Pipeline pressure test and pulse cleaning integrated equipment

An integrated equipment and pulse cleaning technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, using stable tension/pressure to test the strength of materials, etc., can solve the problems of inability to meet hose quality requirements, multiple processes, secondary pollution, etc. problems, achieve the effects of saving equipment purchase costs, high flushing efficiency, and saving consumable costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method of the present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings.

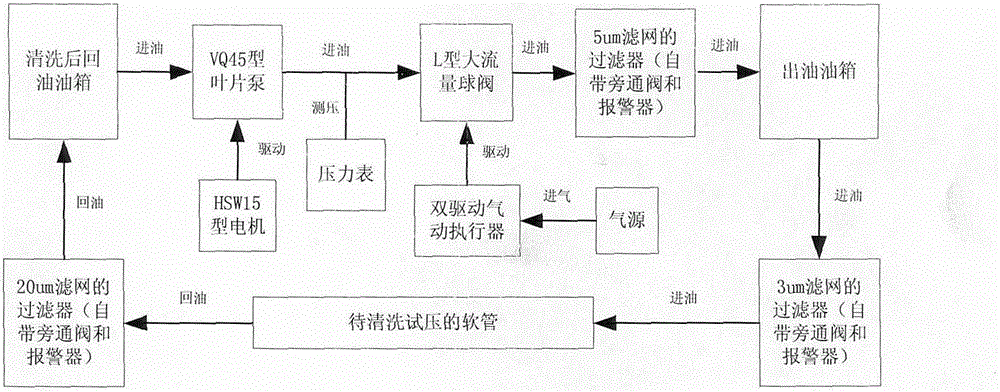

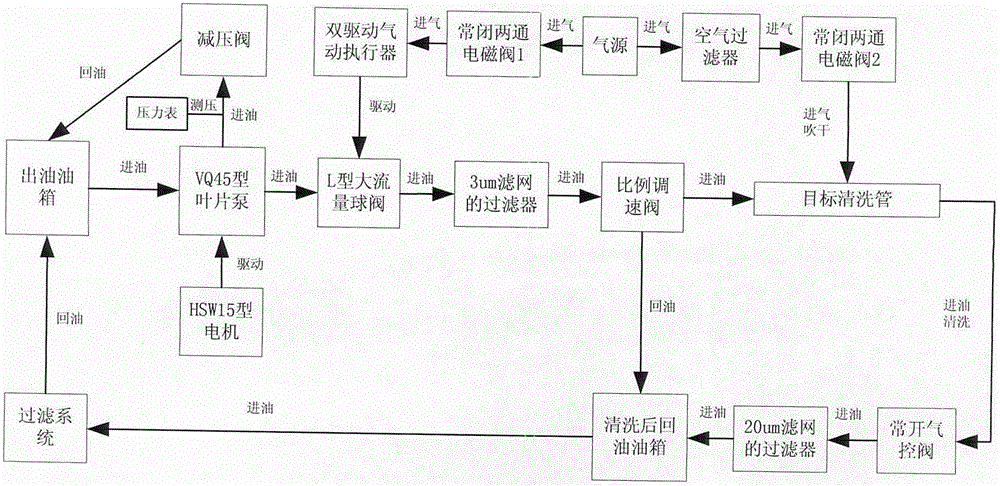

[0031] figure 1 It is a schematic diagram of the overall structure of the system of the present invention, including a hydraulic oil filtration system, a pipeline cleaning and drying system, a pipeline high-pressure pressure test system, an automatic door system, PLC monitoring and an operating system. The hydraulic oil filtration system is responsible for filtering the hydraulic oil to ensure the cleanliness of the hydraulic oil. The pipeline cleaning and drying system is responsible for cleaning and drying the hose, using pressure sensors and flow sensors to send relevant data and signals to the PLC monitoring and operating system, and receiving control signals from the PLC monitoring and operating system After that, it drives related executive components, such as solenoid valves, proportional speed control valves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com