Semiconductor failure detection structure and formation method, method for detecting failure time

A technology for detecting structure and failure time, which is applied in semiconductor/solid-state device testing/measurement, semiconductor devices, semiconductor/solid-state device components, etc. It can solve the problem of low accuracy of electromigration failure detection structure testing and damage to standardized pad structures, etc. problems, to avoid the expansion of the design area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The inventors found that in the existing electromigration failure detection structure, the accuracy of the test results is reduced due to the parallel connection of each metal layer in the semiconductor device due to the standardized pad structure of the loading point and the test point.

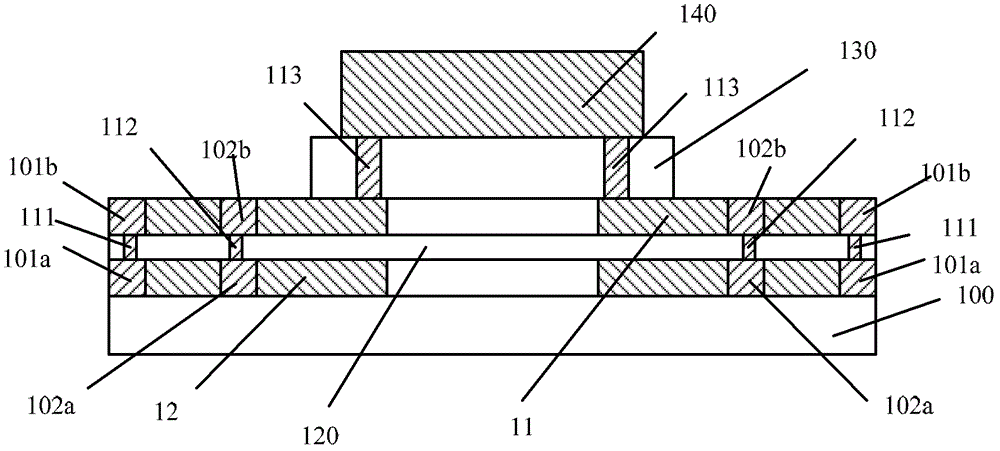

[0055] Specifically, such as figure 1 As shown, the test pad 102 and the test plug 112 form a test pad structure, and the loading pad 101 and the loading plug 111 form a loading pad structure. The pad structure is a standardized structure, which is used to perform various performance tests on each metal layer during the manufacturing process of the semiconductor device, and cannot be removed or damaged in a general process.

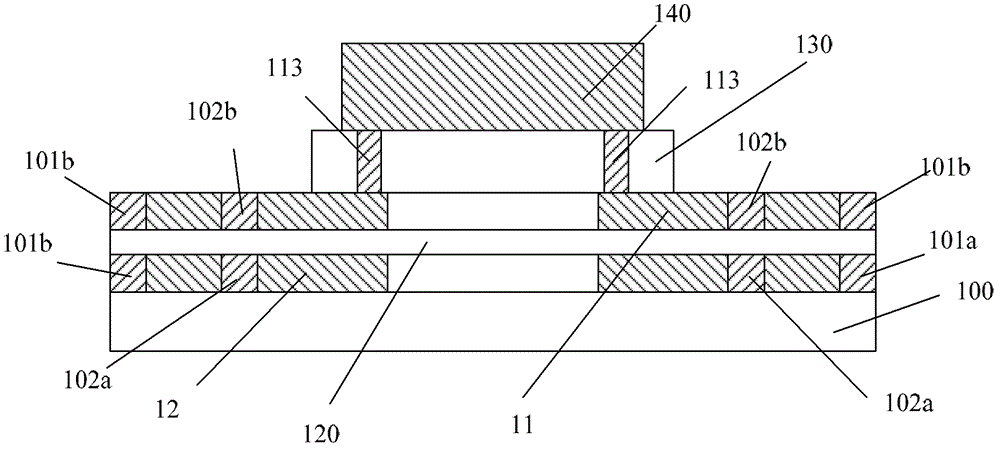

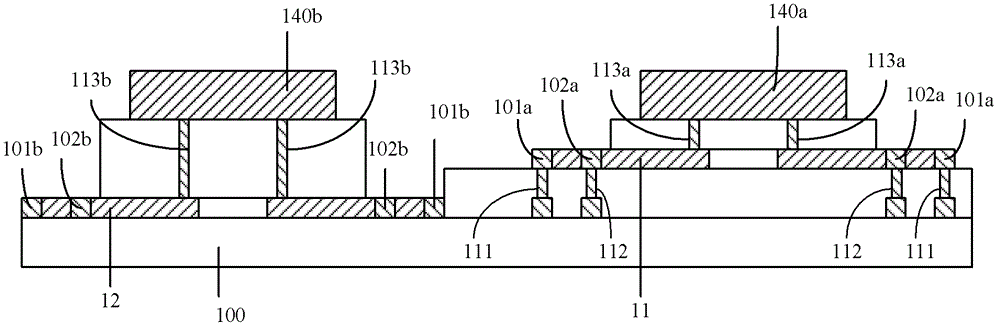

[0056] The inventor found through further research that two existing improvements to the electromigration failure detection structure can improve the accuracy of the electromigration test structure.

[0057] Specifically, the first improvement method takes fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com