Temperature adjustable electric iron and temperature adjustment method thereof

An electric soldering iron and temperature adjustment technology, which is applied in soldering irons, metal processing equipment, welding equipment and other directions, can solve the problem of high cost of temperature-adjustable electric soldering irons, and achieve the effects of improving welding work efficiency, good thermal conductivity and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

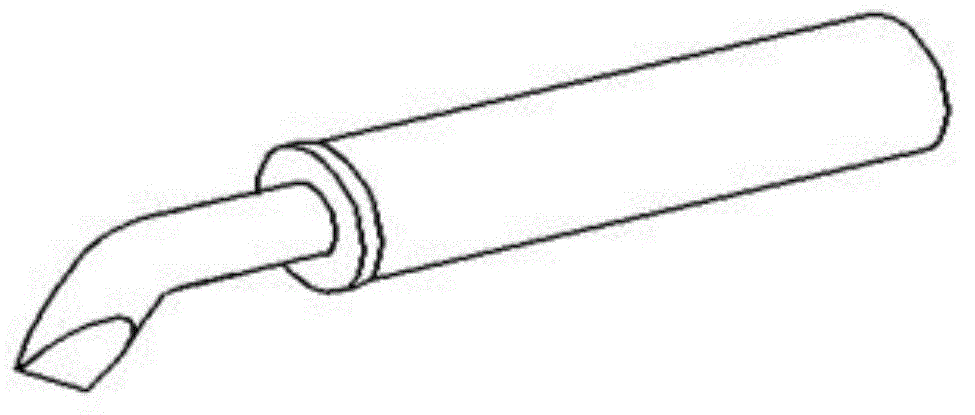

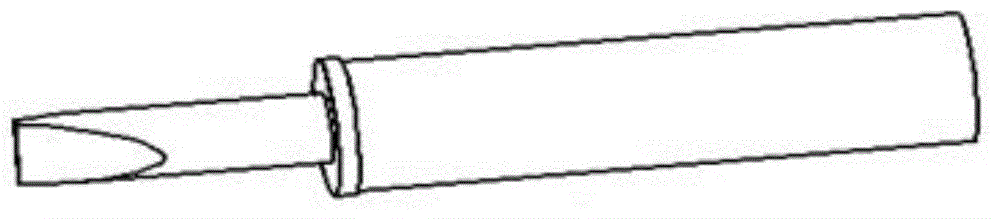

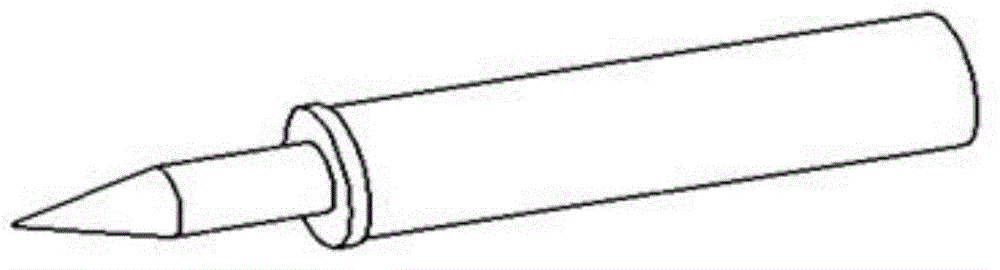

[0021] Commonly used soldering iron tips such as Figure 1-a , 1-b , 1-c and 1-d, where Figure 1-c and 1-d The two types of soldering iron tips are mostly used for welding and dismantling tiny integrated circuit pins and electronic separation components. In order to realize the temperature-adjustable function of ordinary electric soldering irons, the present invention provides a temperature-adjustable electric soldering iron, such as figure 2 As shown, the temperature-adjustable electric soldering iron of the present invention includes an electric soldering iron handle 1 and an electric soldering iron heating rod 2, a copper wire is wound on the electric soldering iron heating rod 2, and one end of the copper wire is wound from the head of the electric soldering iron heating rod 2, so The other end of the copper wire is drawn out at a set angle along the extension direction of the electric soldering iron heating rod 2 to obtain the working end 3 of the adjustable temperatu...

Embodiment 2

[0025] like Figure 4 As shown, the temperature-adjustable electric soldering iron of the present invention includes an electric soldering iron handle 1 and an electric soldering iron heating rod 2. The inside of the electric soldering iron heating rod 2 is provided with a copper wire through an adjustable bolt 4, and one end of the copper wire is connected to the inside of the electric soldering iron heating rod 2. In close contact, the other end of the copper wire is drawn out at a set angle along the extension direction of the electric soldering iron heating rod 2 to obtain the working end 3 of the adjustable temperature welding head. The included angle of the extension direction is between 0° and 70°. When the electric soldering iron is powered on, the heat transfer of the electric soldering iron heating rod 2 is set on the copper wire inside it, and the heat is transferred to the working end 3 of the adjustable temperature welding head through the heat transfer copper wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com