Anaerobic-aerobiotic repairing method of TNT (Trinitrotoluene) contaminated soil

A technology for polluted soil and remediation methods, applied in the field of anaerobic-aerobic remediation, can solve problems such as no better, and achieve the effects of easy conversion, safe and reliable water sealing, and good remediation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The concentration of pollutants in a polluted soil is (1000.24±105.56) mgTNT / kg soil, and the pollution is concentrated in the soil 20cm away from the surface. Now adopt the embodiment of the present invention to remediate its polluted soil. At the same time, take another portion of TNT-contaminated soil in the polluted site and add inactivated sludge as the control group. TNT was determined by HPLC method, and a total of 10 samples were collected in each group for analysis and then the average was calculated.

[0034] Excavate the surface polluted soil, air-dry, grind into granules, pass through a 2cm sieve,

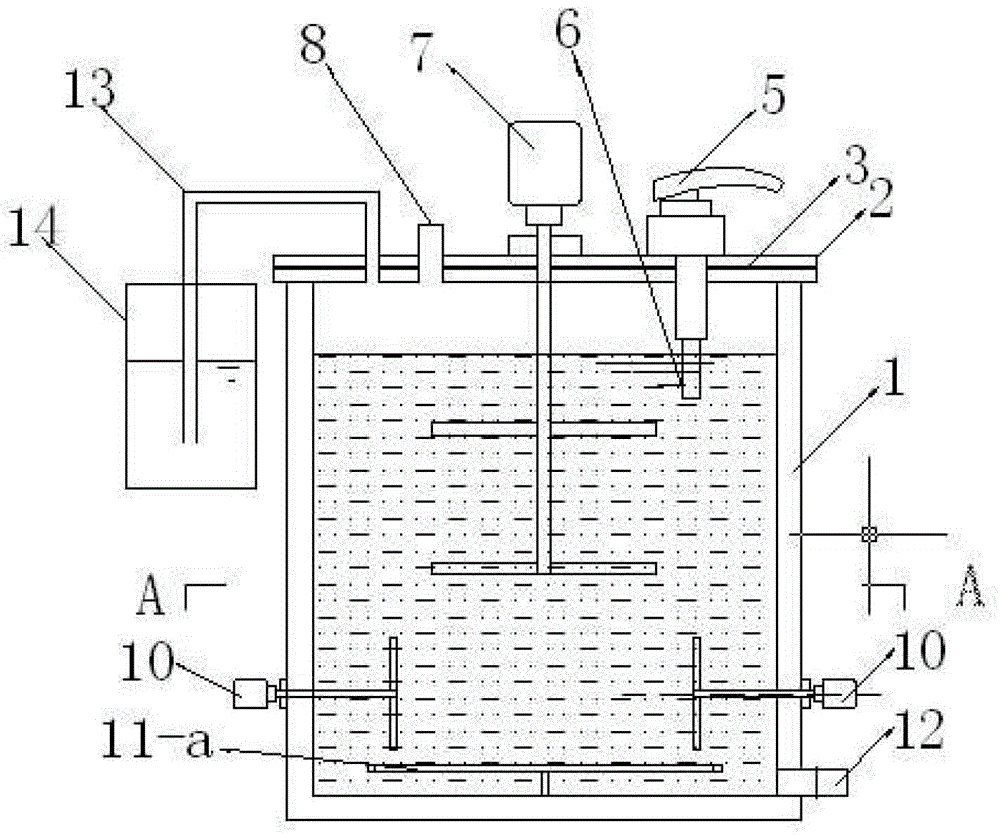

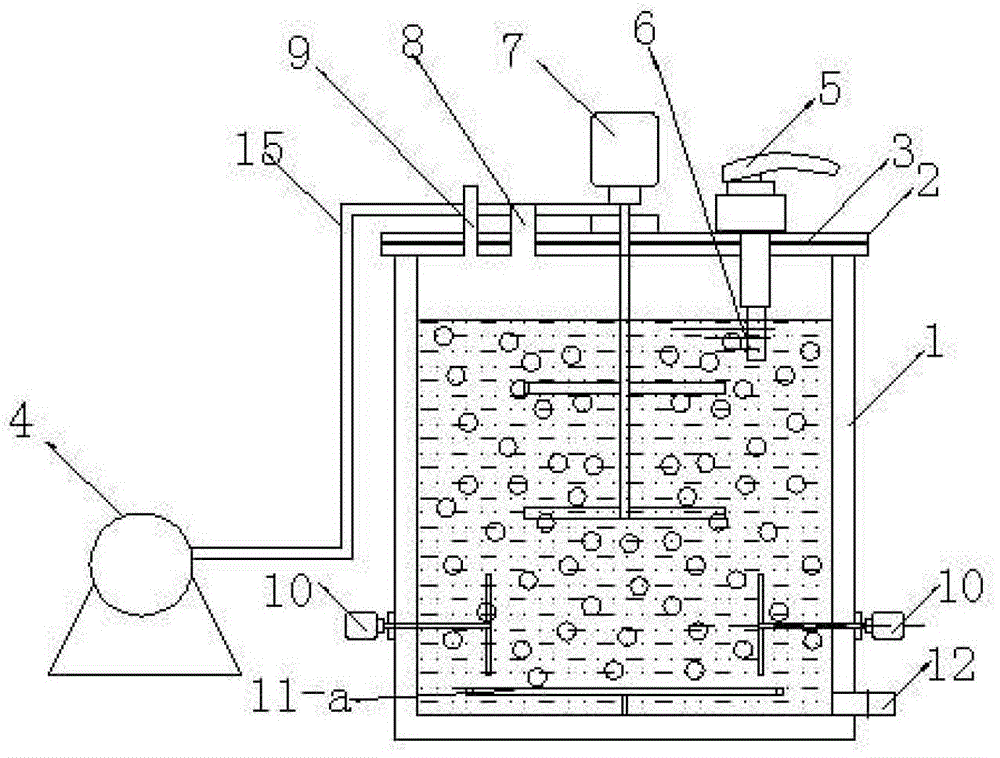

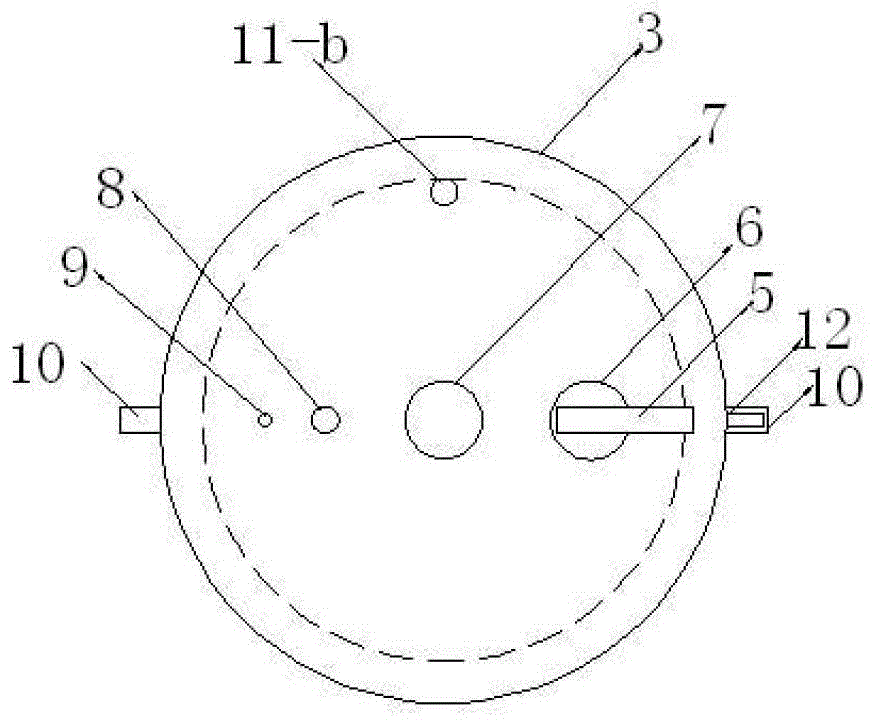

[0035] Take the above-mentioned anaerobic-aerobic compatible reactor with a volume of 5L (20cm high, 18cm internal diameter), close the air compressor 4 of the anaerobic-aerobic biological sludge reactor, and seal the aeration inlet 11-b , and connect the water seal 14, then fill nitrogen therein, and add sterile deoxygenated water, after the oxygen in the reac...

Embodiment 2

[0039] The TNT concentration in the soil near a TNT production factory is 3000±130mg / kg soil, and the pollution is concentrated in the soil 25cm away from the surface. Now adopt the embodiment of the present invention to remediate its polluted soil. At the same time, take another portion of TNT-contaminated soil in the polluted site and add inactivated sludge as the control group. TNT was determined by HPLC method, and a total of 10 samples were collected in each group for analysis and then the average was calculated.

[0040] Excavate the surface polluted soil, air-dry, grind into granules, pass through a 2cm sieve,

[0041] Take the above-mentioned anaerobic-aerobic compatible reactor with a volume of 20L (20cm high, 18cm inner diameter), close the air compressor 4 of the anaerobic-aerobic biological sludge reactor, and seal the aeration inlet 11-b , and connect the water seal 14, then fill it with nitrogen, and add sterile deoxygenated water, after the oxygen in the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com