Automatic interior-angle chamfering machine

An internal angle machine and automatic technology, applied in the direction of driving devices, metal processing machinery parts, clamping, etc., can solve the problems of high labor intensity, high cost, low work efficiency, etc., to reduce labor intensity, improve service life, and automation intensity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

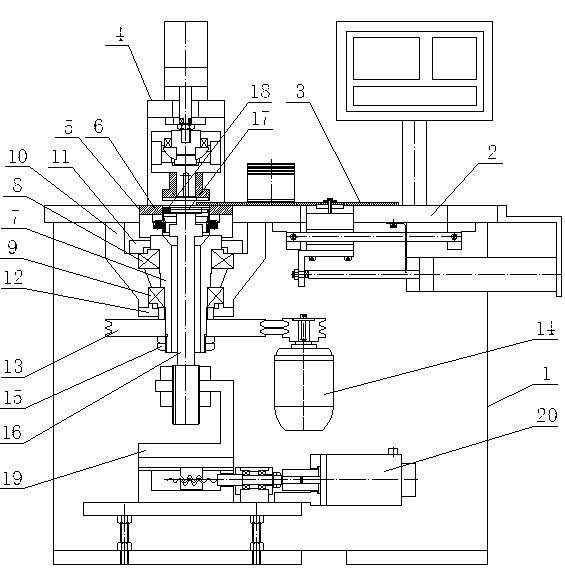

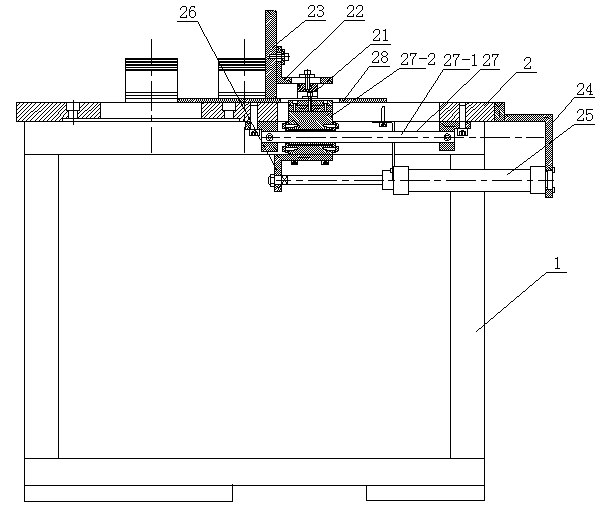

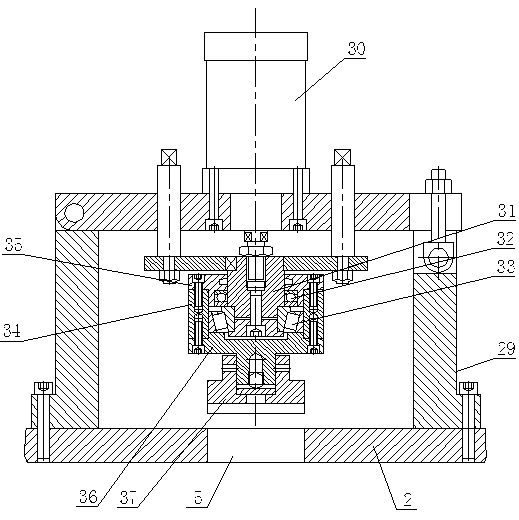

[0013] like figure 1 As shown, it is an automatic chamfering machine, including a frame 1, a panel 2 is set above the frame 1, a feeding device 3 and a pressing device 4 are set on the panel 2, a mold installation port 5 is set on the panel 2, and the mold installation port 5 The mold 6 is set, the hollow main shaft 7 is connected to the bottom of the mold 6, the hollow main shaft 7 is connected to the main shaft mounting seat 10 through the upper tapered roller bearing 8 and the lower tapered roller bearing 9, the main shaft mounting seat 10 is connected to the panel 2, and the mold 6 is set on the main shaft In the mounting seat 10, an upper bearing gland 11 is arranged above the upper tapered roller bearing 8, and the upper bearing gland 11 is connected with the main shaft mounting seat 10, and a lower bearing gland 12 is arranged below the lower tapered roller bearing 9, and the lower bearing The cover 12 is connected with the spindle mounting base 10 . The hollow main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com