0034] Figure 1 to Figure 4 The specific structure of the universal jig for fast positioning pneumatic pressing and fine adjustment of inclination angle is shown. It includes a bracket installed on the workbench 28, and a box body is rotatably connected to the bracket. The box body includes two side plates 8 parallel to each other, and the bottoms of the two side plates are vertically fixed to the base of the cylinder. On the seat plate 18, a top plate 9 is vertically fixed on the top of the two side plates, and the top plate 9 is the positioning panel of the flat fixture 11.

[0035] A flat clamp 11 is fixed on the top plate 9 , and the flat clamp 11 is used for installing a workpiece 12 . The flat fixture 11 is provided with workpiece positioning pins 31 for positioning the workpiece 12 . The flat clamp 11 is positioned on the top plate 9 of the box body through the stepped pin 10, and the flat clamp 11 and the top plate of the box body are fixed by bolts.

[0036] The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com