Equipment for preventing metal piece from adhering welding spatters

A technology for metal parts and spatter, which is applied in the field of metal anti-welding spatter treatment equipment, can solve the problems of no standard specification, reduce the work efficiency of welding operators, and prevent tools from receiving spatter, etc., and achieve high automation intensity and high degree of automation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

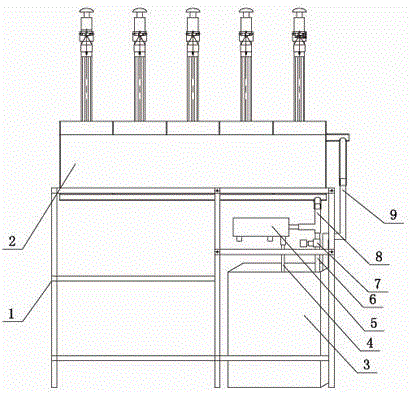

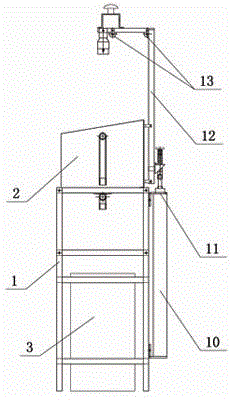

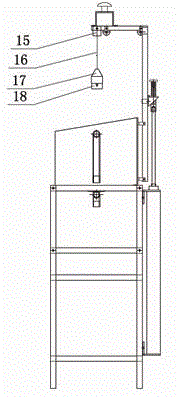

[0035] A device for preventing metal parts from sticking to welding spatter, the structure of which is as follows figure 1 and figure 2 As shown, it includes a frame 1, a storage box 2, a soaking device and a taking-out device.

[0036] The storage box 2 is fixedly connected above the frame 1 .

[0037] The soaking device is used to soak the surface of the metal parts with anti-splash agent, and includes a liquid storage tank 3, a water pump 5 and a first control circuit.

[0038] The liquid storage tank 3 is arranged on the ground, and the water pump 5 is fixed on the frame 1 . The water pump 5 and the liquid storage tank 3 are connected by the first water inlet pipe 4, the water pump 5 and the storage box 2 are connected by the second water inlet pipe 8, the liquid storage tank 3 and the storage box 2 are connected by the overflow pipe 9 and the drain pipe 6 . The solenoid valve 7 with delayed start is provided on the drain pipe 6 .

[0039] The first control circuit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com